Cistanche deserticola peeling method

A technology of Cistanche and peeling rate, which is applied in the direction of medical formula, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of low peeling rate of Cistanche, large loss of Cistanche, and affecting taste, so as to reduce human participation factors and save The effect of high manpower and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

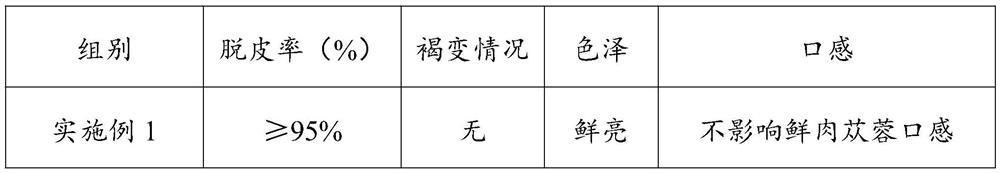

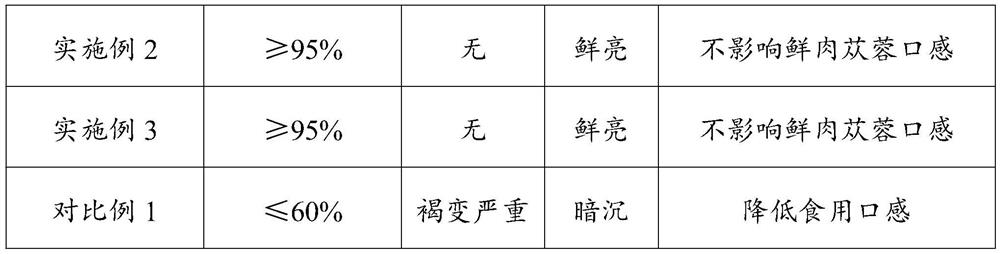

Examples

Embodiment 1

[0021] A method for peeling cistanche, carried out according to the following steps:

[0022] Step 1: First, wash the preferred Cistanche and put it in a ventilated place until there is no water drop on the surface;

[0023] Step 2: Heat the water to 85°C, and add 80g / L salt therein;

[0024] Step 3: Put the cistanche into hot water and blanch for 100 seconds, and remove it after blanching;

[0025] Step 4: Take it out and quickly put it in water at 18°C for 5 minutes;

[0026] Step 5: After taking it out, carry out manual auxiliary treatment, the peeling rate is ≥ 95%, and it can ensure that Cistanche is not damaged;

Embodiment 2

[0028] A method for peeling cistanche, carried out according to the following steps:

[0029] Step 1: First, wash the preferred Cistanche and put it in a ventilated place until there is no water drop on the surface;

[0030] Step 2: Heat the water to 90°C, and add 65g / L salt therein;

[0031] Step 3: Put the cistanche into hot water and blanch for 95 seconds, and remove it after blanching;

[0032] Step 4: Take it out and quickly put it in water at 20°C for 7 minutes;

[0033] Step 5: After taking it out, carry out manual auxiliary treatment, the peeling rate is ≥ 95%, and it can ensure that Cistanche is not damaged;

Embodiment 3

[0035] A method for peeling cistanche, carried out according to the following steps:

[0036] Step 1: First, wash the preferred Cistanche and put it in a ventilated place until there is no water drop on the surface;

[0037] Step 2: Heat the water to 95°C, and add 50g / L salt therein;

[0038] Step 3: Put Cistanche deserticola in hot water for 90 seconds, and remove it after blanching;

[0039] Step 4: Take it out and quickly put it in water at 25°C for 8 minutes;

[0040] Step 5: Carry out manual auxiliary treatment after taking out, the peeling rate is ≥ 95%, and it can ensure that Cistanche deserticola is not damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com