Electric control automatic gear shifting system for hydraulic drive agricultural machinery

A technology for agricultural machinery and automatic gear shifting, applied in transmission control, mechanical equipment, transmission, etc., can solve problems such as affecting driving comfort, poor cab sealing, occupying cab space, etc., to improve production efficiency and economy. benefits, solving sealing problems, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

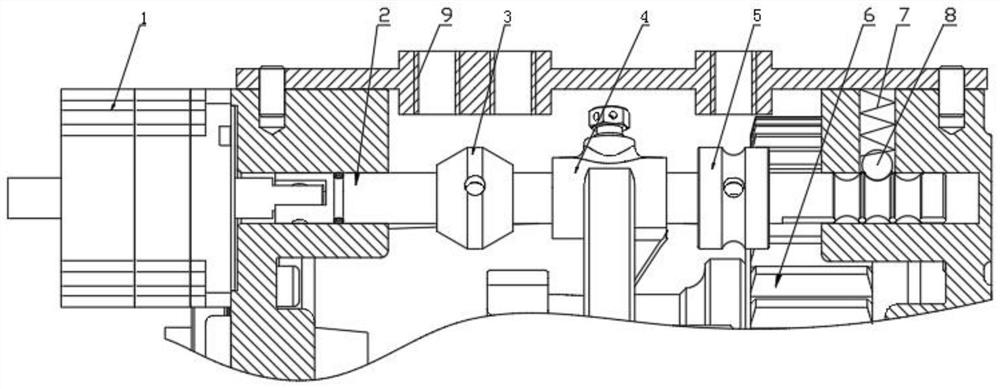

[0029] An electrically controlled automatic shifting system for hydraulically driven agricultural machinery such as figure 1 As shown, its structure includes a telescopic stepper motor 1 as a power source, the telescopic stepper motor 1 is fixed on the gearbox casing, the output shaft of the telescopic stepper motor 1 extends horizontally to the inside of the gearbox casing, and the telescopic stepper motor 1 The output shaft of 1 is connected with one end of the shaft 2, and the other end of the shaft 2 is connected with the guiding and limiting structure. When the output shaft of the telescopic stepping motor 1 is stretched out, the shaft 2 is driven to move to the right synchronously, and when the output shaft of the telescopic stepping motor 1 is withdrawn, the shaft 2 is driven to move to the left synchronously.

[0030] Specifically, the structure of the guiding and limiting structure includes a block fixed to the inside of the gearbox housing. A guiding hole is opened o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com