Guide milling shoe inner nozzle and milling shoe with same

A technology of inner nozzle and shoe grinding, which is applied in the direction of wellbore/well parts, earthwork drilling and production, etc., can solve the problems that affect the smooth progress of mining work, consume manpower and material resources, and poor working conditions, so as to reduce temperature, save cost, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] The specific implementation is described as follows:

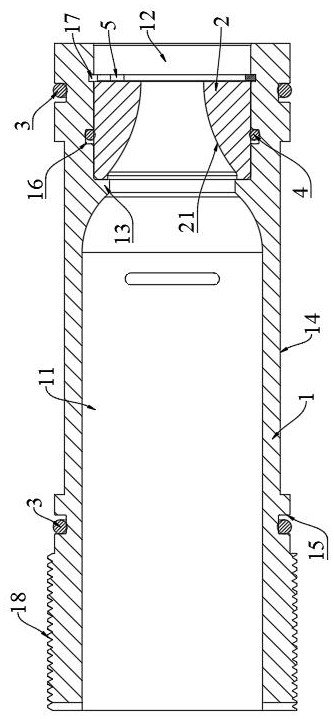

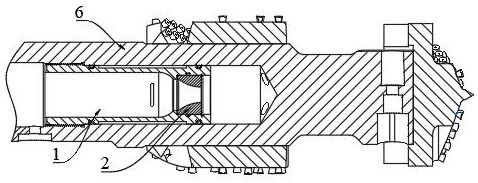

[0029] First, after cleaning each part, put the sealing ring 3 into the first annular groove 15 on the outer wall of the inner cylinder 1, put the second sealing ring 4 into the second annular groove 16, and then install the piston 2 into the inner cylinder 1 In the second recess 12, the piston 2 is abutted against the ring platform 13, and the end of the through hole 21 with a large diameter faces the ring platform 13. With the cooperation of the second sealing ring 4, the piston 2 is stuck in the second recess 12 , put the retaining ring 5 into the limiting groove 17 of the inner cylinder 1 with a circlip pliers, and limit the piston 2; finally screw the nozzle into the grinding shoe with a wrench, and with the cooperation of the first sealing ring 3, the nozzle Got stuck in the mill shoe, at this point the installation is complete.

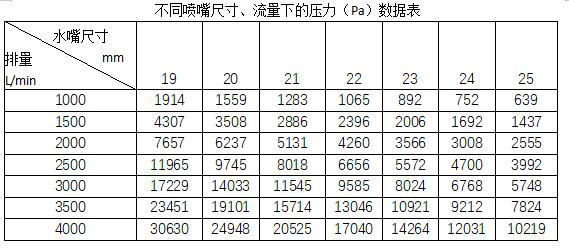

[0030] In this example, the nozzle can realize the control of the flow in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com