Cooling water flow acquisition method and correction method for hot-rolled alloy steel laminar flow cooling jet header

A technology of cooling water flow rate and laminar flow cooling, which is applied in workpiece cooling devices, metal rolling, metal rolling, etc., and can solve the problem of low feed-forward control accuracy of rolled piece temperature and large preset error of cooling water flow rate in injection header , Cooling rate is difficult to control and other problems, to achieve the effect of fewer assumptions and simplified conditions, faster calculation speed, and improved control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

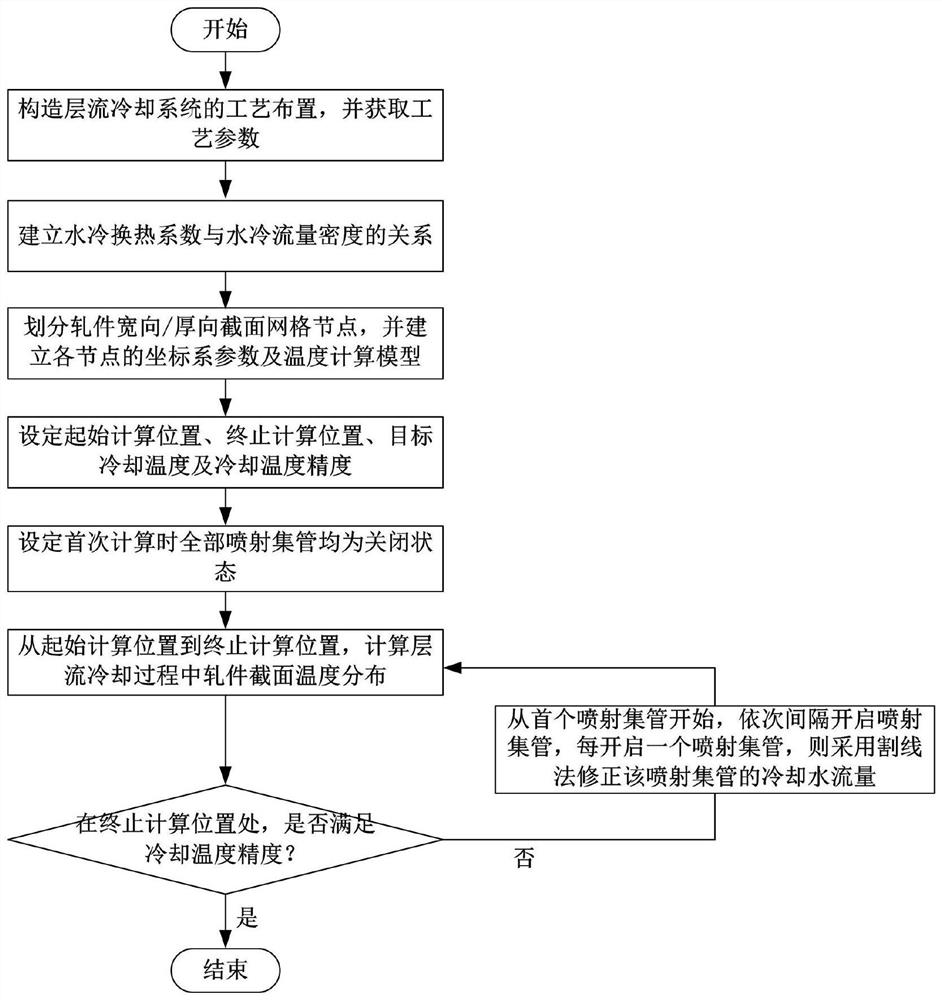

[0078] see figure 1 , the embodiment of the invention provides a cooling water flow acquisition method for hot-rolled alloy steel laminar flow cooling injection header, comprising the following steps:

[0079] S1. Construct the process layout of the laminar flow cooling system, and obtain the process parameters, including the number of spray headers, the center position of each spray header, the spray width, the length of the spray area and the maximum cooling water flow, the thickness, width and speed of the rolled piece , initial temperature and thermophysical parameters.

