A double-adjustable high-efficiency garbage disposal system

A treatment system and double-adjustment technology, applied in the direction of combustion type, combustion method, lighting and heating equipment, etc., can solve the problems that it is difficult to ensure the balance of temperature and affect the uniformity of waste treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the technical solution of the present invention will be described in detail through specific examples.

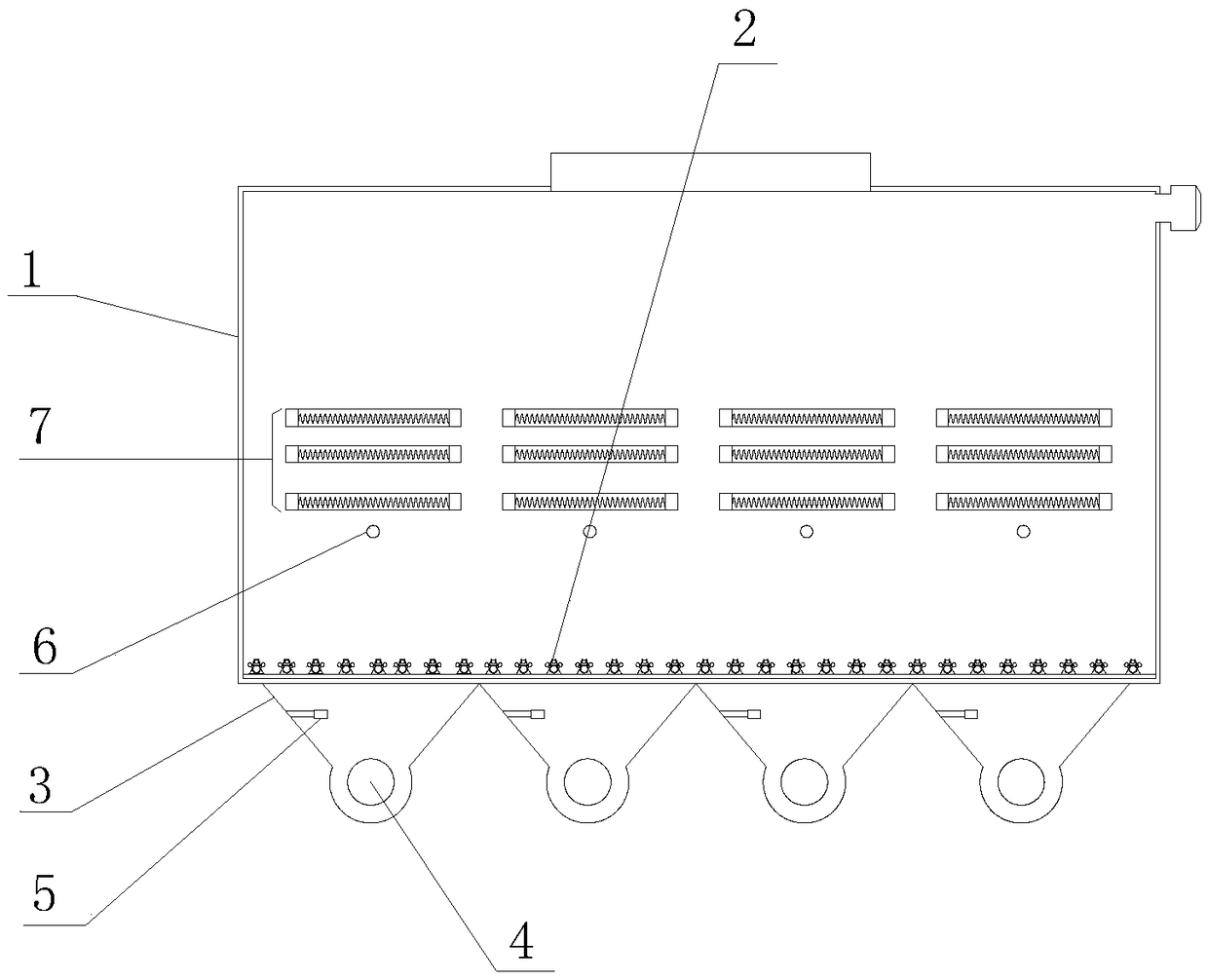

[0028] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a dual-adjustment high-efficiency garbage treatment system proposed by the present invention.

[0029] refer to figure 1 , a dual-adjustment high-efficiency garbage treatment system proposed in the embodiment of the present invention, comprising: a furnace body 1, a blast device (not shown in the figure) and a control device (not shown in the figure), wherein:

[0030] The top of the body of furnace 1 is provided with a feeding port, and the feeding port is provided with an end cover for sealing the feeding port; in the body of furnace 1 and on the side near its bottom, an air supply pipe row 2 is laid, and the air supply The pipe row layer 2 is formed by a number of air supply pipes with air distribution holes arranged at equal intervals in sequence, and along the arrangemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com