Large-span prestressed concrete beam formwork structure

A concrete beam and prestressing technology, applied in building construction, formwork/formwork/work frame, on-site preparation of building components, etc. The effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-5 The application is described in further detail.

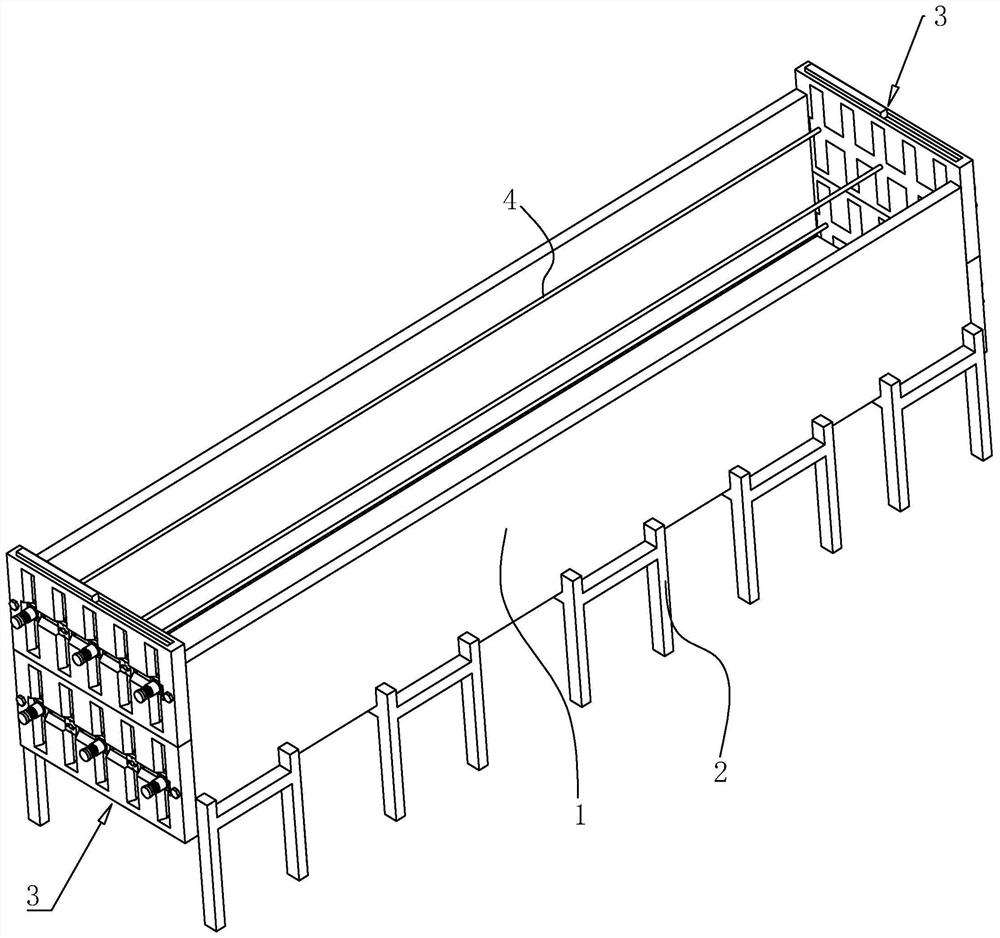

[0039] The embodiment of the present application discloses a large-span prestressed concrete beam support formwork structure. refer to figure 1 A long-span prestressed concrete beam formwork structure includes a beam formwork 1, a support structure 2 at the bottom of the beam formwork 1, and fixing members 3 at both ends of the beam formwork 1.

[0040] refer to figure 1 The beam formwork 1 is composed of three steel formworks fixed and spliced by bolts. The cross section of the beam formwork 1 perpendicular to the length direction is U-shaped, and the supporting structure 2 is a supporting scaffold formed by overlapping steel pipes.