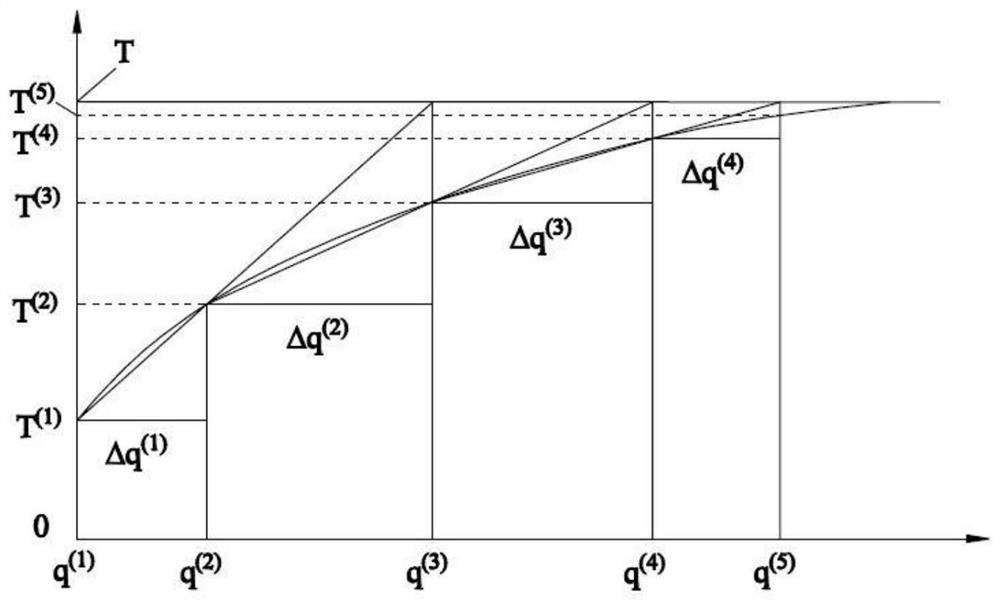

[0080] S2. Establish the relationship between the water-cooling heat transfer coefficient and the water-cooling flow density; the establishment of the relationship between the water-cooling heat transfer coefficient and the water-cooling flow density is obtained by the water-cooling test, and the corresponding water cooling under the corresponding water-cooling flow density is calculated by the linear int...

Embodiment 2

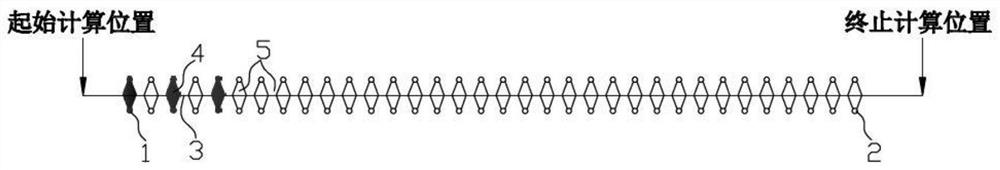

[0151] In this embodiment, the hot-rolled alloy steel 40CrMoV is taken as an example. On the basis of the method described in Embodiment 1, the preset value of the cooling water flow rate of each spray header in the laminar cooling process is calculated, and the temperature value measured on the spot is compared with A comparison is made to further illustrate the versatility and accuracy of the method of the present invention. The process layout of the laminar flow cooling system is as follows: image 3 As shown, the number of injection headers is 34, and the number from the laminar flow cooling inlet to the outlet is 1# to 34#. The serial number, center position, spray width, spray area length and maximum cooling water flow of each injection header are shown in the table 1 As shown in the first column to the fifth column, the thickness of the rolled piece is 2mm, the width is 1600mm, the initial temperature is 880°C, the thermal conductivity of the rolled piece is 34W / (m×°C),...

Embodiment 3

[0163] An embodiment of the present invention provides a cooling water flow correction method for a hot-rolled strip laminar flow cooling injection header, which includes the following steps:

[0164] SS1. After each injection header is turned on, judge whether the existing cooling water flow of the injection header reaches the maximum flow rate. If the existing cooling water flow rate of the injection header does not reach the maximum flow rate, correct the cooling water flow of the injection header. For water flow rate, change the cooling water flow rate once every time it is corrected, and then go to step SS2; The cooling water flow preset value of the tube, and open the next injection header to make corrections;

[0165] SS2. When judging whether the difference between the surface temperature of the rolled piece at the specified position and the target cooling temperature satisfies the cooling temperature control accuracy, if the difference between the surface temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com