Floor brush for floor scrubber and floor scrubber

A floor washing machine and local technology, applied in application, carpet cleaning, floor cleaning, etc., can solve problems such as poor user experience, inability to completely remove water stains, residues, etc., achieve good commercial significance, and solve sewage residues , the effect of simple product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

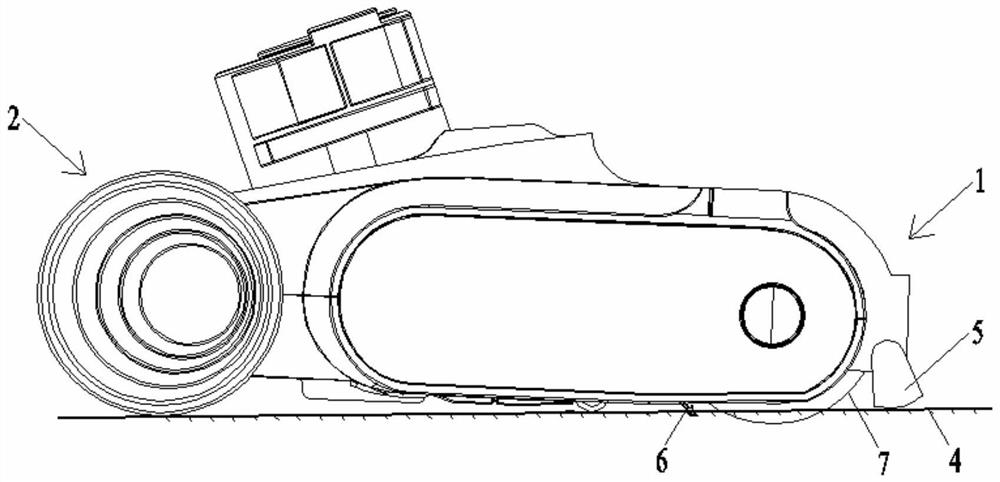

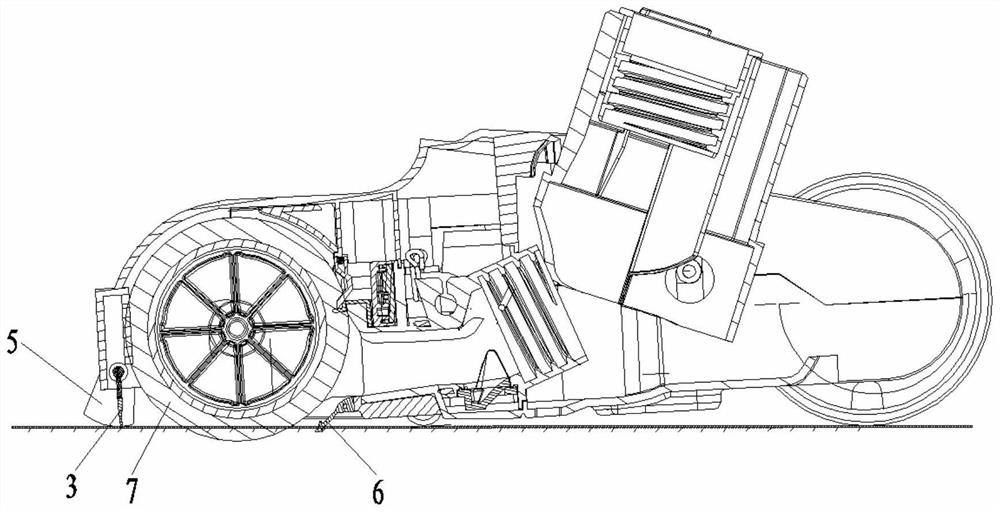

[0045] see Figure 1~4 As shown, a ground brush for a floor washing machine has a front end 1 and a rear end 2, and the front end of the ground brush is provided with a scraper 3; the scraper has at least two working positions as follows :

[0046] (1) Wiping position: when the ground brush moves backward, the scraping bar becomes basically downward, and the bottom end of the scraping bar is against the surface to be cleaned to scrape off the water stains on the surface to be cleaned ;

[0047] (2) Suspended working position: when the ground brush moves forward, the scraping strip becomes suspended, and the bottom end of the scraping strip is away from the surface to be cleaned.

[0048] It also includes a driving mechanism, which includes two balance wheels 5, and the balance wheels are arranged on both sides of the scraping strip; the upper end of the balance wheel is coaxially arranged with the rotating shaft of the scraping strip, and the balance wheel The lower end sur...

Embodiment 2

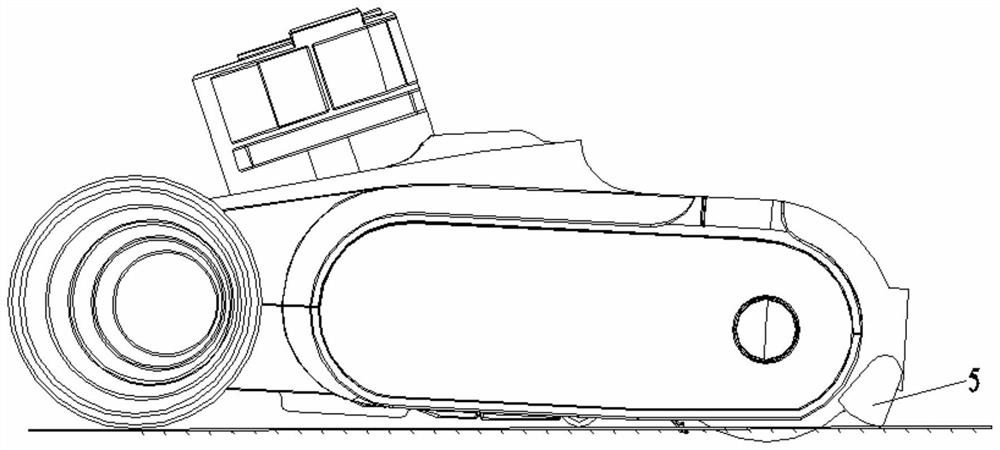

[0057] see Figure 5-8 As shown, a ground brush for a floor washing machine has a front end 1 and a rear end 2, and the front end of the ground brush is provided with a scraper 3; the scraper has the following two working positions:

[0058] (1) Wiping position: when the ground brush moves backward, the scraping bar becomes basically downward, and the bottom end of the scraping bar is against the surface to be cleaned to scrape off the water stains on the surface to be cleaned ;

[0059] (2) Suspended working position: when the ground brush moves forward, the scraping strip becomes suspended, and the bottom end of the scraping strip is away from the surface to be cleaned.

[0060] It also includes a driving mechanism, and the scraping strip is driven and connected by the driving mechanism to form the above two working positions. The driving mechanism includes an electromagnetic drive part and two swinging pieces 8, and the swinging pieces are arranged on both sides of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com