Automatic flame brazing machine for copper and aluminum welding

A flame brazing and automatic technology, applied in welding equipment, applications, household appliances, etc., can solve the problems of non-melting welding wire, unsatisfactory welding quality, and difficult welding, so as to improve the stability of welding quality and improve production. Efficiency, the effect of improving welding yield and brazing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

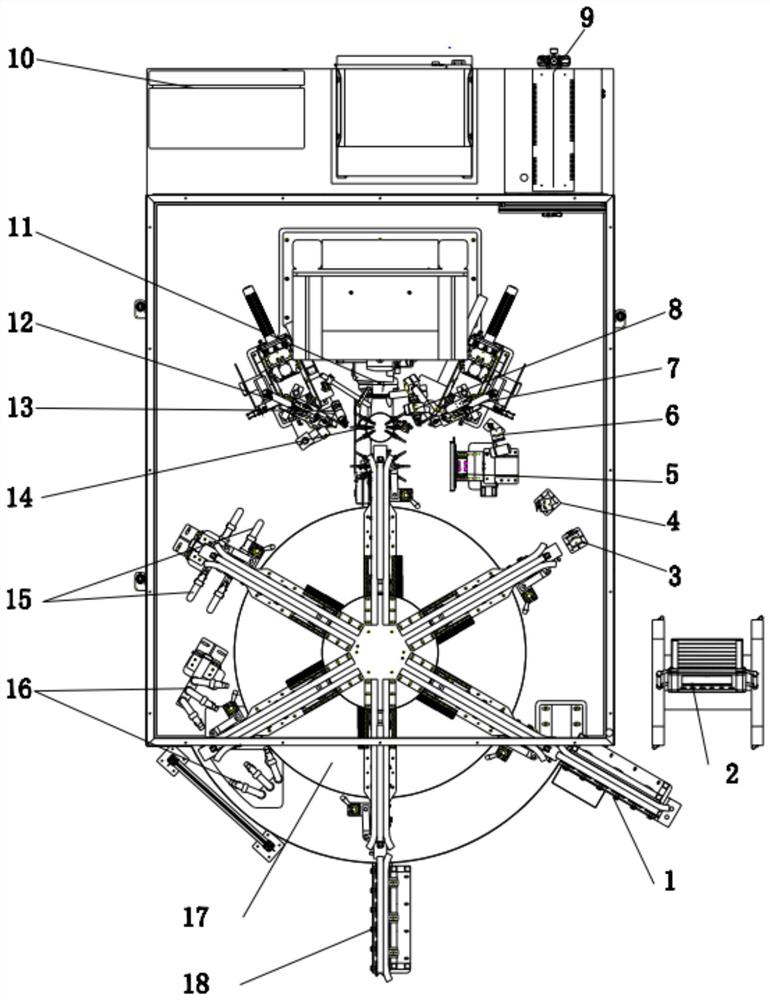

[0023] The automatic flame brazing machine for copper-aluminum welding of micro-channel heat exchangers in the embodiment of the present invention is a six-station turntable automatic flame brazing machine, including a feeding station, a detection station, a welding station, two A cooling station and a blanking station.

[0024] At the loading station, the workpiece on the pre-loading tool 1 can be pushed into place, the protective cover is put on, and solder paste is applied to the welding place. The operation box 2 can use the operation box with button touch screen, which can realize the saving of parameters of various models, quick selection and convenient operation.

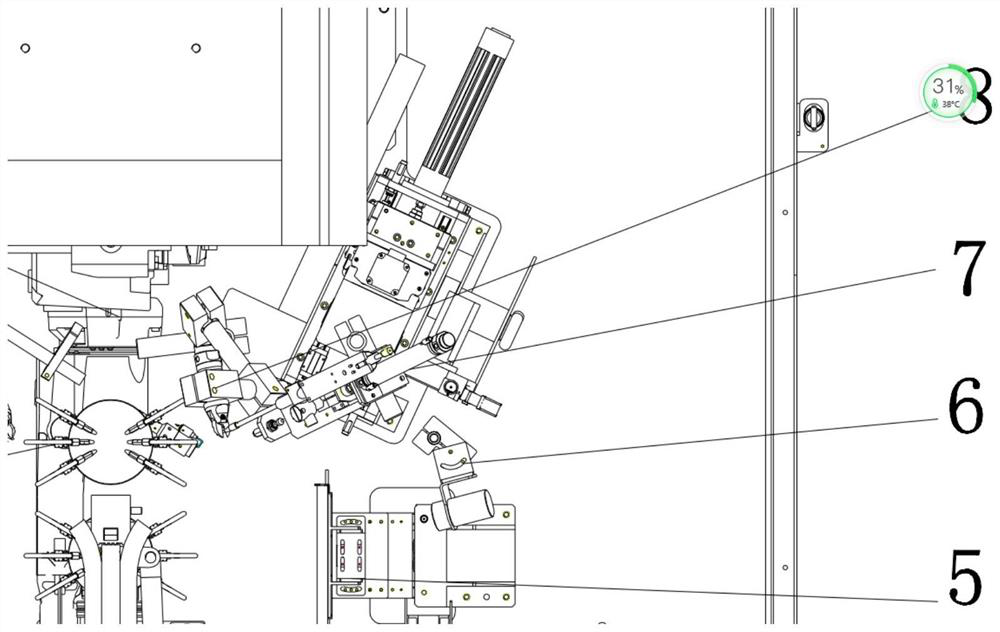

[0025] At the detection station, a detection part 3 for the presence or absence of a protective plate and a detection part 4 for the presence or absence of a workpiece are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com