Bio-boiler large dust automatic cleaning heat recovery equipment

An automatic cleaning and heat recovery technology, which is applied in lighting and heating equipment, combustion equipment, solid fuel pretreatment, etc., can solve the problems of heat recovery, waste, and heat loss of flue gas that cannot be used at high temperatures, and avoid excessive moisture in fuel. More, full combustion, high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

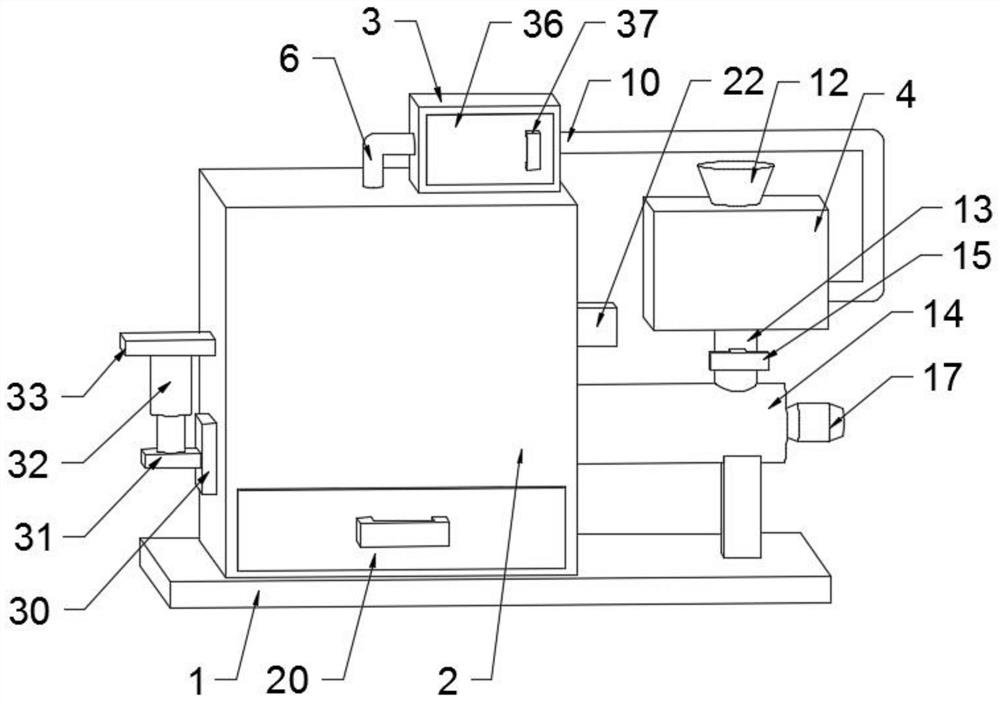

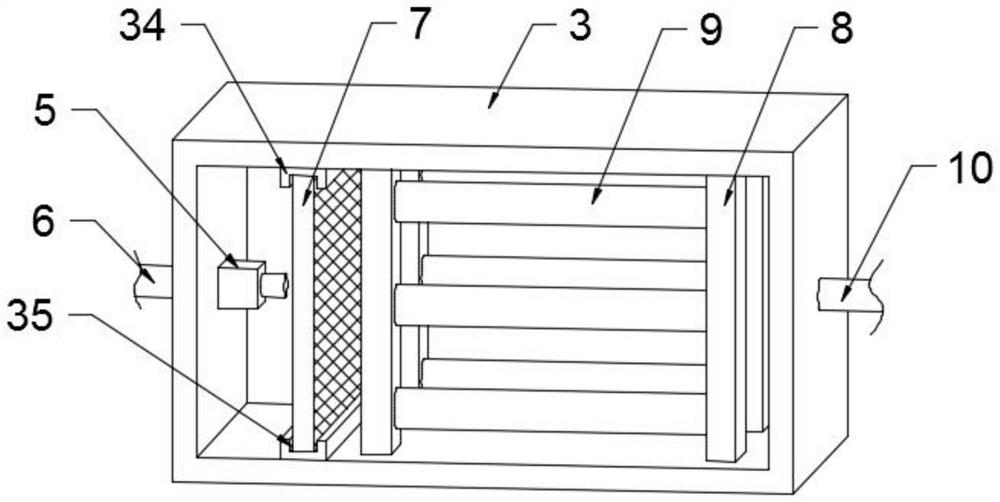

[0028] see Figure 1-Figure 5 , in the embodiment of the present invention, the bio-boiler large dust automatic cleaning heat recovery equipment includes a base 1, which is used to support and place the boiler body 2, and the boiler body 2 fixedly connected to the upper end of the base 1 is used to support and fix the filter box 3, which is fixedly connected The filter box 3 at the upper end of the boiler body 2 is used to support and place the filter screen 7 and the dust bag 9, and the discharge box 4 fixedly arranged on the right side of the boiler body 2 is used to store fuel and also includes a recovery component;

