A semiconductor packaging method

A packaging method and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of limiting product-related performance improvement and high cost, and avoid pad modification or Effect of RDL process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A semiconductor packaging method, comprising:

[0070] Step A. Mount the chip 2 on the lead frame 1, and use the wire bonding process to make the wire bonding terminal structure 3 on the upper surface AL pad 21 of the chip 2; the wire bonding terminal structure 3 includes a tight connection from bottom to top The wire bonding pad contacts the ball 31, the transition connection table 32 and the wire head 33; Figure 13a and Figure 7 shown.

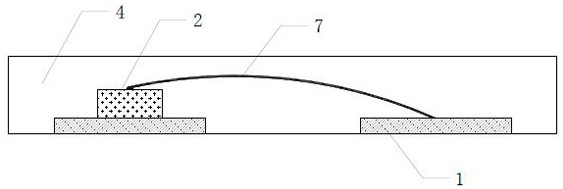

[0071] Step B. The lead frame 1 produced by the wire-bonding terminal structure 3 is plastic-sealed or press-sealed for the first time, so as to realize the complete wrapping of the chip 2 and the wire-bonding terminal structure 3, and the top surface height of the wrapping layer 4 exceeds the height of the wire bonding terminal structure 3. The top surface of the wire end structure 3 is 20~50 μm; combined Figure 13b shown.

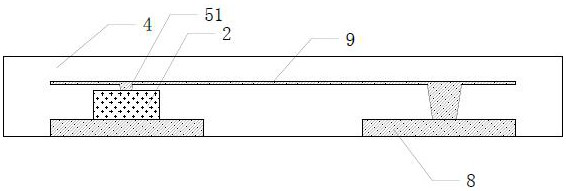

[0072] Step C. Thin the wrapping layer 4 until the wire bonding pad contact ball 31 is exposed, and rem...

Embodiment 2

[0075] A semiconductor packaging method, comprising:

[0076] Step A. Mount the chip 2 on the lead frame 1, and use the wire bonding process to make the wire bonding terminal structure 3 on the upper surface AL pad 21 of the chip 2; the wire bonding terminal structure 3 includes a tight connection from bottom to top The wire bonding pad contacts the ball 31, the transition connection table 32 and the wire head 33; Figure 13a and Figure 7 shown.

[0077] Step B. The lead frame 1 produced by the wire-bonding terminal structure 3 is plastic-sealed or press-sealed for the first time, so as to realize the complete wrapping of the chip 2 and the wire-bonding terminal structure 3, and the top surface height of the wrapping layer 4 exceeds the height of the wire bonding terminal structure 3. The top surface of the wire end structure 3 is 20~50 μm; combined Figure 13b shown.

[0078] Step C. Thin the wrapping layer 4 until the wire bonding pad contact ball 31 is exposed, and rem...

Embodiment 3

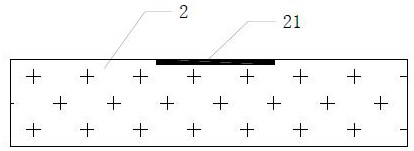

[0087] In this embodiment, the wire used in the wire bonding process is a variable-diameter wire, and the variable-diameter wire includes N or more ball-binding units 6 connected to each other, and each ball-binding unit includes a wire head 61 and a diameter-reducing part 62 And the joint part 63, the diameter of the wire head 61 and the joint part 63 is equal to the diameter of the wire, the diameter of the reducing part 62 is large and the two ends are small, and the maximum diameter of the reducing part 62 is 2~4 times the diameter of the wire. Figure 14 shown.

[0088] N is a natural number, and N is greater than or equal to 10.

[0089] The diameter reducing portion 62 includes a middle main body ball 621 and transition connection balls 622 on both sides. When making the wire-bonding end structure 3, the middle main body ball 621 becomes the main body of the wire bonding pad contacting ball 31, and the transition connection balls 622 are melted respectively. The two si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com