Mining optical fiber temperature measurement and fire extinguishing control system

A control system, optical fiber temperature measurement technology, applied in thermometers, measuring devices, fire rescue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

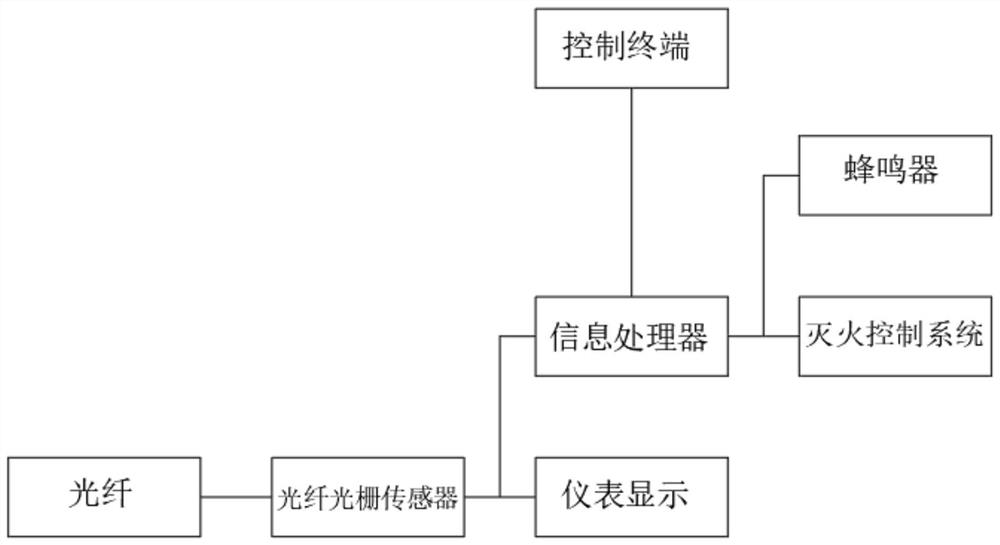

[0041] see figure 1 , this embodiment further explains other embodiments, a mining optical fiber temperature measurement and fire extinguishing control system, including a fiber grating sensor, the fiber grating sensor is installed on the optical fiber by embedding, the fiber grating sensor performs temperature display through an instrument, and the fiber grating sensor The grating sensor performs signal processing through the information processor, and the information processor performs setting operations through the control terminal, and the information processor is connected with the buzzer and the fire control system respectively.

[0042] see figure 1 , the number of fiber grating sensors shall not be less than 30, and the distance between adjacent sensors shall not exceed 100 meters.

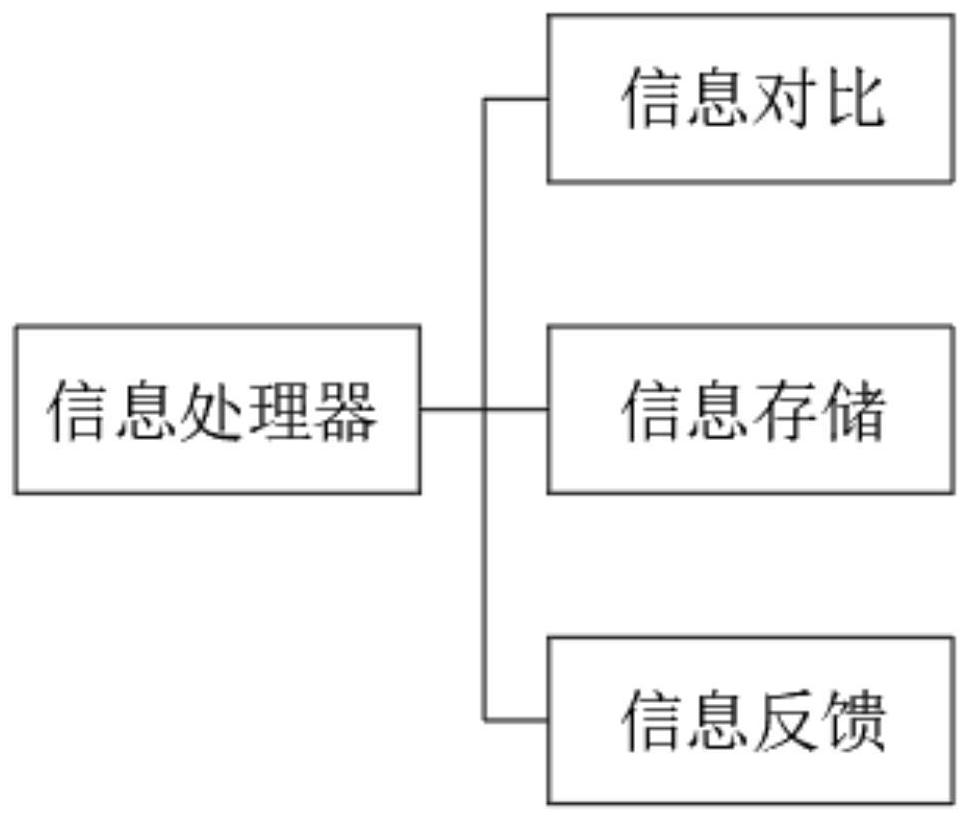

[0043] see figure 1 and figure 2 , the information processor includes information comparison, information storage and information feedback.

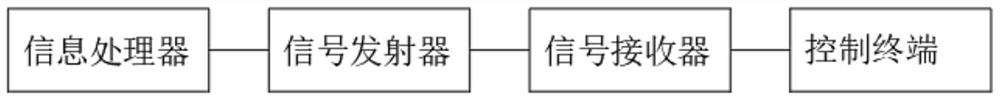

[0044] see figure 1 and image 3 An ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com