[0029] The recovery assembly is used to recover the heat in the exhaust gas generated inside the boiler body 2, the recovery assembly is fixedly arranged between the filter box 3 and the discharge box 4, the recovery assembly includes an aspirator 5, and the suction The suction machine 5 is fixedly installed on the left inner wall of the filter box 3, and is u...

Embodiment 2

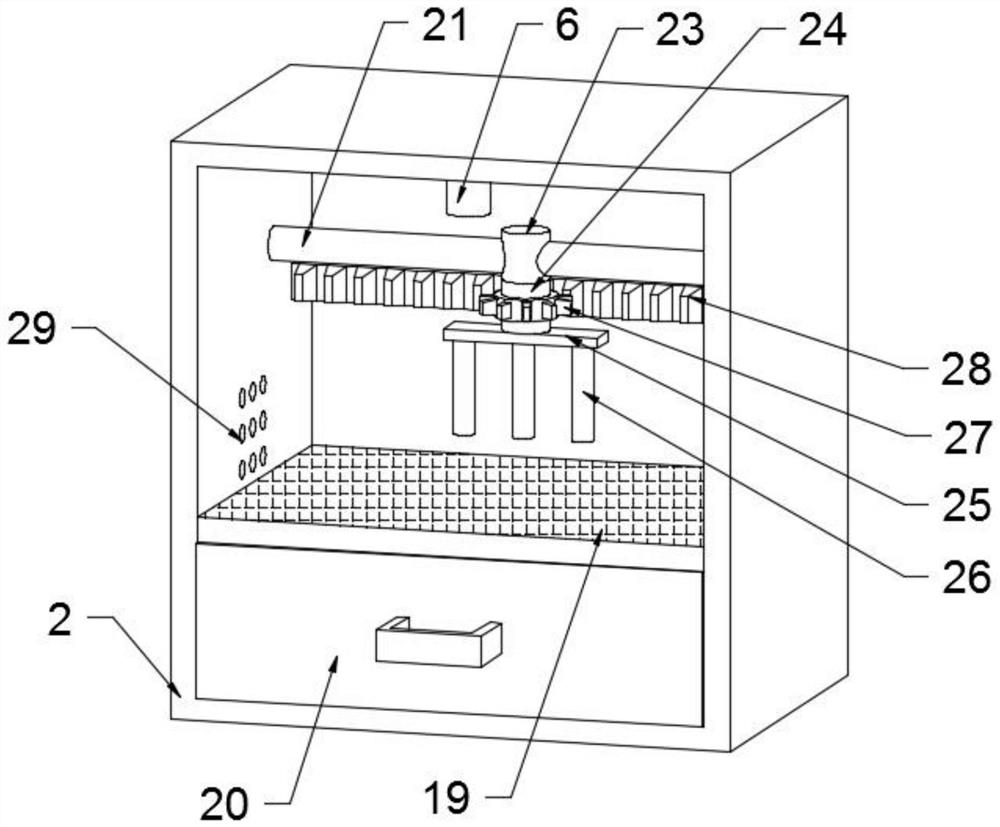

[0038] The difference from Embodiment 1 is that: the inner walls of the left and right sides of the boiler body 2 are rotatably connected with reciprocating screw rods 21, which are used to drive the screw rod sleeves 23 to move left and right. The output end of the reciprocating screw rod 21 is fixedly connected, and the rotating motor 22 is fixedly installed on the right side outer wall of the boiler body 2 to drive the reciprocating screw rod 21 to rotate. The outer fixed sleeve of the reciprocating screw rod 21 is provided with a screw rod cover 23 for use To drive the rotating rod 24 to move left and right, the lower end of the screw mandrel cover 23 is rotatably connected with a rotating rod 24, which is used to drive the fixed plate 25 to move left and right, and the lower end of the rotating rod 24 is fixedly connected with a fixed plate 25, which is used to drive the stirring The rod 26 moves left and right, and the lower end of the fixed plate 25 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com