Stationary pile foundation scouring protection structure of offshore wind turbine and construction method of stationary pile foundation scouring protection structure

A technology for offshore wind turbines and protective structures, applied in infrastructure engineering, protective devices, buildings, etc., can solve the problems of high cost, poor effect, and difficult erosion protection, and achieve low manufacturing cost, high environmental friendliness, and meet the requirements of anti-corrosion protection. The effect of flushing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples, but the usage of the present invention is not limited thereto.

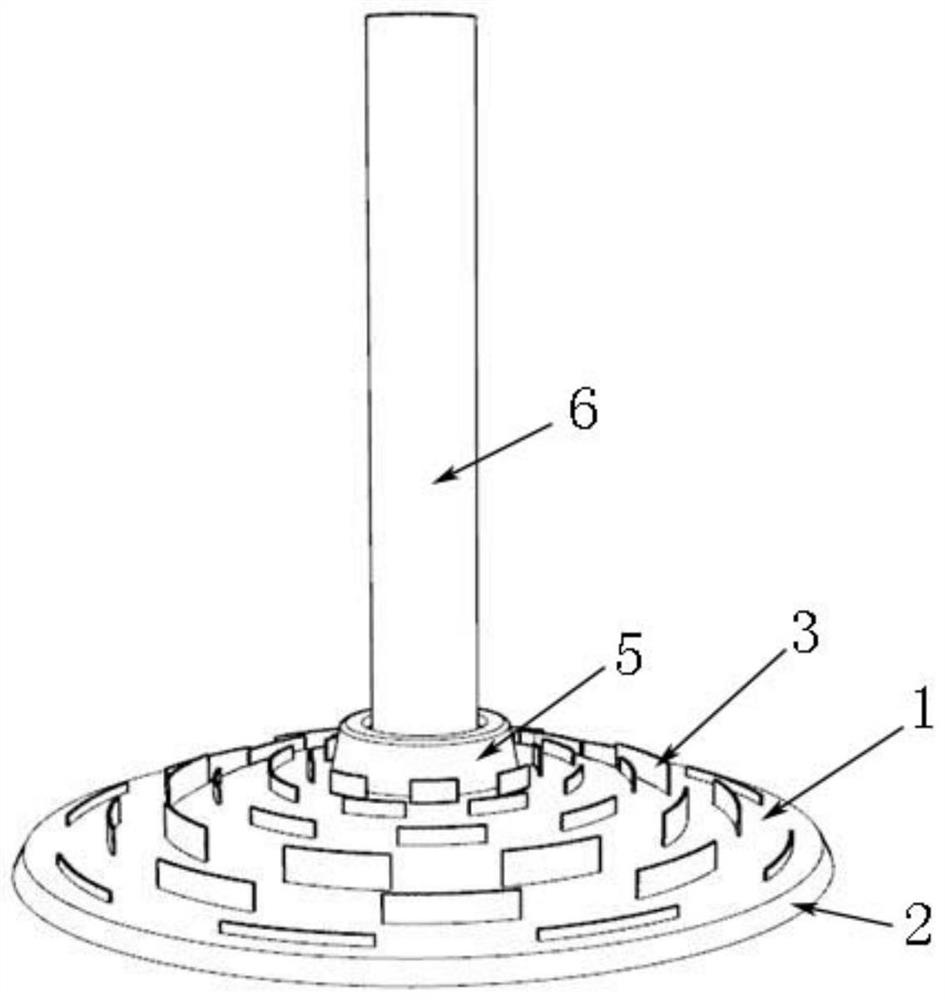

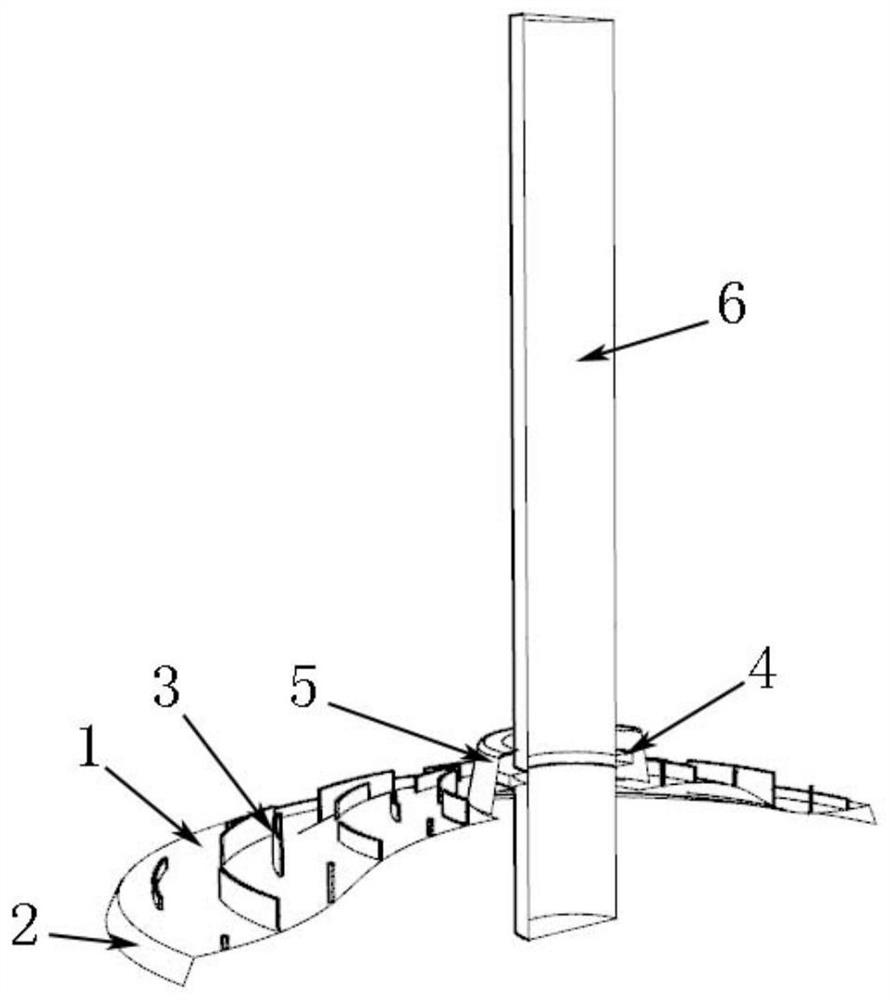

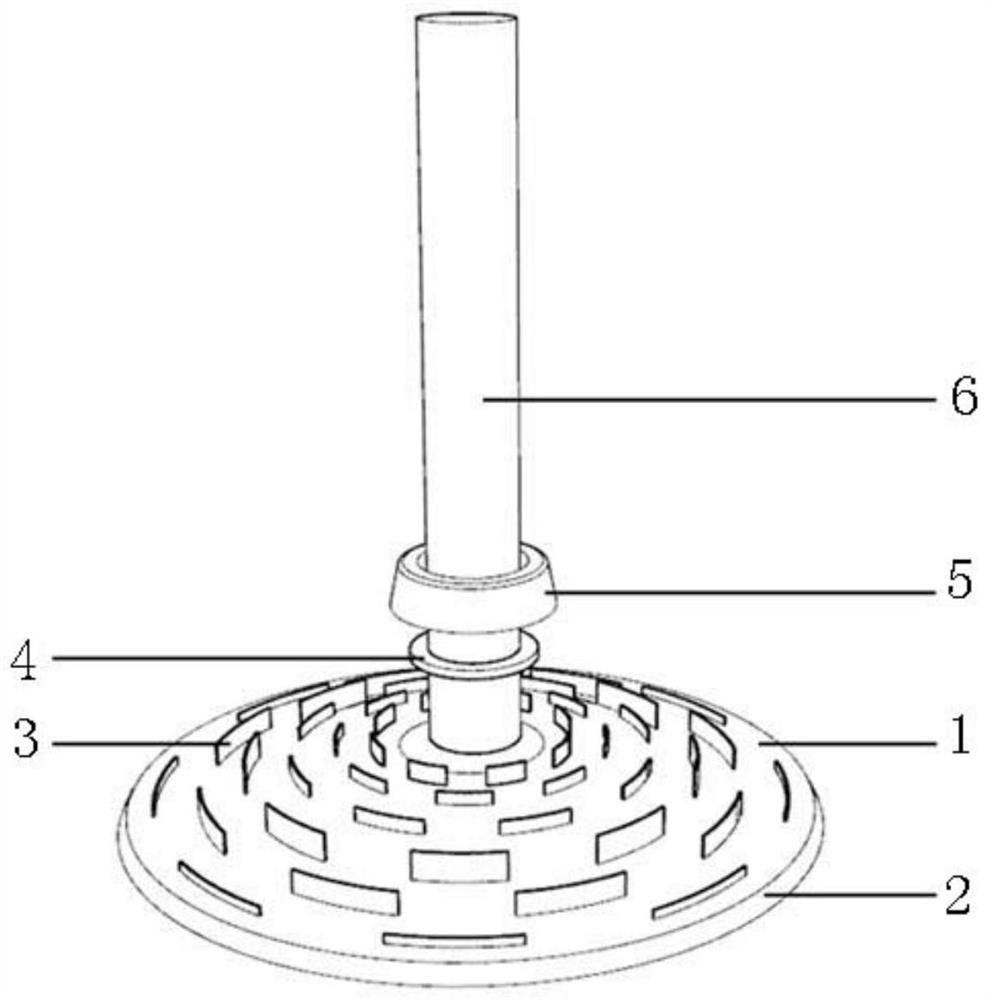

[0023] Such as Figure 1 to Figure 4 As shown, this embodiment provides a fixed pile foundation scour protection structure for offshore wind turbines, including a protective chassis 1, an annular anchor plate 2, a water ladder 3, a fixing ring 4 and a fairing 5; the protective chassis 1 is an inverted plate Shaped structure, the bottom of which fits on the seabed, the outer peripheral edge of the bottom is processed with an annular anchor plate 2 for inserting into the seabed to fix the protective chassis 1, and the top is staggered with several circles of water ladders 3 along the radial direction for blocking and Change the flow direction of the water flow and reduce the starting ability of the water flow to the sediment on the seabed surface. An installation hole 101 for the pile foundation 6 to pass through is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com