Gas valve

A valve and gas technology, applied in the direction of valve details, valve devices, multi-way valves, etc., can solve the problems that cannot meet the requirements of high and medium pressure gas use, extremely high requirements for processing machine tools, and insufficient service life, etc., to achieve superior sealing performance, Good sealing and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

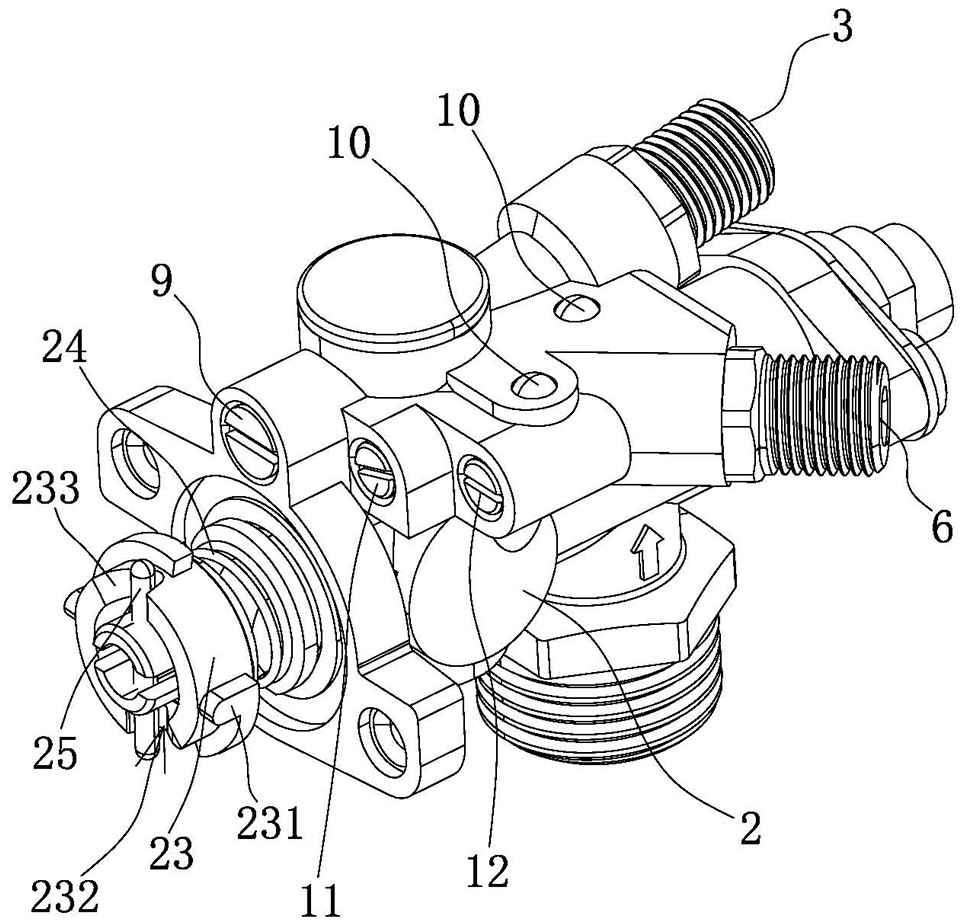

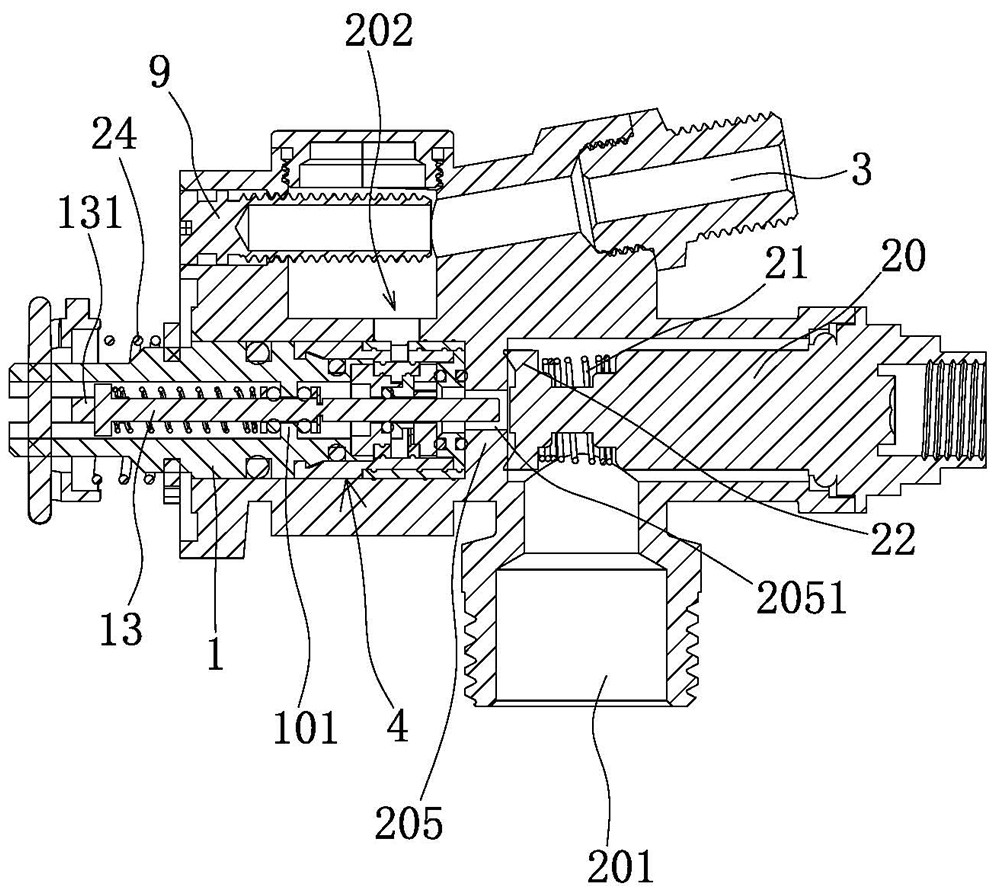

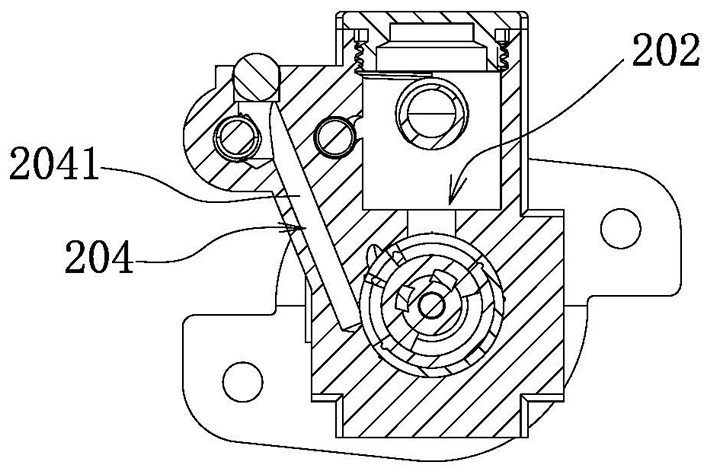

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9As shown, the gas valve includes a valve stem 1 and a valve body 2. There is a valve cavity in the valve body 2. The valve body 2 has an inlet port 201 and a large and small fire outlet port 3 that are all communicated with the valve cavity. The valve core 4, the outer wall of the valve stem 1 is fitted with a sealing ring 5 that is sealed on the inner wall of the valve cavity. There are large fire holes 411, small fire holes 412 and permanent flame holes 413 that penetrate radially and are all in the shape of arc grooves. Larger than the gas passing area of the small fire hole 412, the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com