Energy coupling device for gas-carbon generator in activated carbon production

A technology for activated carbon production and coupling devices, which is applied in the direction of climate sustainability, biofuels, and the manufacture of combustible gases. Production efficiency and economic benefits, the effect of improving the screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

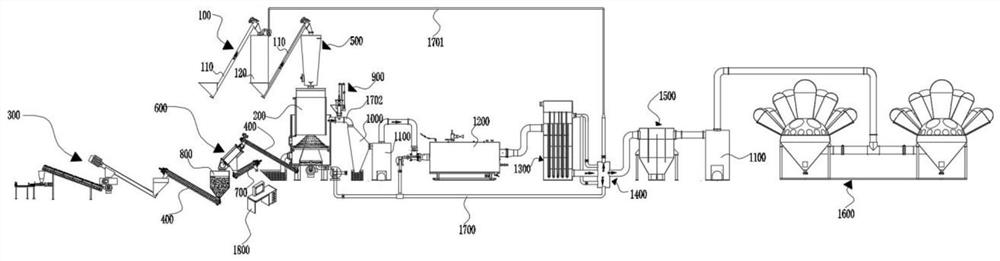

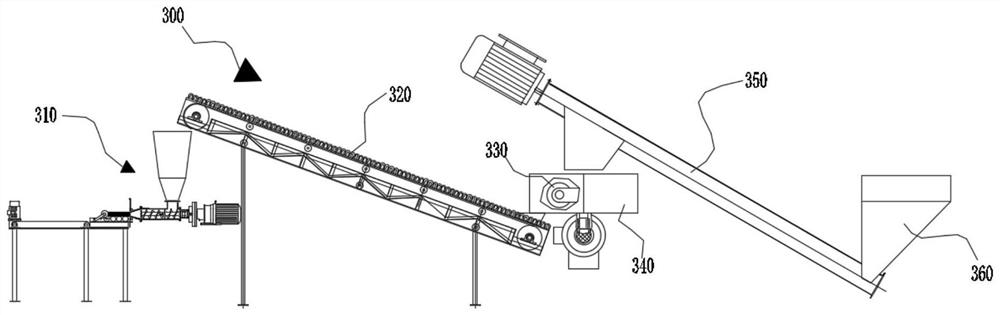

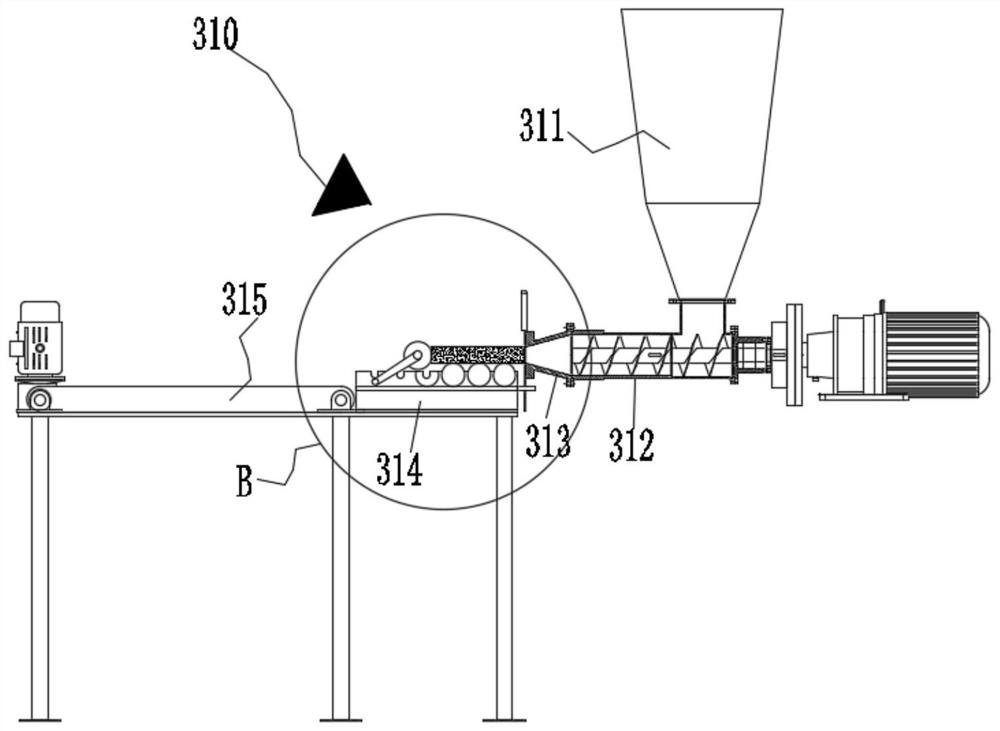

[0053] see figure 1 , the present embodiment, a gas-charcoal generator and an energy coupling device for activated carbon production, including feeding equipment 100, biomass charcoal forming equipment 300, side-suction gasifier 200, boiler 1200, combustion-supporting equipment, and primary dust removal equipment , secondary dedusting equipment, and DCS electric control cabinet 1800, the feeding equipment 100 is connected to the side suction gasifier 200, and then the biomass fuel (such as agricultural and forestry crop straw, new firewood scraps, shale sludge, etc.) Carry out sealed feeding into the side-suction gasifier 200; the biomass fuel undergoes high-temperature oxidation-reduction reaction in the side-suction gasifier 200 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com