Preparation process of environment-friendly disinfectant

A preparation process and technology for disinfectant, applied in the directions of disinfectants, botanical equipment and methods, chemicals for biological control, etc. Disinfection cost, improve disinfection effect, reduce volatilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] see figure 1 , a kind of environment-friendly disinfectant preparation process, comprises the following steps:

[0047] S1. Take 50-60 parts of peppermint, wild chrysanthemum, scutellaria baicalensis, honeysuckle, angelica dahurica, and purslane according to the number of parts after washing, crushing, grinding and mixing uniformly to obtain disinfection auxiliary materials;

[0048] S2. Take 10-15 parts of deionized water and mix with disinfection auxiliary materials for decoction, then filter to remove the filter residue, retain the filtrate and perform decolorization treatment;

[0049] S3. Add 15-20 parts of medical alcohol, 2-10 parts of glycerin, and 2-6 parts of dispersant to the filtrate, and stir and mix evenly under the condition of heating in a water bath at 50-70°C to obtain a disinfectant;

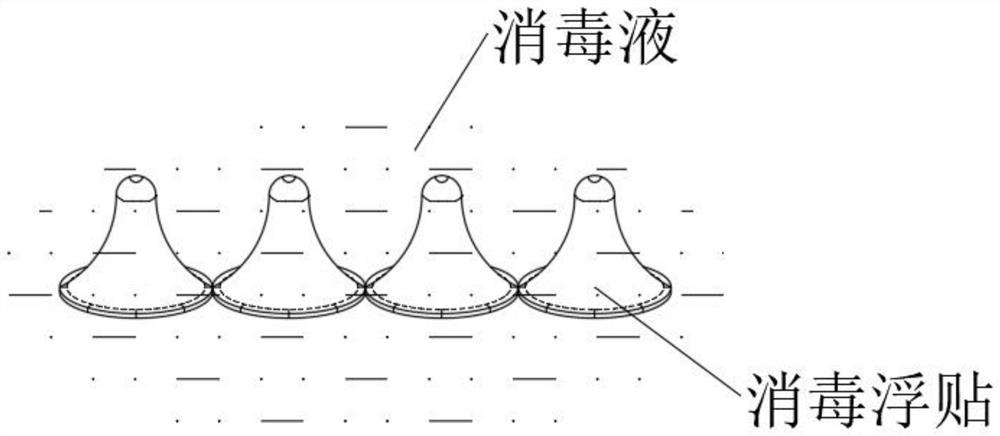

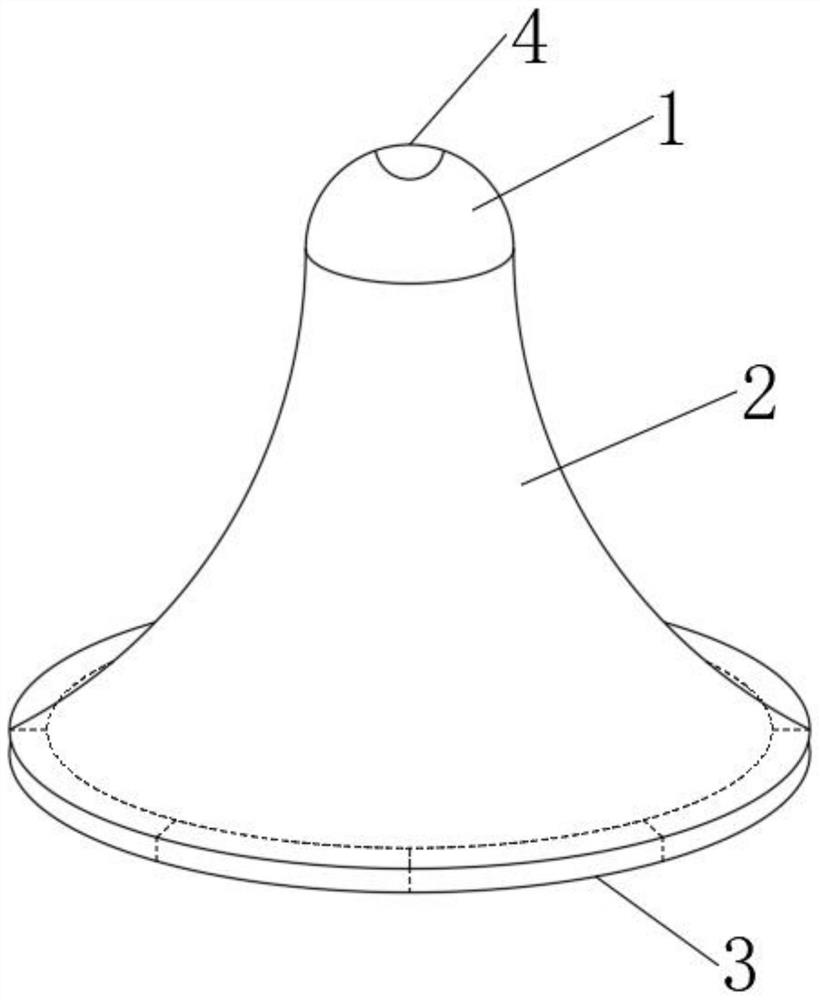

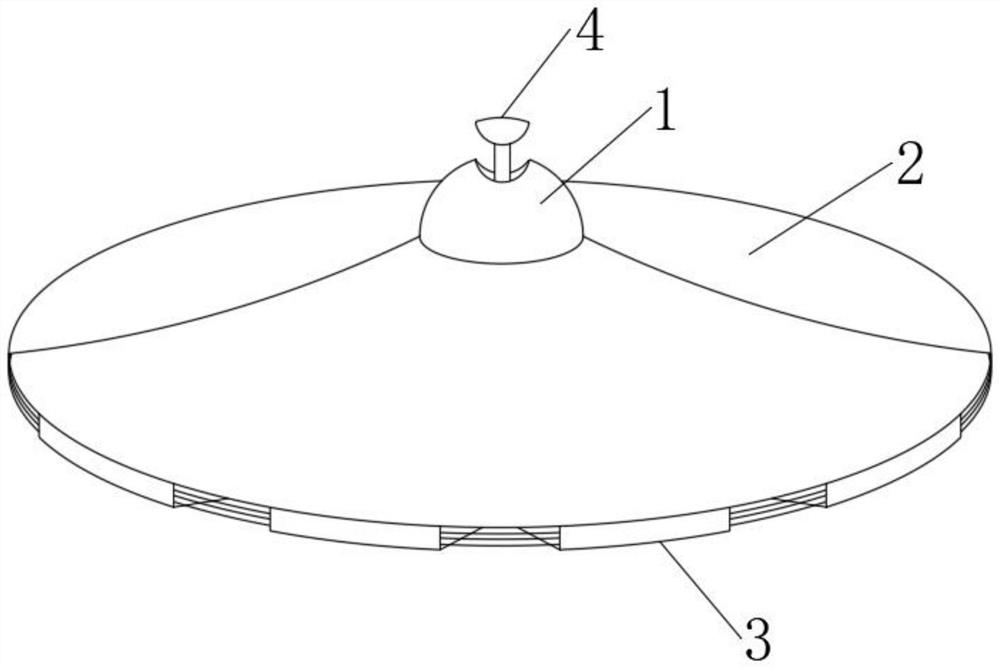

[0050] S4. Fill the disinfectant into the container, and then put in multiple disinfectant stickers to make them float on the surface of the disinfectant.

[0051] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com