HF fireproof heat-insulating board and manufacturing method thereof

A fireproof insulation board and manufacturing process technology, applied in the direction of manufacturing tools, ceramic products, and other household appliances, can solve the problems of poor environmental performance and poor fireproof performance of organic insulation boards, and achieve firm structure, excellent heat preservation effect, and improved product quality. Effects of mass and load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

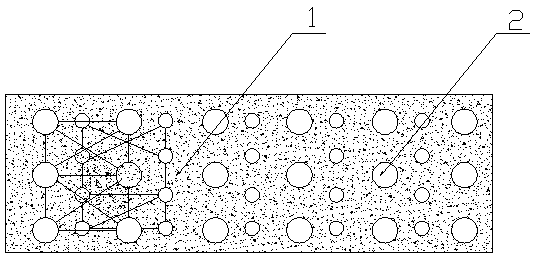

[0018] Such as Figure 1-2 As shown, the present invention provides an HF fireproof insulation board and its manufacturing process. It includes an inorganic cement layer 1, polystyrene particles 2. The inorganic cement layer 1 is a rectangular plate structure, and the inorganic cement layer 1 is uniform Several polystyrene particles 2 are distributed. The sides of several polystyrene particles 2 are connected to each other to form a molecularly connected organization structure. Several polystyrene particles 2 separate the inner cavity of the inorganic gel layer 1 to form a honeycomb Cavity structure.

[0019] As the manufacturing process of a HF fireproof insulation board of the present invention, the inorganic gel layer 1 is made of silicon powder, calcium carbonate, bentonite, kaolin, fly ash, short fibers, water repellent and foaming agent. According to different fire insulation grades, it can be flexibly prepared in proportion.

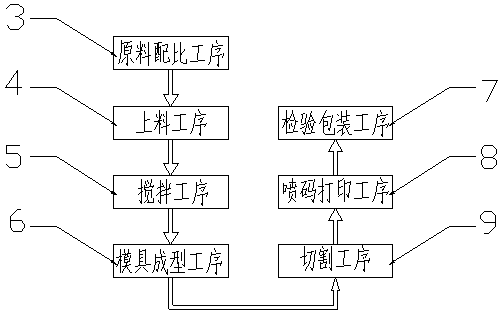

[0020] Further, the mixing production process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com