Tool equipment for hard shell type machine body

A kind of tooling equipment, hard-shell technology, applied in the direction of workpiece clamping device, manufacturing tools, weight reduction, etc., can solve the problems of low assembly efficiency and high requirements for assembly personnel, and achieve the goal of improving assembly efficiency, improving assembly quality, and reducing requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

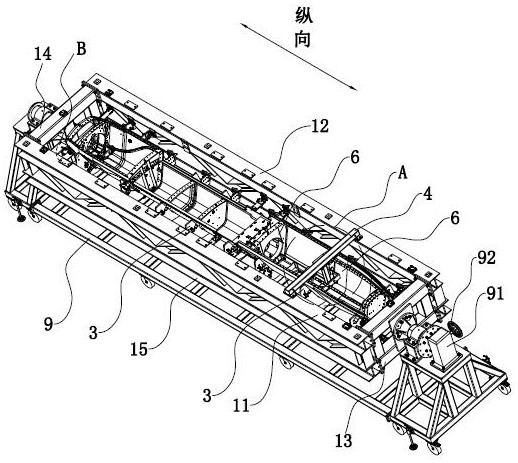

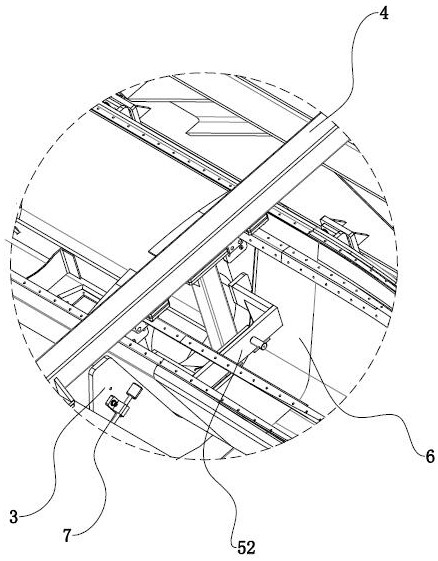

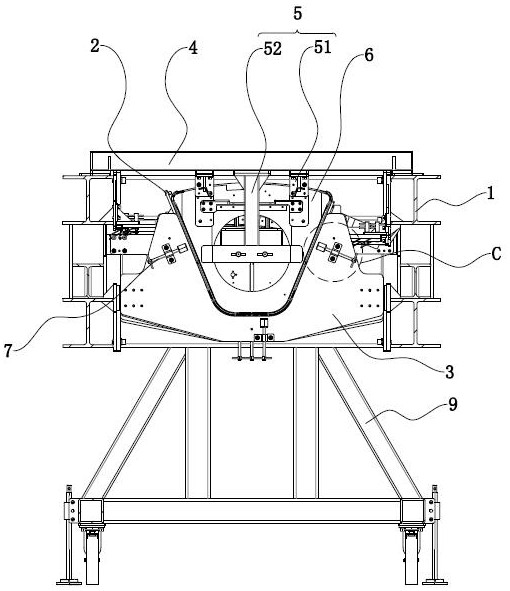

[0034] The following combination Figure 1 to Figure 6 The present invention is described in further detail.

[0035] The embodiment of the invention discloses a tooling device of a hard-shell fuselage. refer to figure 1 , a tooling device for a monocoque fuselage includes a receiving frame 1 , a supporting partition 3 , a beam 4 and a frame positioner 5 . The top of the receiving frame 1 is open, and can accommodate the lower fuselage 2 of the monocoque fuselage. The number of support partitions 3 is multiple, and the plurality of support partitions 3 are arranged in the storage frame 1 at intervals along the longitudinal direction of the storage frame 1 (that is, the front and rear directions), and each support partition 3 has an accommodation gap, This enables each support partition 3 to accommodate and position the lower fuselage 2 through its respective accommodation opening. The crossbeam 4 is arranged above the receiving frame 1, so that the bulkhead positioner 5 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com