High-precision lifting hook connecting structure for tower crane

A tower crane and connecting structure technology, applied in the direction of cranes, load hanging elements, cleaning methods and appliances, etc., can solve the problems of inconvenient rotation of lifting ropes, falling of lifting goods, inability to buffer and shock absorption, etc., and achieve convenient nighttime. Work, reduce the impact of heavy objects, high stability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

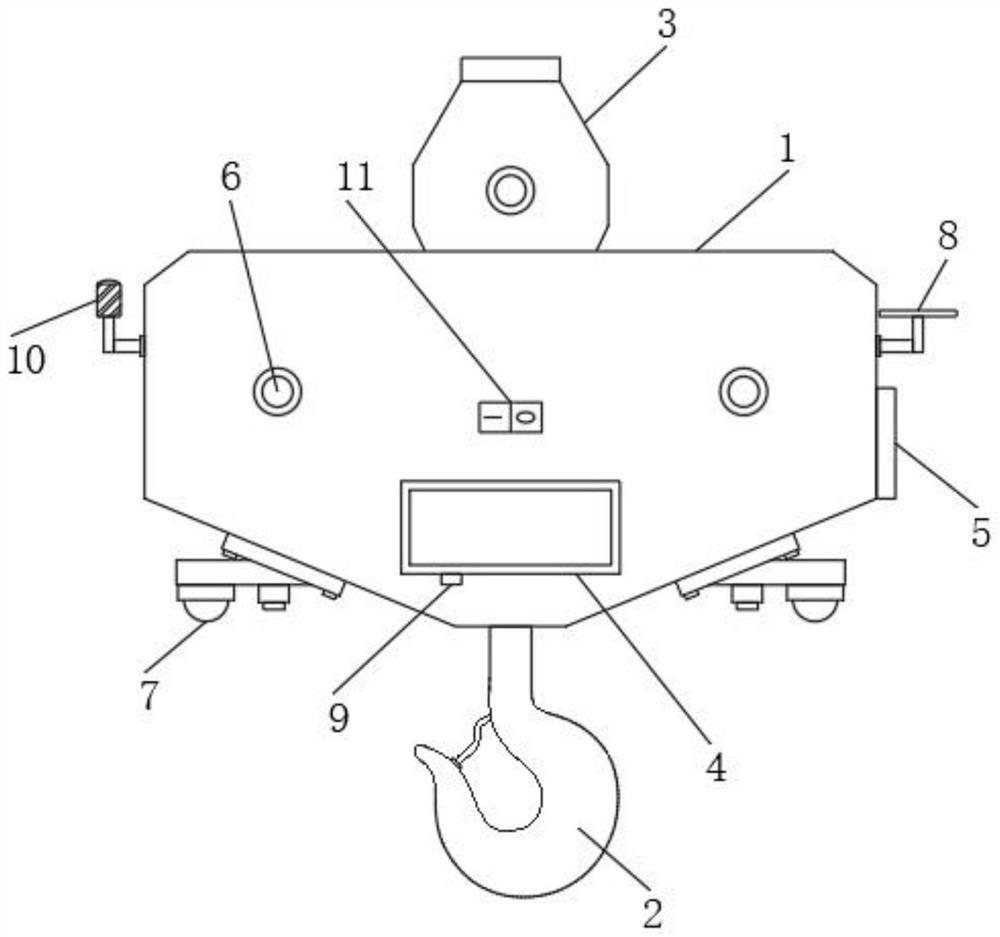

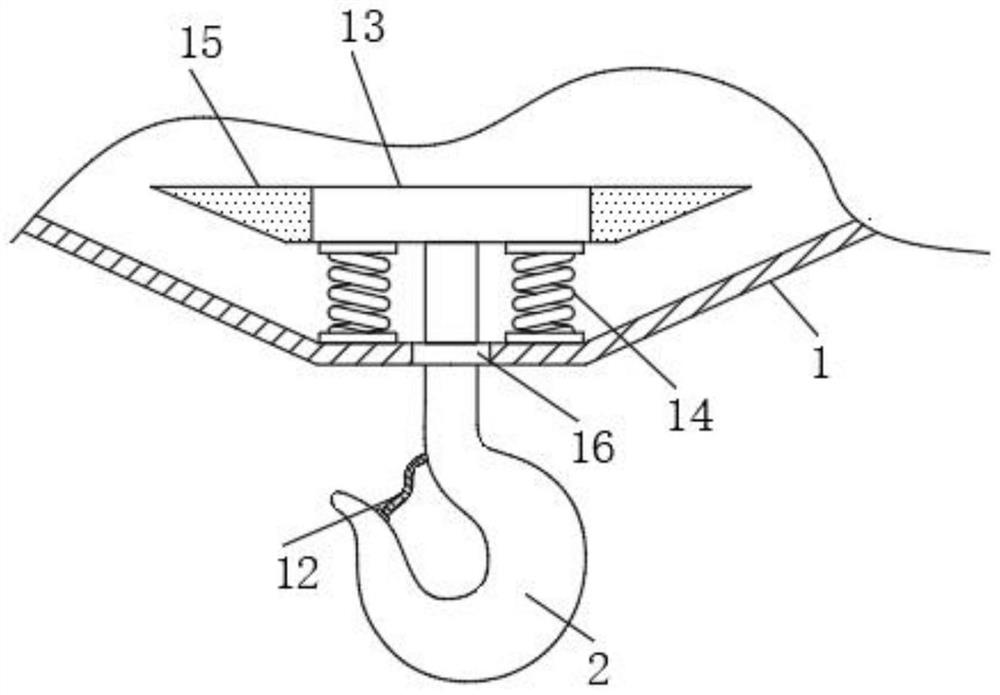

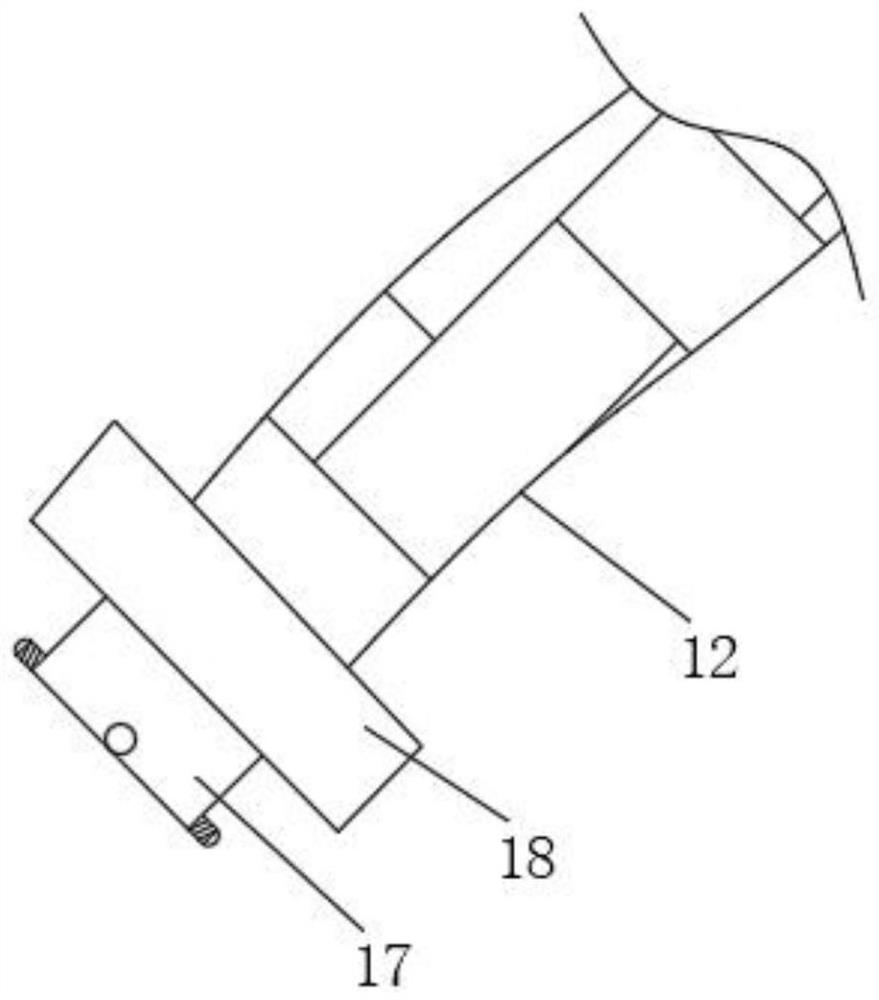

[0036]The embodiment of the present invention provides a technical solution: a high-precision hook connection structure for a tower crane, including a lifting device 1 and a hook 2, the top of the lifting device 1 is provided with an extension wheel 3, and the lifting device The inner two ends of 1 and the middle of the extension suspension wheel 3 are connected with a rotating shaft 6, and the two ends of the bottom of the lifting device 1 are equipped with a horizontal plate 29, and the lower end of the horizontal plate 29 is provided with a monitoring device 7 and an illuminating device 31, The top of the hook 2 runs through the lifting device 1 and is connected with a buffer plate 13, and the two ends of the bottom of the buffer plate 13 are welded with spring columns 14, and the inner end of the hook 2 is connected with a locking rope 12. The lower end of rope 12 is connected with limiting plate 18, and the bottom of described limiting plate 18 is fixedly provided with fix...

example 2

