Method and equipment for combined production of oil and bricks by using oil shales

A technology of oil shale and equipment, which is applied in the field of oil shale oil brick co-production method and equipment, can solve the problems of no oxygen isolation measures, explosion, fire production accidents, unfavorable continuous mass production, etc., so as to improve economic benefits and production efficiency, emission reduction, and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

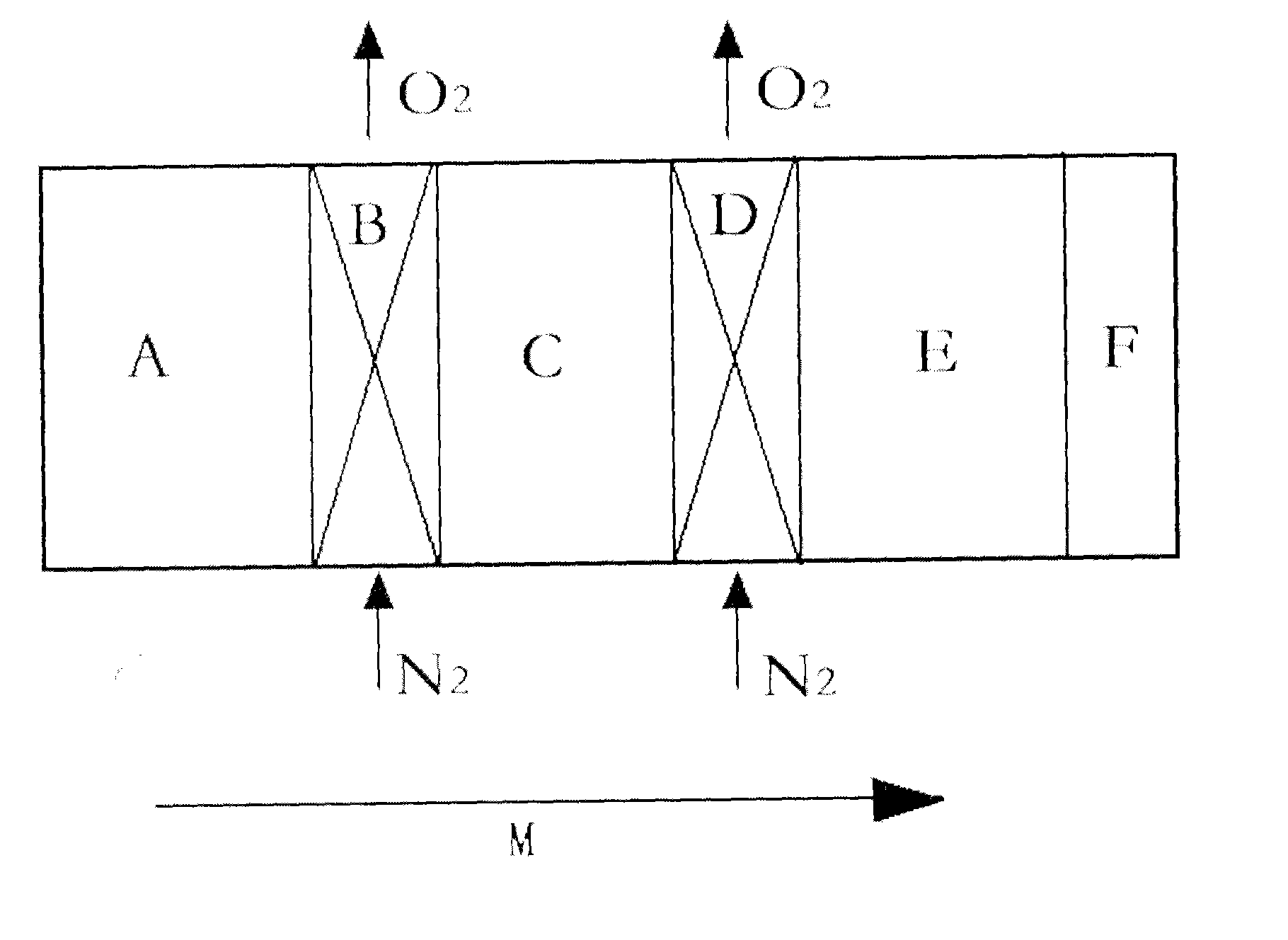

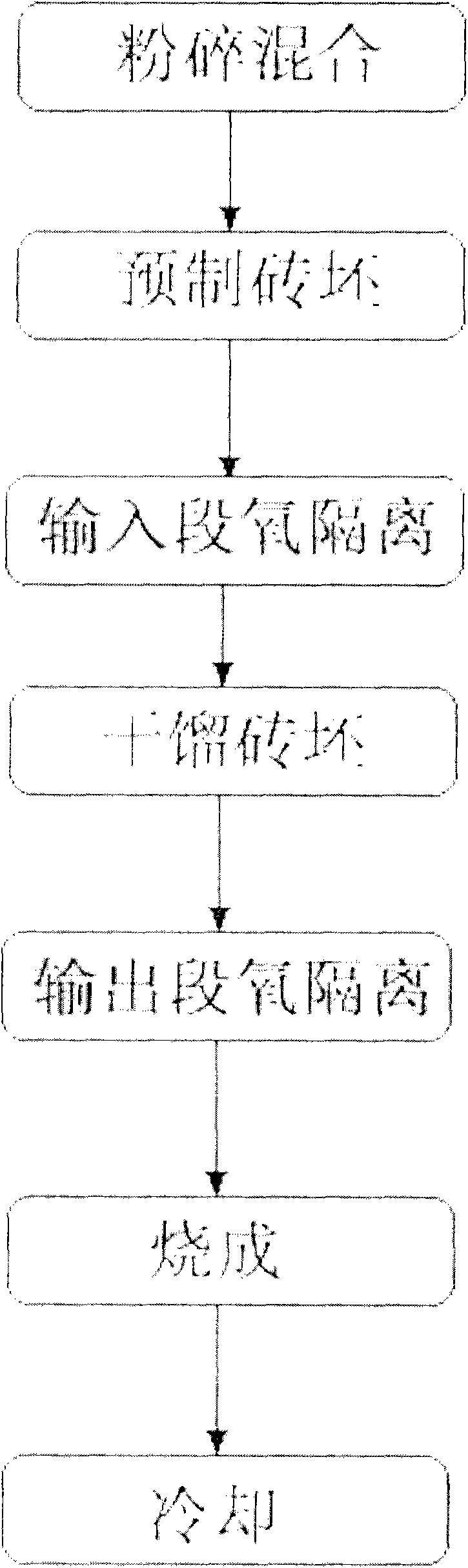

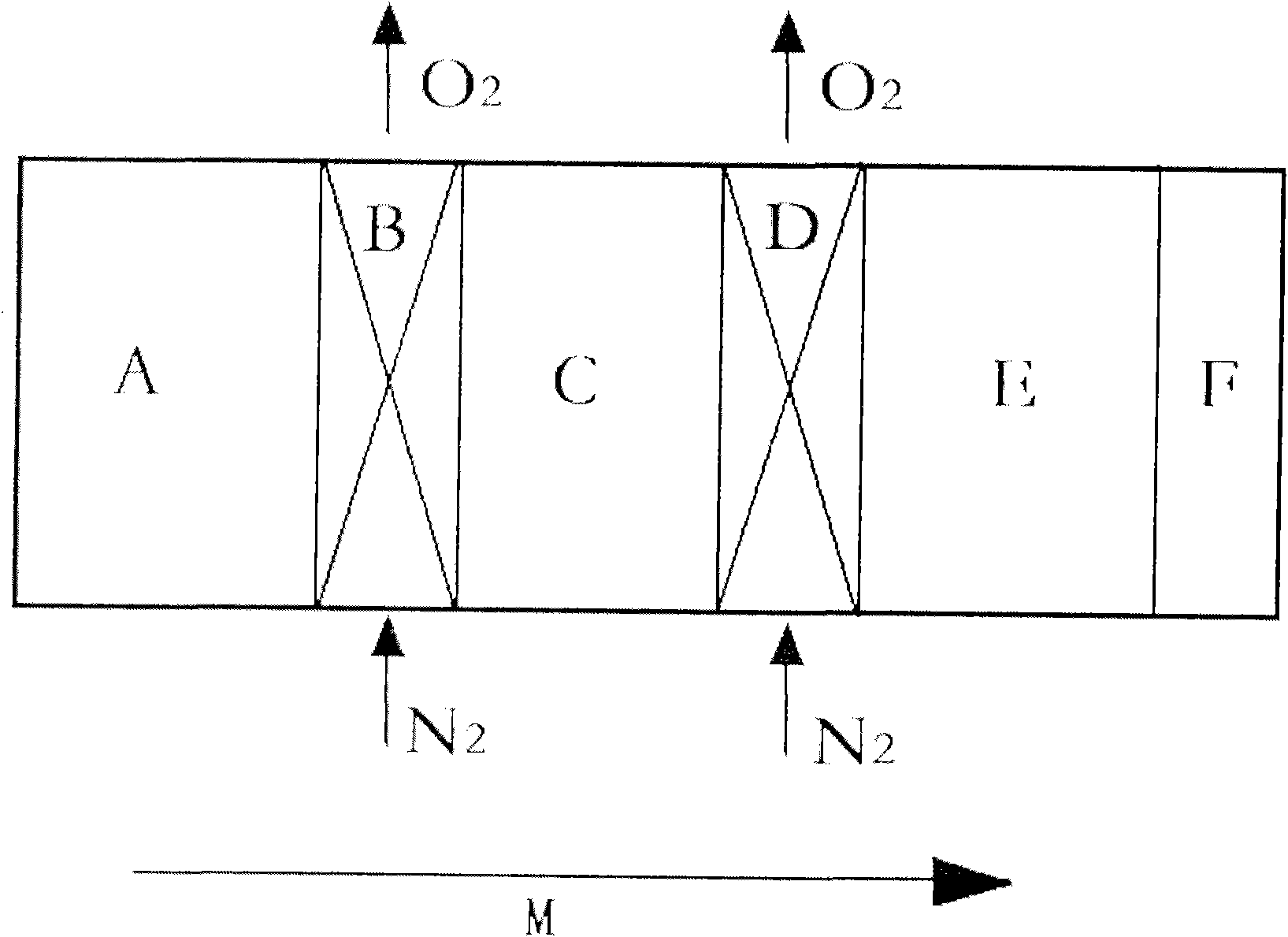

[0042] Figure 1 is a flow chart of the method of the present invention. Fig. 2 is a tunnel kiln in the oil shale oil brick co-production equipment for implementing the method of the present invention. Oil shale oil brick co-production equipment includes a pulverizing and mixing unit, a prefabricated brick unit and a tunnel kiln, wherein the pulverizing and mixing unit and the prefabricated brick unit are arranged upstream of the tunnel kiln, wherein the prefabricated brick unit is preferably directly connected with the preheating section A of the tunnel kiln adjacent. The tunnel kiln mainly includes a preheating section A, an input section oxygen isolation room B, a dry distillation section C, an output section oxygen isolation room D, a firing section E and a cooling section F. The preheating section A can adopt common preheating methods in various prior art in the brick making process. The oxygen isolation room B in the input section has an input gate, an output gate, an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com