Liquid crystal composition containing polymerizable compound and liquid crystal display device

A technology of liquid crystal composition and polymer compound, which is applied in the directions of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of increased difficulty and increase in the manufacturing process of large-size LCD panels, and achieves high practical application value, long and low temperature storage. Effects of time, small surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

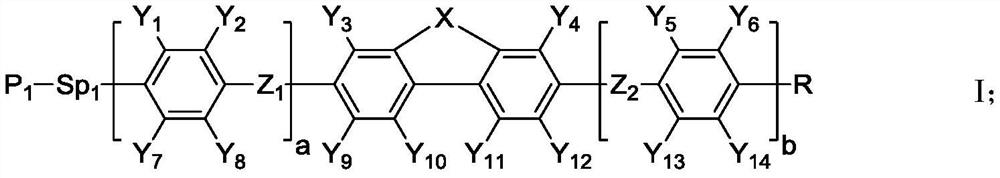

Method used

Image

Examples

Example

[0227] Comparative Examples 1-3 and Examples 1-6

[0228] The liquid crystal composition Host-1 is prepared according to the compounds listed in Table 3 and their weight percentages, as shown in the following table:

[0229] Table 3 The formula and performance parameter test results of the liquid crystal composition Host-1

[0230]

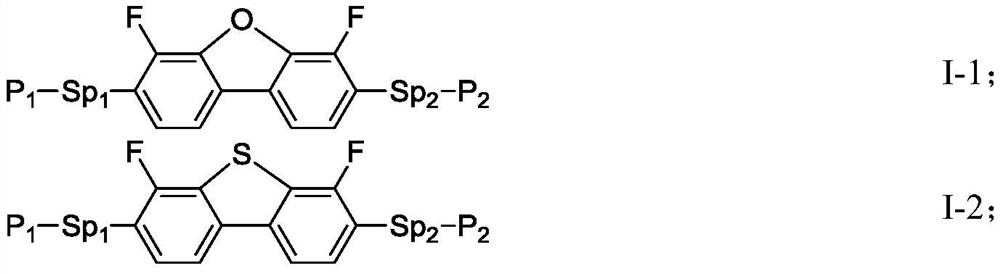

[0231] The polymerizable compounds RM-1, RM-2 and RM-3 were added to 100 parts by weight of the liquid crystal composition Host-1, as comparative examples 1-3, the polymerizable compounds B(O)-1, B(O )-2, B(O)-3 and B(O)-4 were added to 100 parts by weight of the liquid crystal composition Host-1, as Examples 1-6, the specific weight parts of the polymerizable compound and related performance tests The results are shown in Table 4 below:

[0232]

[0233] From the comparison between Comparative Examples 1-3 and Examples 1-6, it can be seen that the surface roughness of the polymer layer of the liquid crystal composition of the present inve...

Example

[0234] Comparative Examples 4-6 and Examples 7-14

[0235] The liquid crystal composition Host-2 is prepared according to the compounds listed in Table 5 and their weight percentages, as shown in the following table:

[0236] Table 5 formula and performance parameter test results of liquid crystal composition Host-2

[0237]

[0238] The polymerizable compounds RM-1, RM-2 and RM-3 were added to 100 parts by weight of the liquid crystal composition Host-2. As comparative examples 4-6, the polymerizable compounds B(O)-1, B(O )-2, B(O)-5, B(O)-6 and B(O)-7 were added to 100 parts by weight of the liquid crystal composition Host-2, as Examples 7-14, the specific Parts by weight and related performance test results are shown in Table 6 below:

[0239]

[0240] From the comparison between Comparative Examples 4-6 and Examples 7-14, it can be seen that the surface roughness of the polymer layer of the liquid crystal composition of the present invention is lower and the unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com