Test assembly capable of avoiding thermal influence in linear welding spot electromigration process and manufacturing method thereof

A technology for testing components and linear welding, which is applied in the direction of electronic circuit testing, test sample preparation, and electrical measurement, which can solve problems such as uneven thermal stress and melting of solder joints, and achieve the effect of reducing experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The first embodiment is described by taking the production of a Cu / Sn3.0Ag0.5Cu / Cu butt single crystal joint with uniform grain orientation, a cross-sectional size of 300 μm×300 μm, and a weld width of 300 μm as an example.

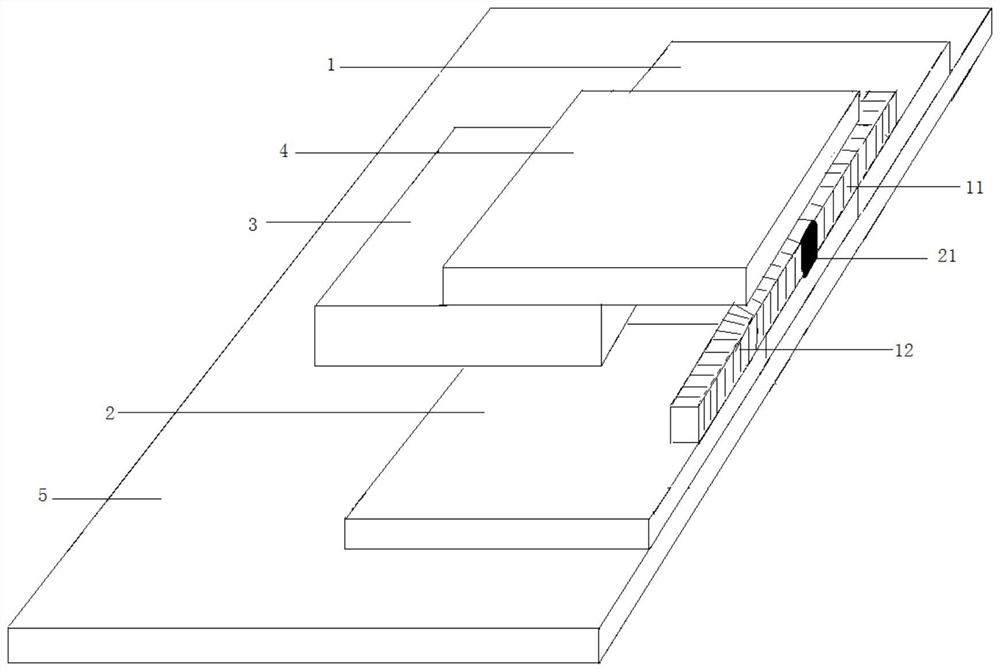

[0034] Such as figure 1 As shown, the test assembly for avoiding the thermal influence of the linear solder joint electromigration process according to the embodiment of the present application is characterized in that it includes a linear butt welding copper rod, a base plate 5 and a structural plate. Wherein, the linear butt welding copper rod comprises a linear welding point 21, a first copper rod 11 and a second copper rod 12; It is welded and connected with the second copper rod 12; the structural plate wraps the linear butt welding copper rod, the cross section of the linear butt welding copper rod is rectangular, and only one side of the linear butt welding copper rod is visible; the base plate 5 is used to carry the structural plate.

[00...

Embodiment 2

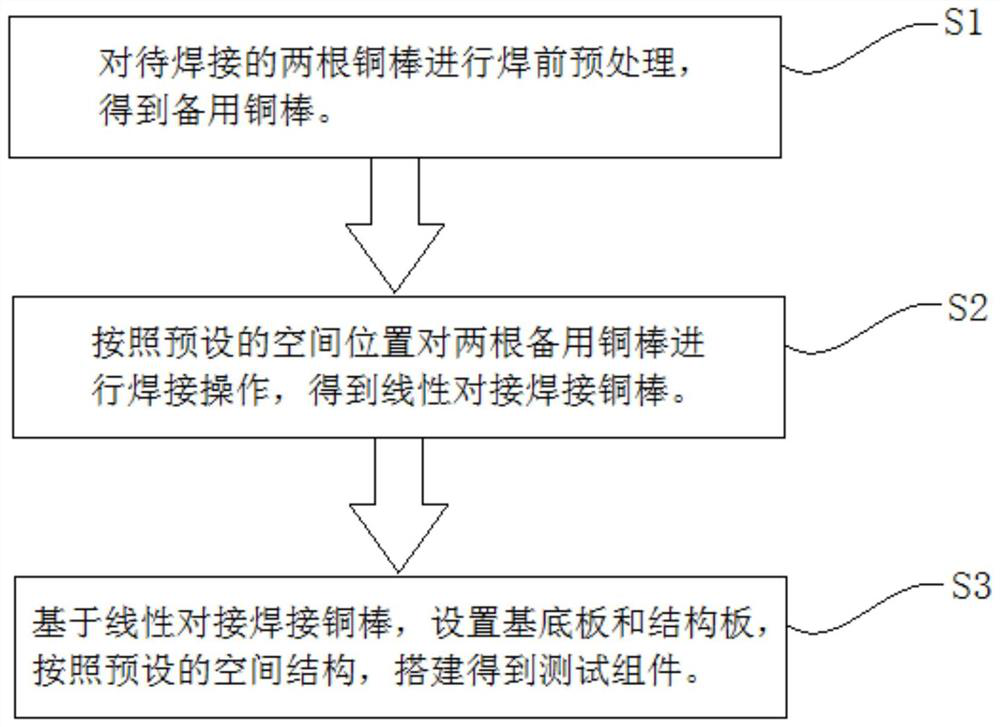

[0042] Such as figure 2 As shown, it is a schematic flow chart of the test component manufacturing method for avoiding the thermal influence of the linear solder joint electromigration process in Embodiment 2 of the present application, which mainly includes the following steps:

[0043] S1. Perform pre-welding pretreatment on the two copper rods to be welded to obtain spare copper rods. Pre-welding pretreatment mainly includes the size selection of copper rods, and the use of appropriate methods to remove the attachments on the surface of copper rods.

[0044] S2. Use solder paste to weld two spare copper rods according to the preset spatial position to obtain linear butt welded copper rods; the selection of solder paste should be based on the target solder joint composition, the spatial position of the copper rods It should be determined according to the size of the target test component and the requirements of the electromigration test. Further, manual grinding may be us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com