Outer packaging material for power storage device, method for producing same, and power storage device

A technology for power storage devices and outer packaging, which is applied in the manufacture of secondary batteries, hybrid/electric double-layer capacitors, lamination devices, etc. and insulation reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2 and comparative example 1、2

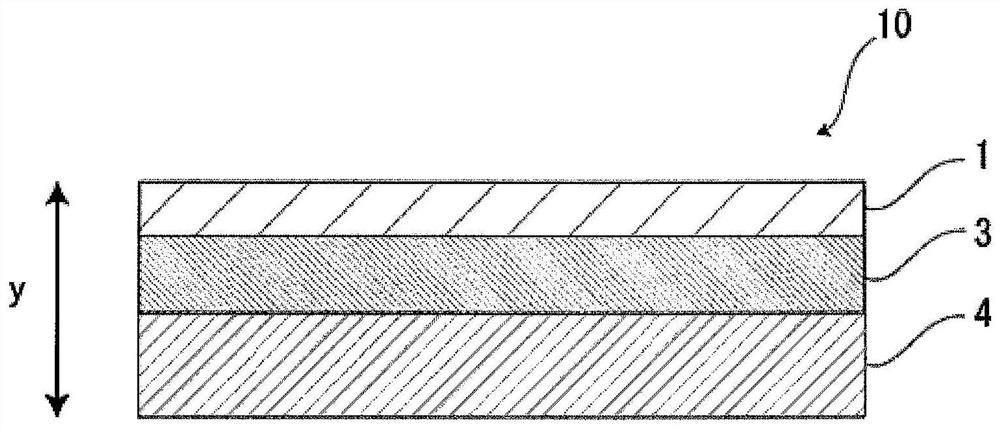

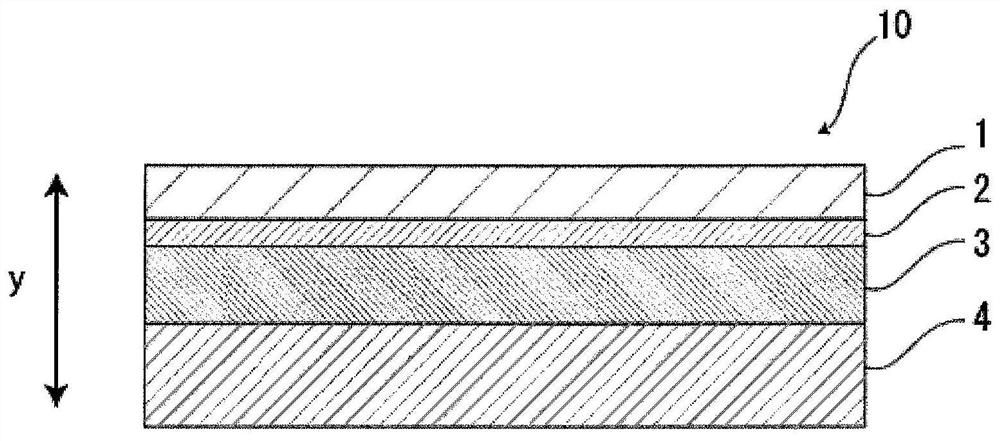

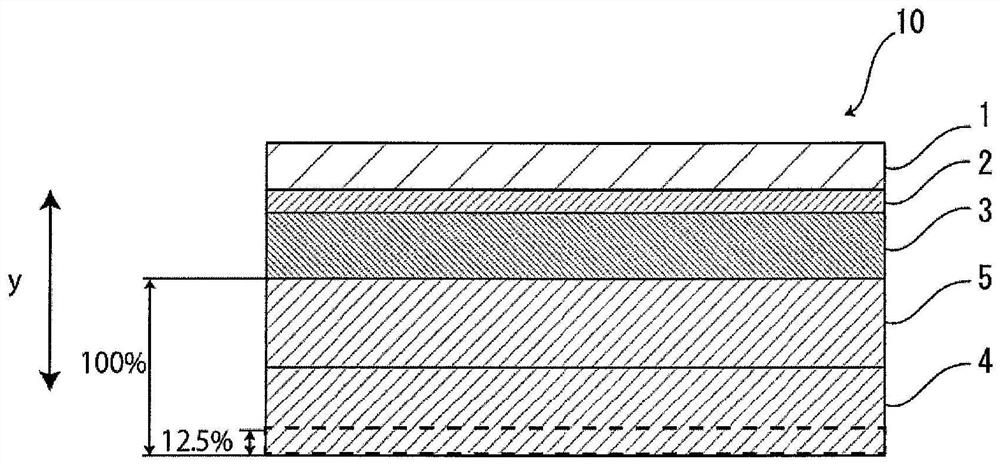

[0164] A polyethylene terephthalate (PET) film (thickness 12 μm) and stretched nylon (ONy) film (thickness 15 μm) were prepared, and a two-component polyurethane adhesive (polyol compound and aromatic Group isocyanate-based compound) (3 μm), bonded to ONy film as a substrate layer. In addition, an aluminum alloy foil (JIS H4160: 1994A8021H-O (40 μm in thickness)) was prepared as a barrier layer. Next, a two-component polyurethane adhesive (polyol compound and aromatic isocyanate compound) was applied to one surface of the aluminum alloy foil to form an adhesive layer (thickness: 3 μm) on the barrier layer. Next, after laminating the adhesive layer on the barrier layer and the substrate layer (ONy film side) by dry lamination, aging treatment is performed to manufacture a substrate layer / adhesive layer / barrier layer laminate. layers. Chemical surface treatment was performed on both sides of the aluminum alloy foil. The chemical method surface treatment of aluminum alloy foil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com