Dual-drive horizontal dual-purpose pay-off device

A pay-off device and dual-drive technology, applied in the field of dual-drive horizontal dual-purpose pay-off devices, can solve the problems of cable damage, inability to adapt to different sizes, and reduced pay-off efficiency, so as to achieve a safe and good pay-off process. Support effect, effect of reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

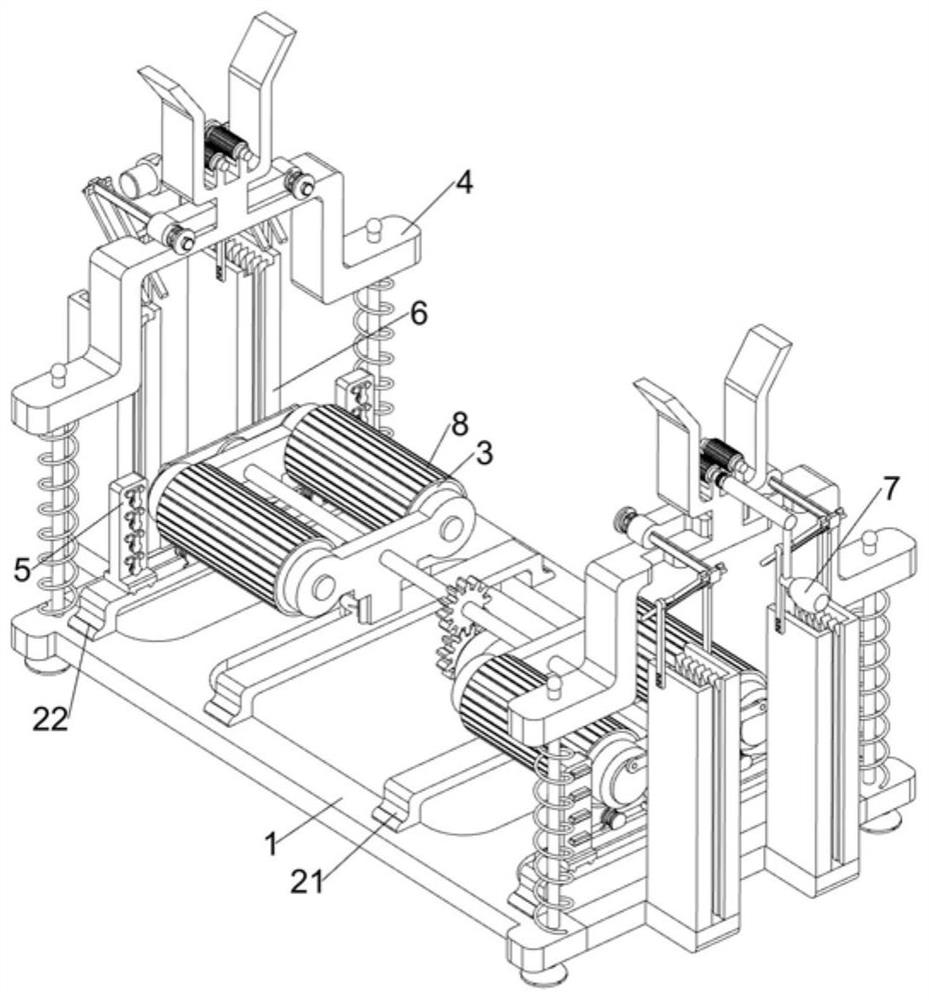

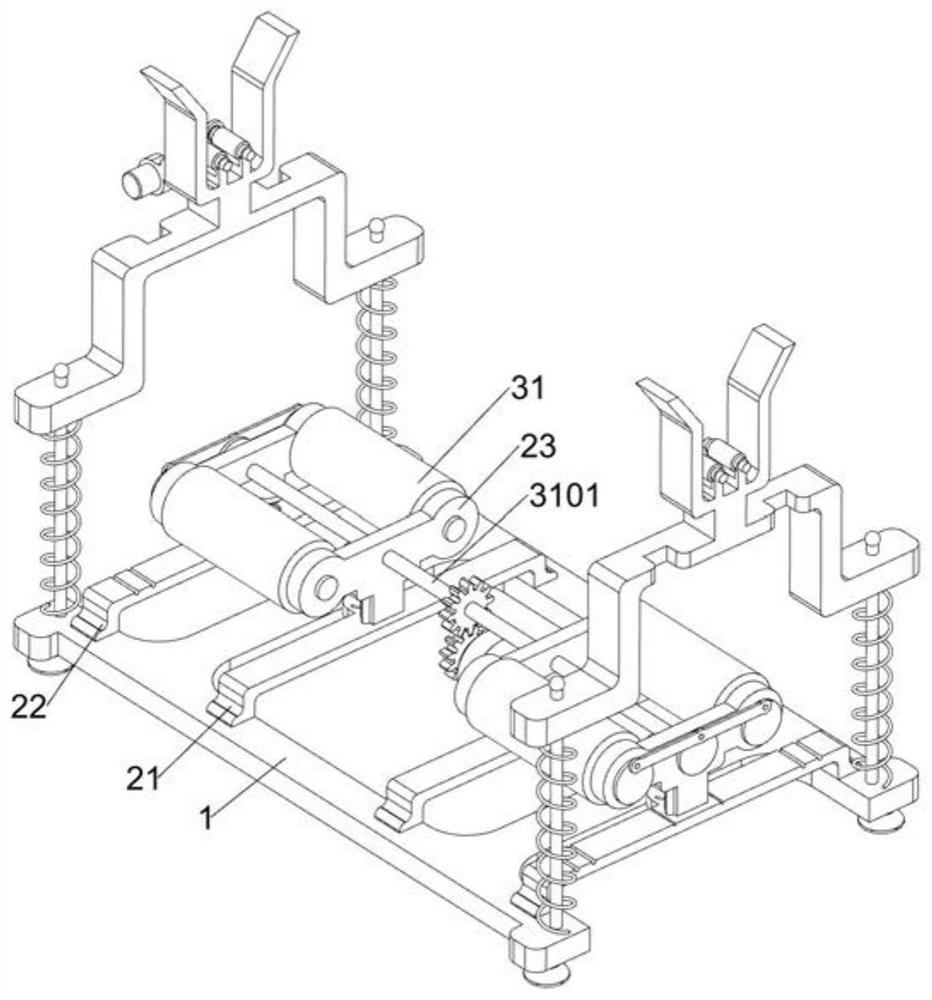

[0047] Actinomyces dual horizontal dual drive means, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Shown, it comprises a bottom support frame 1, C-shaped support 21, C-shaped slot plate 22, a T-shaped slide plate 23, stretching spring 24, drive assembly 3 and the chassis assembly drive shaft 4, a top solid bottom bracket connected to a pair of C-shaped support 21, fixed to the top of the bottom bracket 1, a pair of C-shaped slot plate 22, the support frame C-shaped slot 22 and the C-shaped plate 21 above the middle are slidably connected to the slide plate 23 is T-shaped, T-shaped slide plate 23 is connected between each adjacent C-shaped support plate 21 and the C-shaped slot 22 and the telescopic spring 24, the slide 3 is provided with chassis drive assembly 23 on the T-plate, tray drive assembly 3 with rotation of the drive cable tray, the bottom of the support frame 4, the drive shaft 4 for driving the cable drum assembly rack drive assembly is provid...

