Hydrolysate waste acid neutralization facility

A hydrolyzate and facility technology, applied in neutralization water/sewage treatment, dissolution, transportation and packaging, etc., can solve problems such as low efficiency, labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

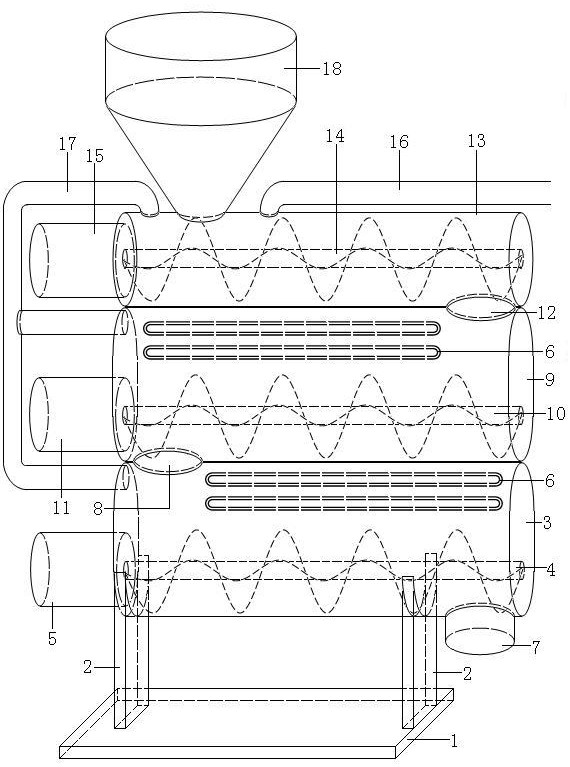

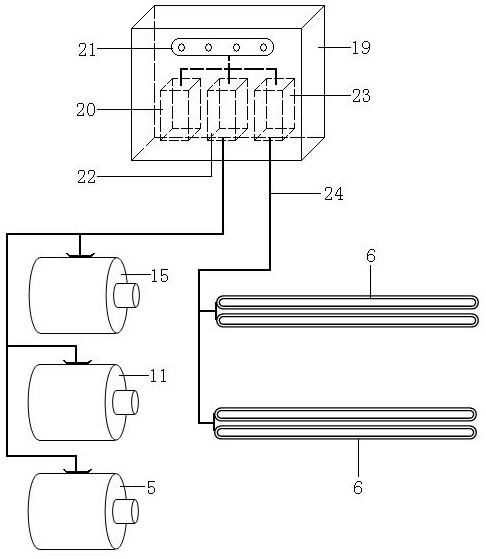

[0017] Now in conjunction with accompanying drawing and reference numeral, shape, structure of the present invention are described in detail:

[0018] A hydrolyzate waste acid neutralization facility is characterized in that it includes a base 1, a vertical plate 2, a third-stage stirring tank 3, a third-stage stirring shaft 4, a No. 3 reduction motor (AC380V2-5kw) 5, a heat pipe (AC380V30- 40kw) 6. Discharge port 7, secondary feeding port 8, secondary mixing tank 9, secondary stirring shaft 10, No. 2 gear motor (AC380V2-5kw) 11, primary feeding port 12, primary mixing tank 13. Primary stirring shaft 14. No. 1 deceleration motor (AC380V2-5kw) 15. Waste acid feed pipe 16. Steam recovery pipe 17. Hopper 18. Distribution box 19. Power supply (AC380V / 400A) 20. Switch button ( AC220V / 2A) 21, No. 1 contactor (AC380V / 80A) 22, No. 2 contactor (AC380V / 300A) 23, power cord (4x18mm²) 24;

[0019] The base 1 is rectangular, horizontally and horizontally arranged on the ground, a rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com