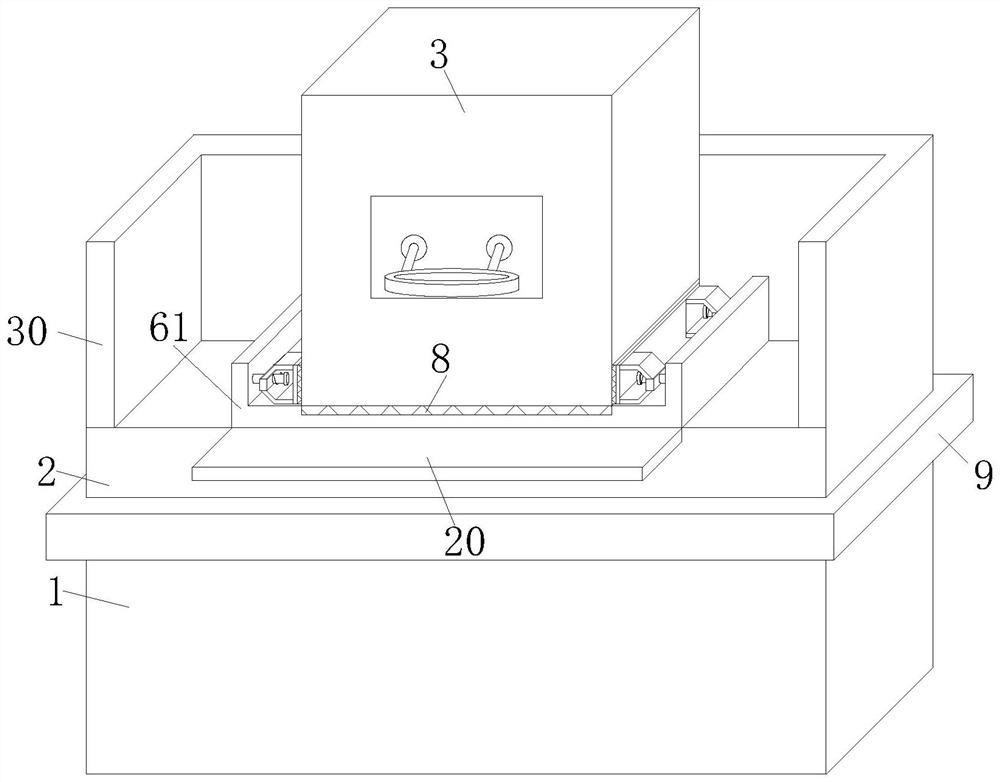

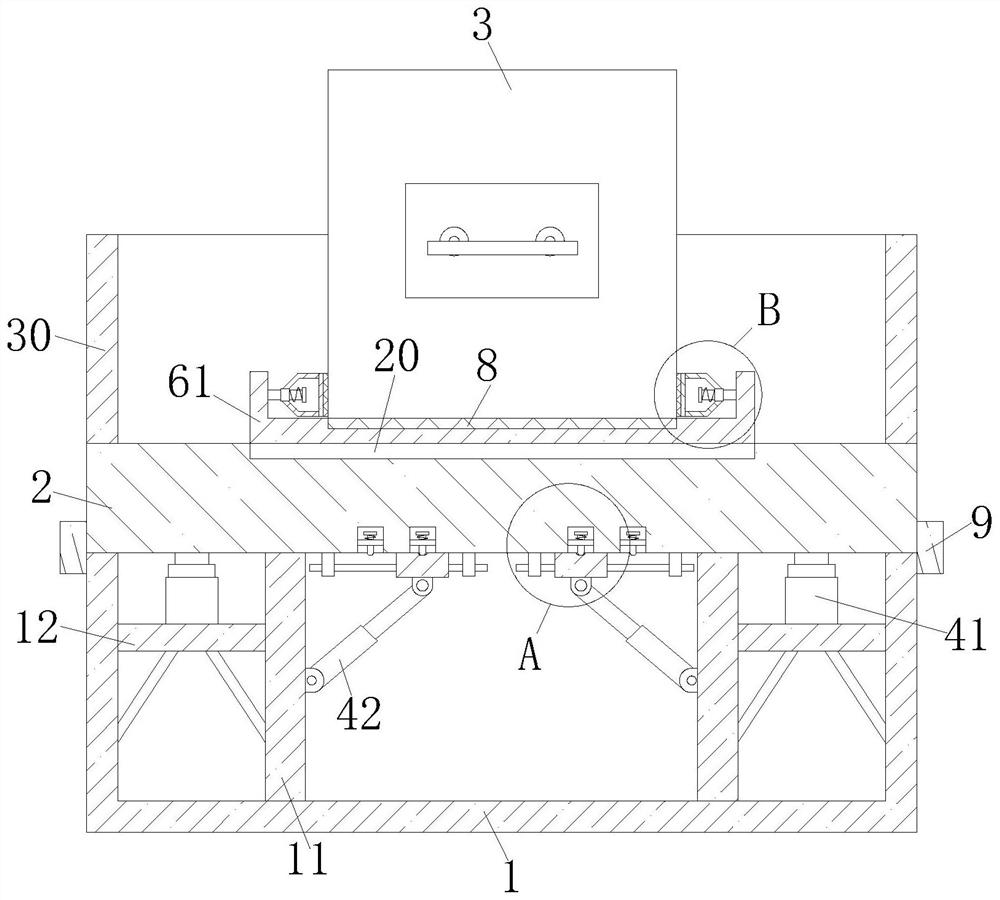

Heat treatment equipment for metal processing and manufacturing

A technology for heat treatment equipment and metal processing, applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., which can solve problems such as inconvenient use, lack of adjustment mechanisms in workbenches, and reduced heat treatment efficiency of metal materials, so as to improve practicability and heat treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

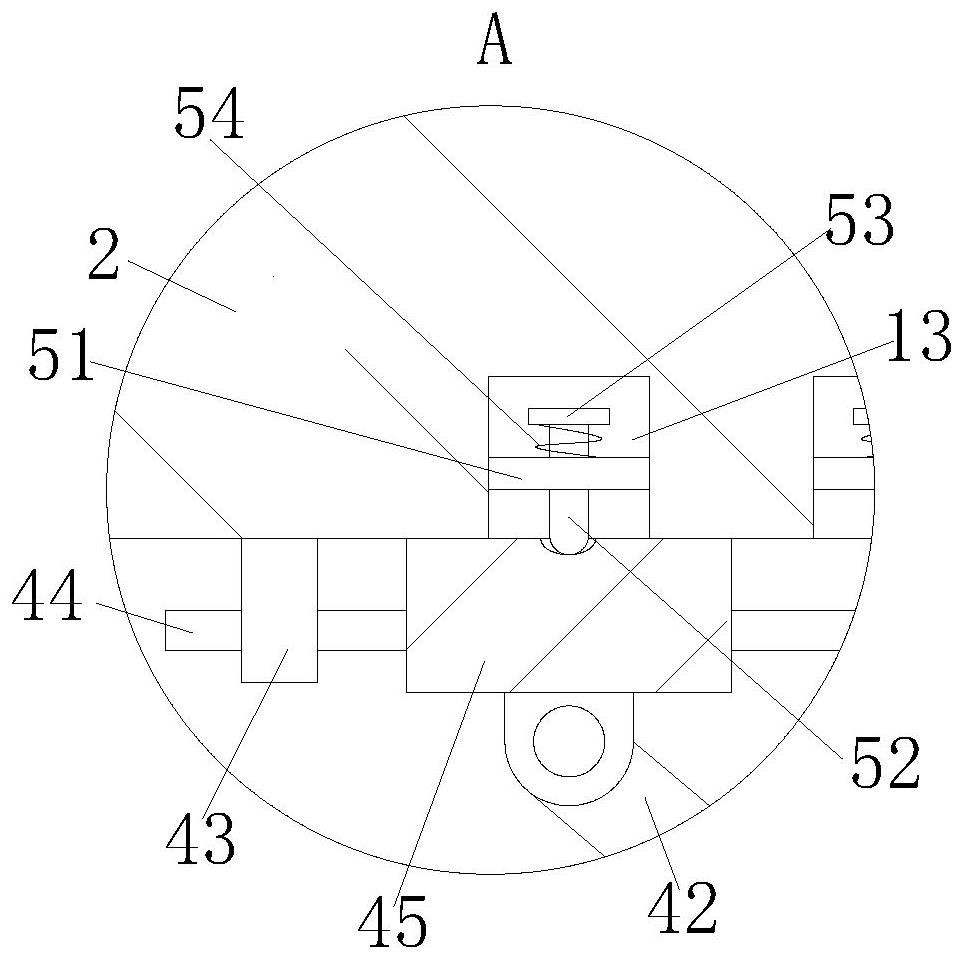

[0028] As an embodiment of the present invention, the inner wall of the bottom of the first workbench 2 is provided with a square groove 13; the inside of the square groove 13 is provided with a clamping assembly; the clamping assembly is in contact with the groove; The connecting assembly includes a bracket 51, an extruding rod 52, a first limit block 53 and a first spring 54; both ends of the bracket 51 are fixed on the side wall of the square groove 13; , and slidingly fit with the inner wall of the bracket 51; the bottom of the extrusion rod 52 is in contact with the groove; the first limit block 53 is fixed on the top of the extrusion rod 52; the first spring 54 is sleeved on the extrusion The outer wall of the top end of the rod 52 ; one end of the first spring 54 is fixedly connected to the bottom of the first limiting block 53 , and the other end is fixedly connected to the top of the bracket 51 .

[0029] During work, when the first workbench 2 lifts the heat treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com