Embodiment 2

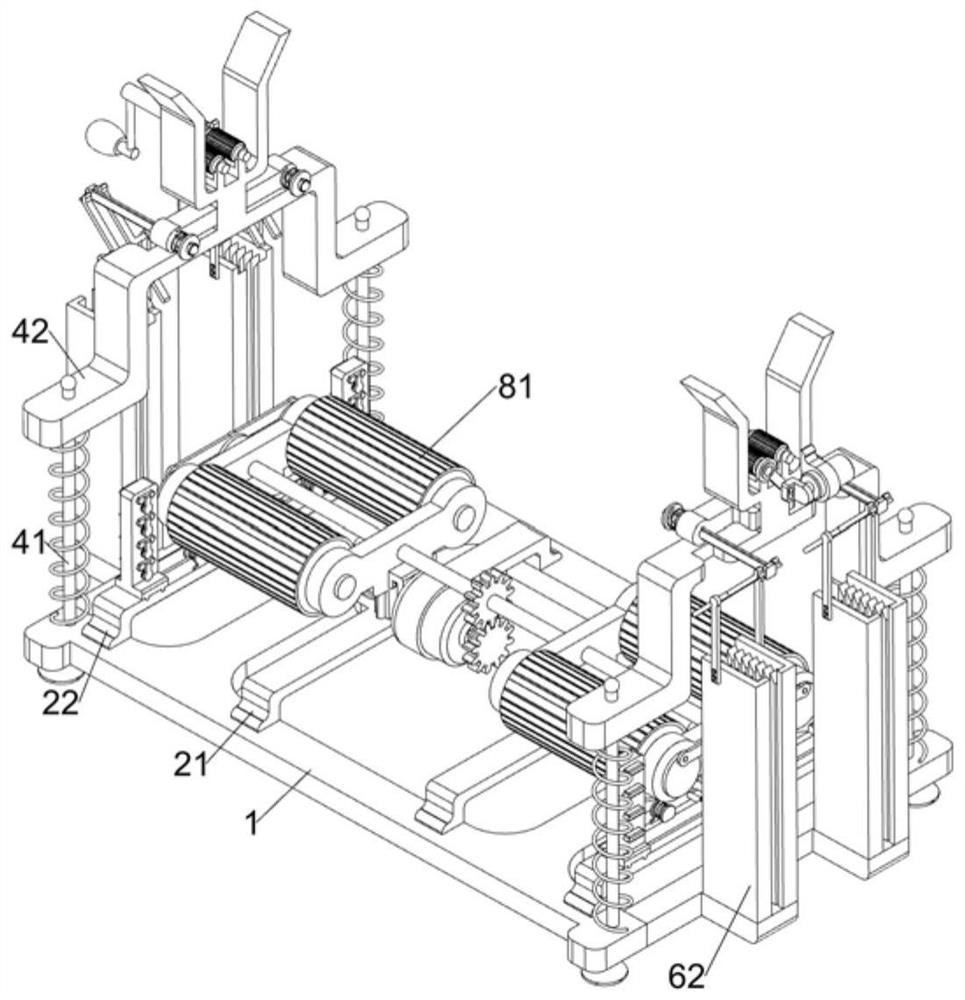

[0052] On the basis of Example 1, such as Figure 7 , Figure 8 and Figure 9 Shown, further comprising a support assembly 5 adaptable adaptive support assembly 5 is provided on the C-shaped slot plate 22, the support assembly 5 can be adaptive so that the apparatus is suitable for different diameters of cable tray, supporting assembly 5 adaptability comprising a wedge pressing plate 51, the connecting plate 52, the tension spring 521, the slide frame 53 T-shaped, L-shaped slide plate 54 and a return spring 55, above the C-shaped slot plate 22 slidably connected to a pair of wedge-shaped pressing plate 51 , the pressing plate 51 is provided with an upper inclined surface of the wedge, the wedge pressing the contact plate 51 and the slide plate 23 adjacent to the T-shape, the two wedge-shaped pressing the ipsilateral side of the lower plate 51 away from each other are connected by welding connection plate 52, the connection plate 52 connected to the C-shaped slotted plate 22 between t...

Embodiment 3

[0055] On the basis of Example 2, such as Figure 10 , Figure 11 and Figure 12 Shown, comprises a further anti-slip assembly 6, the anti-slip assembly 6 is provided at the bottom of the support frame 1, the anti-slip assembly 6 for preventing the slide chassis around the cable when the cable is pulled other devices, anti-slip assembly 6 such that the device may application of different widths cable tray, anti-slip assembly 6 comprises a profiled support block 61, the stopper strip 62 is fixed to the expansion frame 63, L-shaped bracket aperture 64, the slide card struts 65, springs 66 and the universal homing ball 67, the bottom of the support frame 1 is connected symmetrically shaped support block 61, a top profiled supporting block 61 fixedly connected with two pairs of stopper strip 62 by welding, on the same side of the stopper strip 62 is opened close to each other a plurality of vertical chutes, the upper stopper strip 62 is connected to the expansion frame 63 is fixed, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com