Numerical control machine tool visual positioning system and method

A technology of visual positioning and CNC machine tools, which is applied to metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problems that affect the positioning accuracy, the positioning accuracy depends on the accuracy of mechanical parts, and the debugging process is cumbersome, etc., to achieve The effect of fast and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

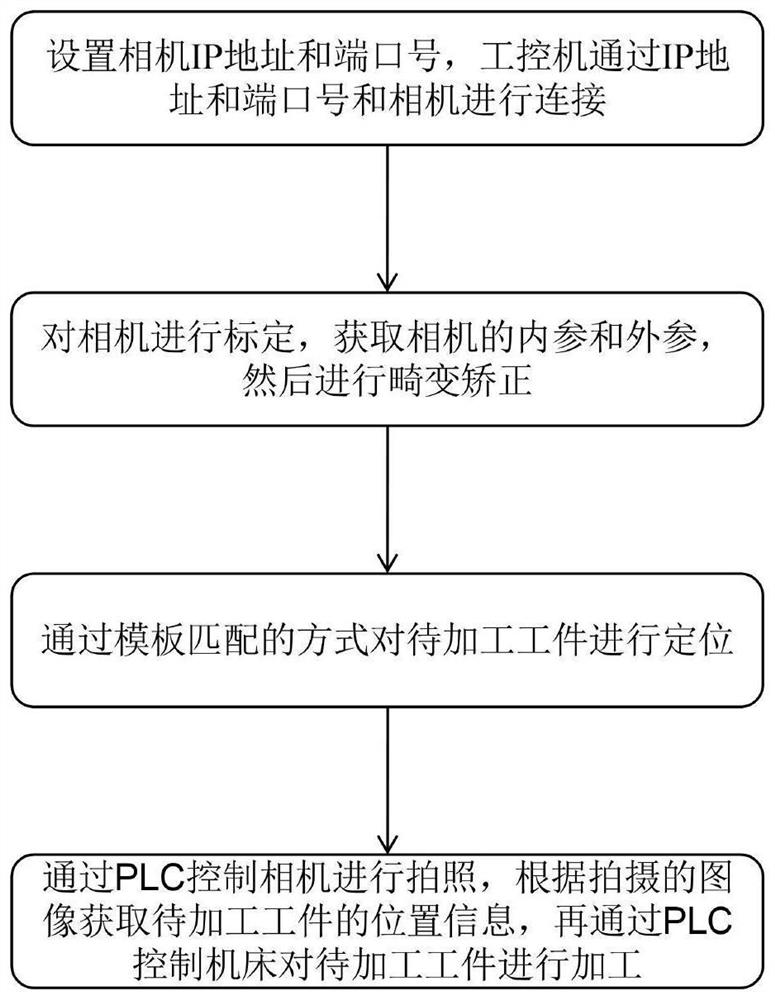

[0031] Before the product is processed, the present invention obtains the template outline of the product through visual software, searches the template outline in the entire image during product processing, and sends the center coordinates and rotation angle of the template to the machine tool for processing after finding the template.

[0032] According to the numerical control machine vision positioning system provided by the present invention, comprise following module:

[0033] Connect the camera module: set the camera IP address and port number, set the model of the camera to be connected, the industrial computer connects with the camera through the IP address and port number, set the trigger mode of the camera to control the camera to take pictures, the trigger mode has two types: soft trigger and hard trigger There are two modes, the soft trigger is the software triggers the camera to take pictures by sending instructions, and the hard trigger is to use a high level to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com