Flue gas exhaust system

A smoke exhaust system and flue gas technology, applied in gas treatment, dispersed particle filtration, transportation and packaging, etc., can solve the problems of harmful gas, high cost, unstable effect, etc., and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

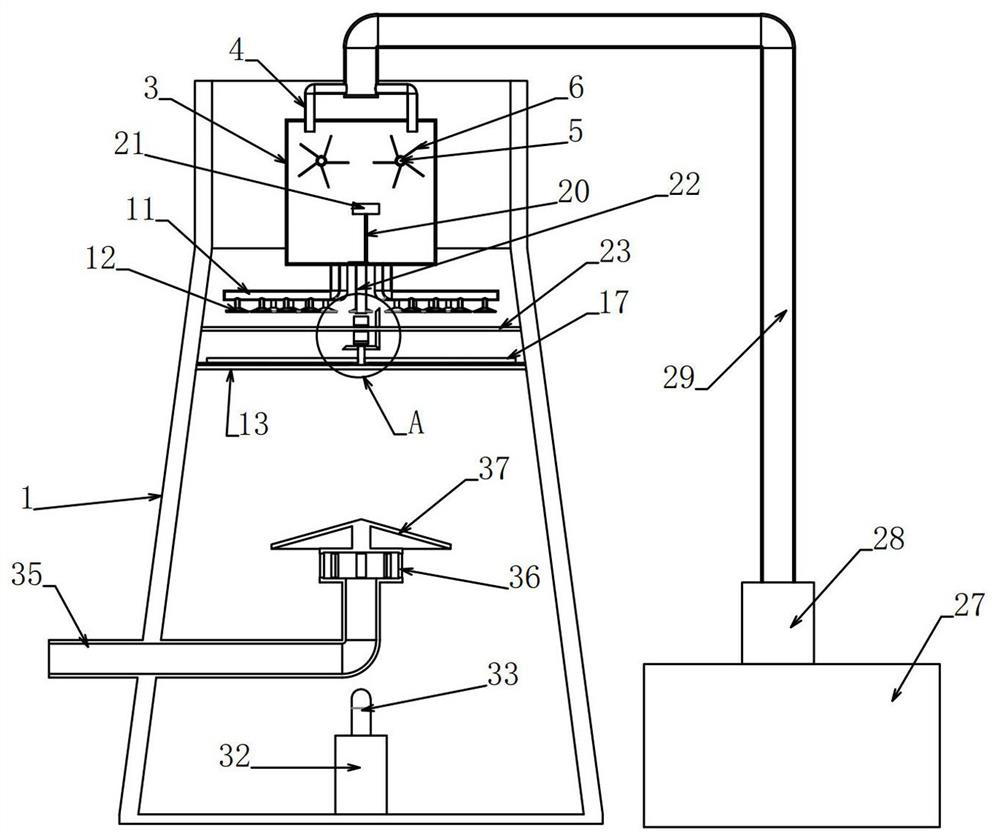

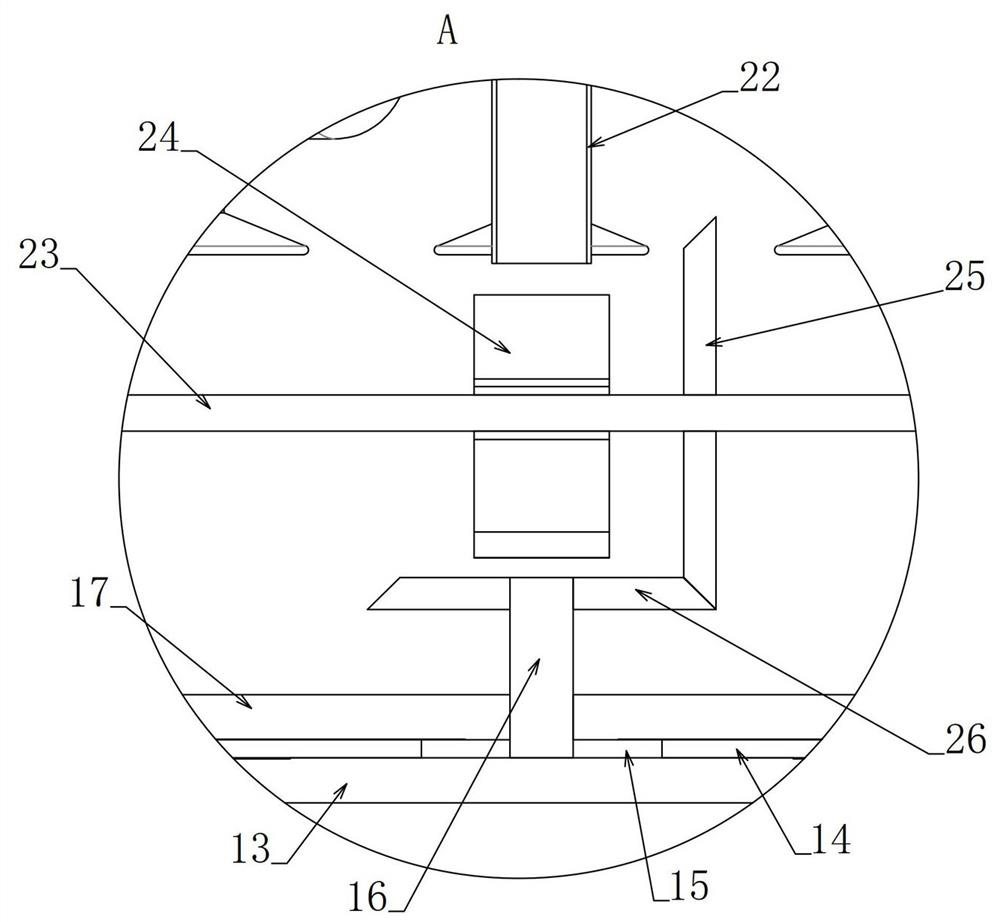

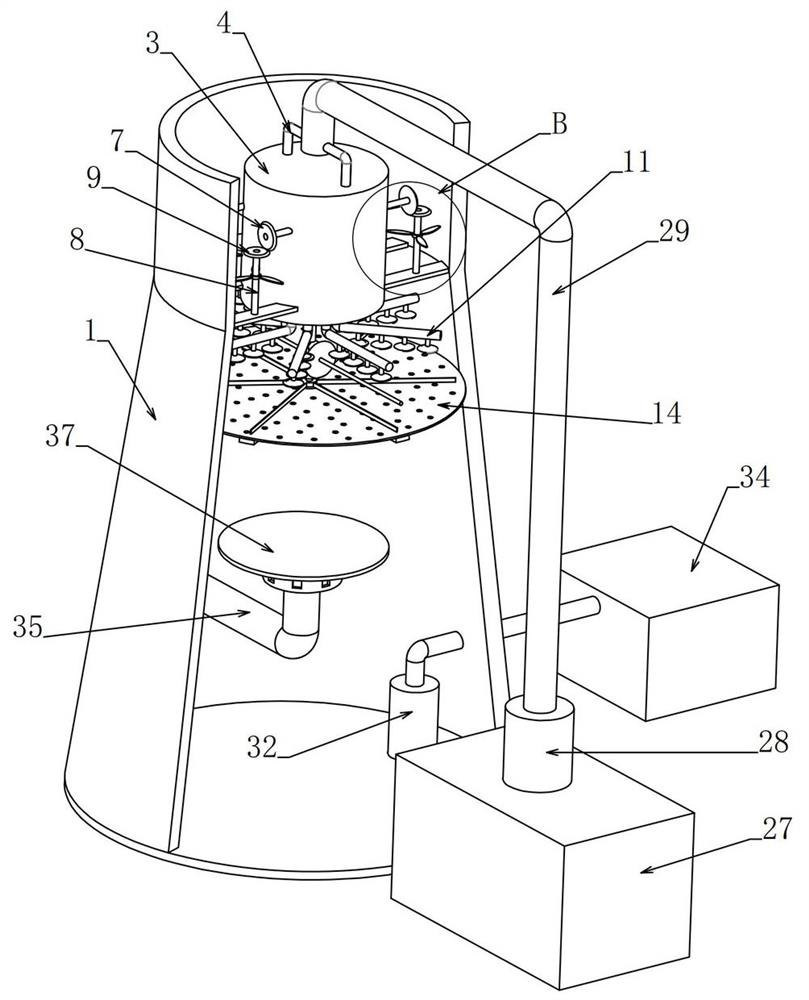

[0027] The following is attached Figure 1-9 The specific implementation manners of the present invention are further described in detail.

[0028] The provided liquid supply device can pump the lye in the lye tank 27 to the conduit 4 through the metering pump 28, and the lye enters the water tank 3 through the conduit 4 and sprays out from the shower head 12 of the spraying device. The lye sprayed by the shower head 12 reacts with nitrogen oxides, sulfur oxides and carbon dioxide in the flue gas to remove harmful gases in the flue gas; the lye is discharged from the outlet end of the conduit 4 and falls onto the upper water wheel 6 to thereby The upper water wheel 6 drives the rotating shaft 5 to rotate, and the first bevel gear 7 on the rotating shaft 5 will drive the induced fan 10 on the vertical shaft 8 to rotate through the cooperation with the second bevel gear 9, and the induced fan 10 will attract the processed smoke. The flue gas is discharged to the outside of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap