Battery cell, battery cell assembly method and battery

A cell assembly and cell technology, applied in battery cover/end cover, battery pack components, secondary battery manufacturing, etc., can solve problems such as inability to meet fast charging, low overcurrent capacity of tabs, etc., to ensure charging Speed, improve the effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

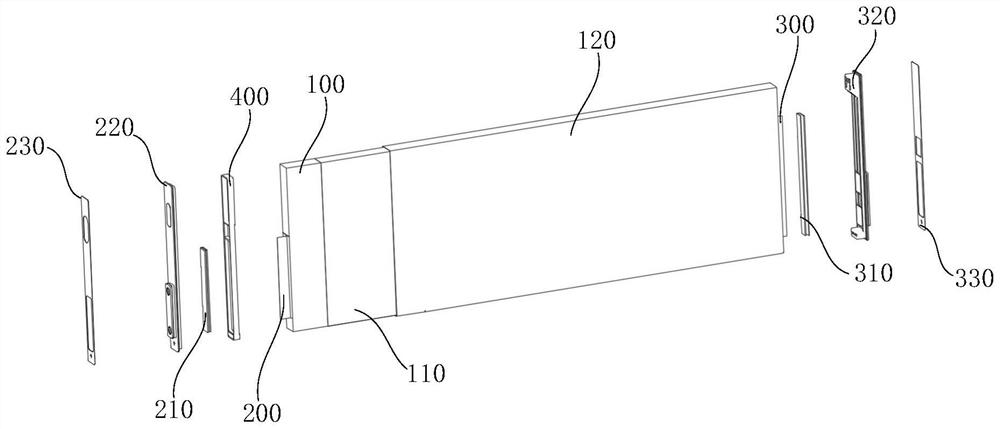

Image

Examples

example 1

[0067] Example 1, the liquid injection part may be disposed on the anode cover plate 220, and the anode top sticker 230 is formed with a gap exposing the liquid injection hole.

example 2

[0068] Example 2, the liquid injection part may be disposed on the cathode cover plate 320, and the cathode top sticker 330 is formed with a gap exposing the liquid injection hole.

example 3

[0069] Example 3, both the anode cover plate 220 and the cathode cover plate 320 are formed with a liquid injection part, similarly, the anode top tab 230 and the cathode top tab 330 may both be formed with a gap exposing the liquid injection hole.

[0070] In addition, similarly, the battery cell can also include an explosion-proof valve, which can be arranged on the anode cover plate 220 and / or the cathode cover plate 320, the anode top sticker 230 and / or the cathode top sticker There are gaps at the positions corresponding to the explosion-proof valves on both sheets 330, and the setting positions of the explosion-proof valves also include three examples, which are similar to the setting of the above-mentioned liquid injection holes and will not be repeated here.

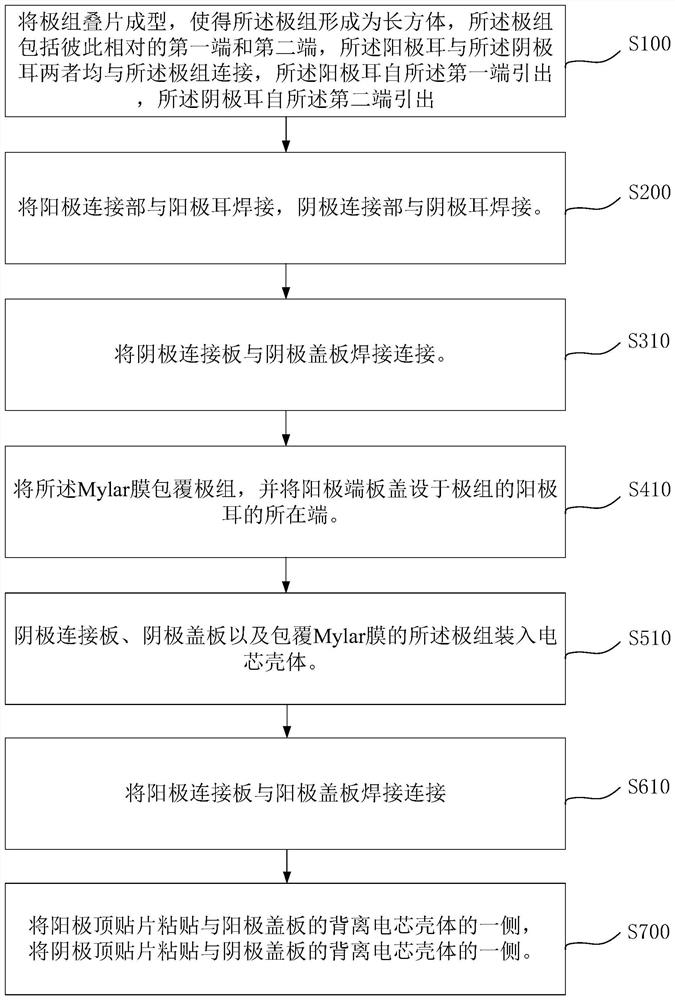

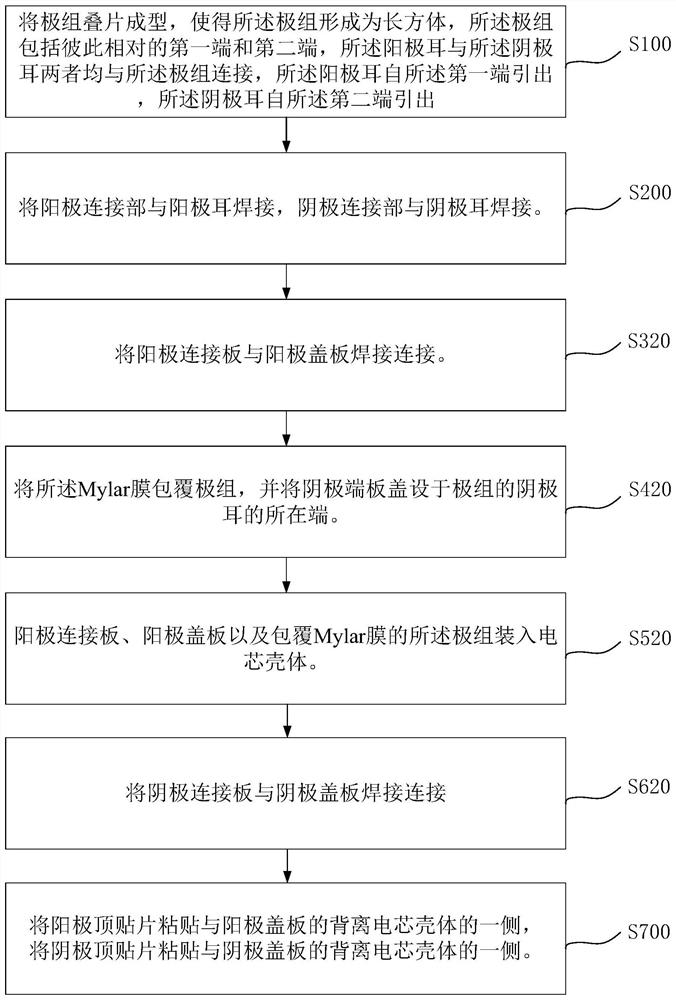

[0071] According to the second aspect of the present application, a battery assembly method is provided, which is used for the assembly of the above-mentioned battery cells, such as figure 2 and image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com