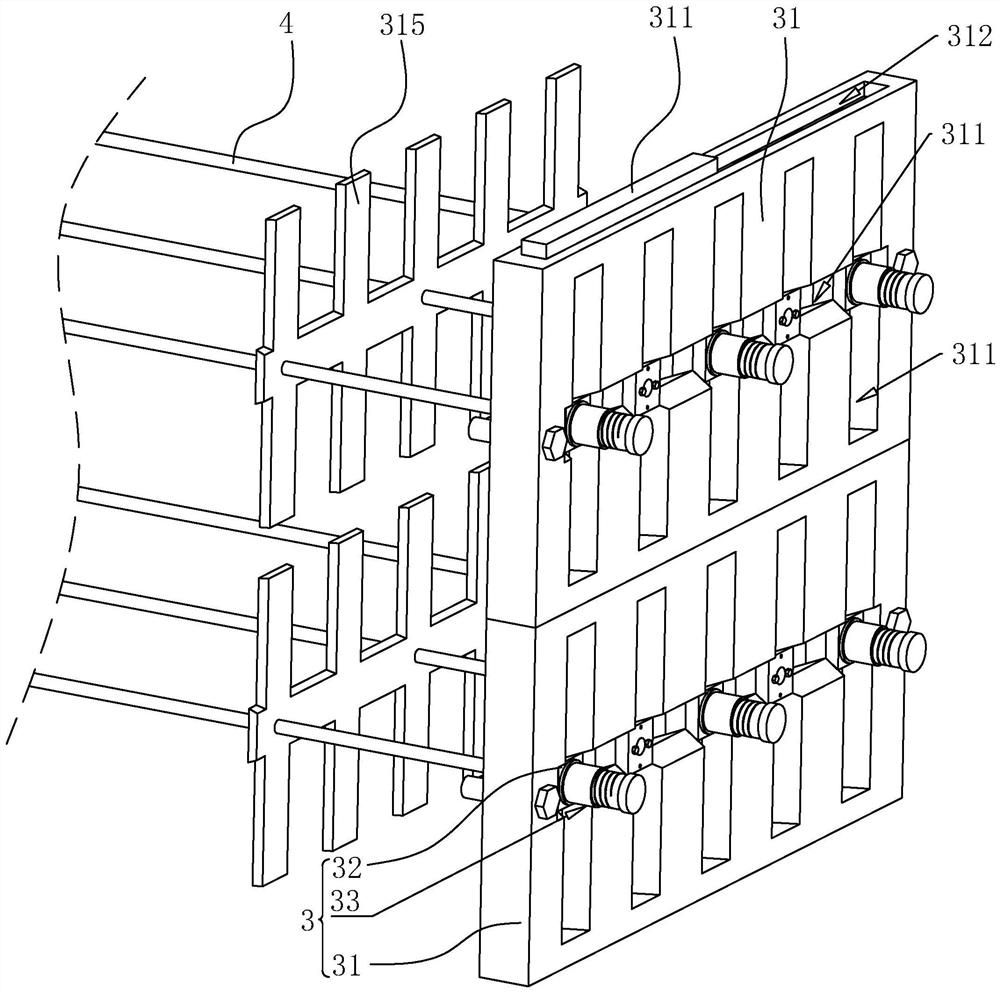

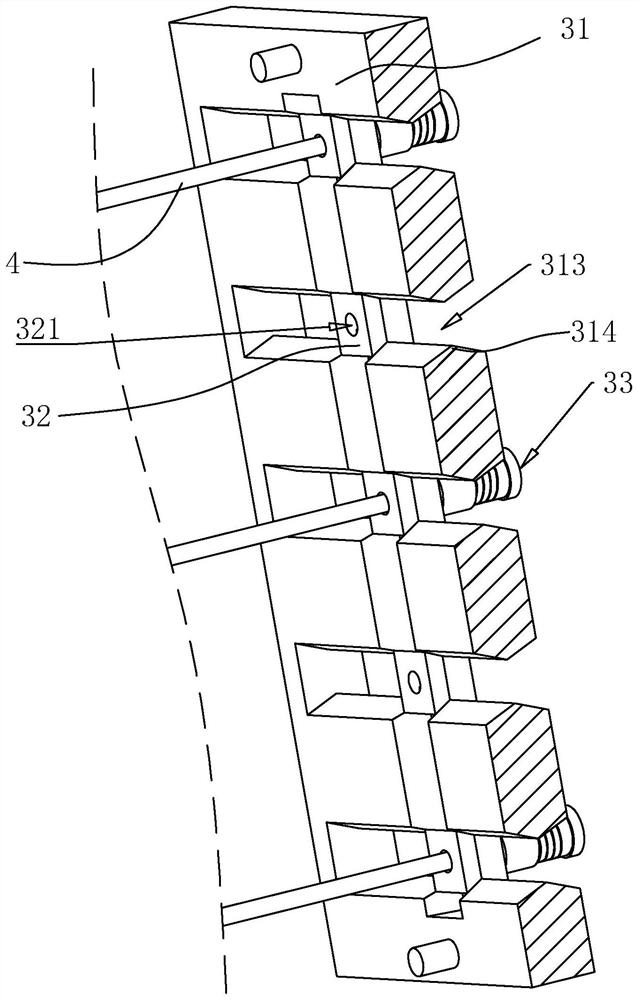

[0041] refer to figure 1 and figure 2 The fixed member 3 includes a base plate 31, a positioning block 32 and a tension member 33. There are multiple base plates 31, and two opposite side walls of the base plate 31 along the thickness direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com