[0038] The embodiment of the present invention provides a technical solution: a high-precision hook connection structure for a tower crane, including a lifting device 1 and a hook 2, the top of the lifting device 1 is provided with an extension wheel 3, and the lifting device The inner two ends of 1 and the middle of the extension suspension wheel 3 are connected with a rotating shaft 6, and the two ends of the bottom of the lifting device 1 are equipped with a horizontal plate 29, and the lower end of the horizontal plate 29 is provided with a monitoring device 7 and an illuminating device 31, The top of the hook 2 runs through the lifting device 1 and is connected with a buffer plate 13, and the two ends of the bottom of the buffer plate 13 are welded with spring columns 14, and the inner end of the hook 2 is connected with a locking rope 12. The lower end of rope 12 is connected with limiting plate 18, and the bottom of described limiting plate 18 is fixedly provided with fi...

example 3

[0040] The embodiment of the present invention provides a technical solution: a high-precision hook connection structure for a tower crane, including a lifting device 1 and a hook 2, the top of the lifting device 1 is provided with an extension wheel 3, and the lifting device The inner two ends of 1 and the middle of the extension suspension wheel 3 are connected with a rotating shaft 6, and the two ends of the bottom of the lifting device 1 are equipped with a horizontal plate 29, and the lower end of the horizontal plate 29 is provided with a monitoring device 7 and an illuminating device 31, The top of the hook 2 runs through the lifting device 1 and is connected with a buffer plate 13, and the two ends of the bottom of the buffer plate 13 are welded with spring columns 14, and the inner end of the hook 2 is connected with a locking rope 12. The lower end of rope 12 is connected with limiting plate 18, and the bottom of described limiting plate 18 is fixedly provided with fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com