Device and method for rapidly testing heat conductivity coefficient of vacuum insulated panel

A technology of vacuum insulation panels and thermal conductivity, applied in the direction of material thermal development, can solve problems such as energy consumption, achieve good protection and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-8 The application is described in further detail.

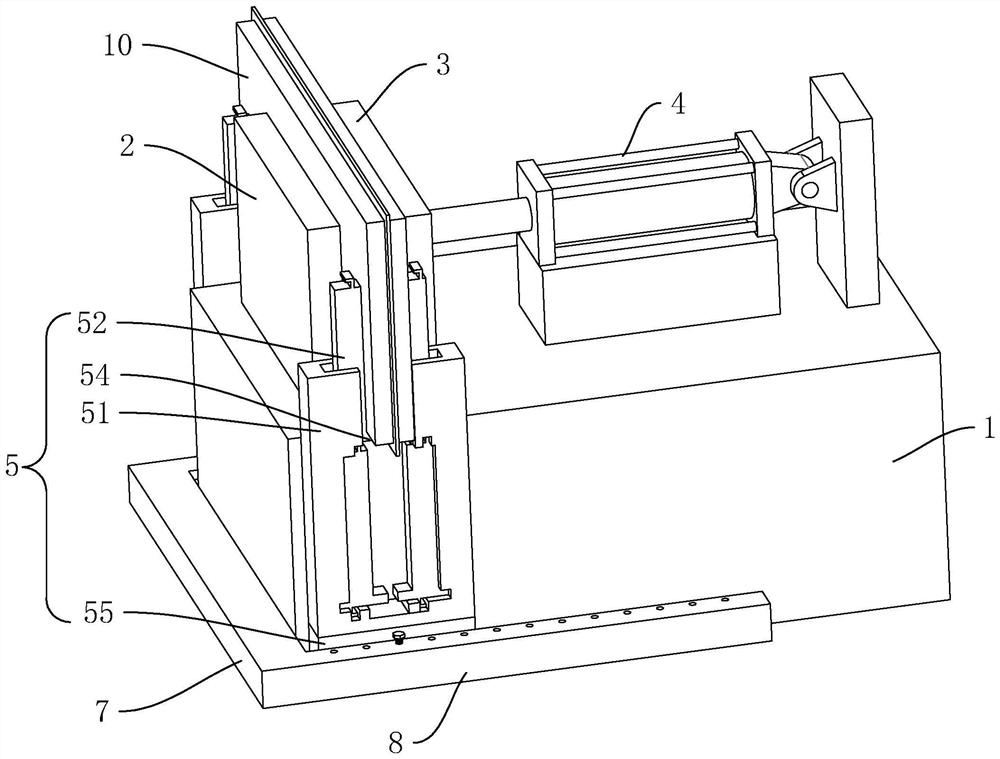

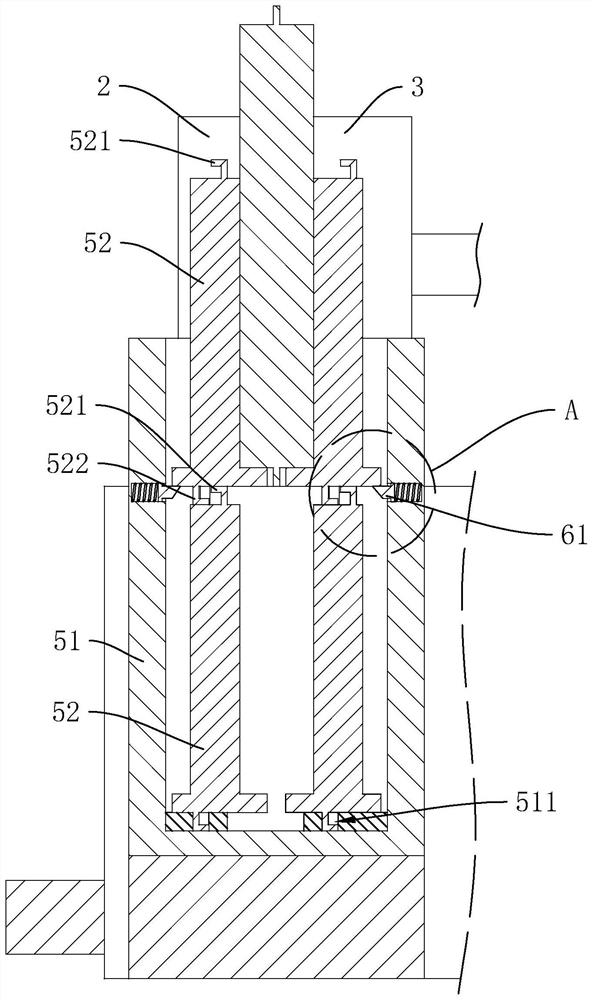

[0046] The embodiment of the present application discloses a rapid testing device for thermal conductivity of a vacuum insulation panel. refer to figure 1 , The rapid test device for thermal conductivity of vacuum insulation panels includes a connection box 1, a heating plate 2 and a heat flow sensor 3 parallel to the heating plate 2 are installed on the connection box 1, and a heat flow sensor 3 is installed on the connection box 1 to drive the heat flow sensor 3 to the heating plate. 2 close hydraulic press 4. When testing the vacuum insulation panel 10 , the heating plate 2 and the heat flow sensor 3 clamp the vacuum insulation panel 10 .

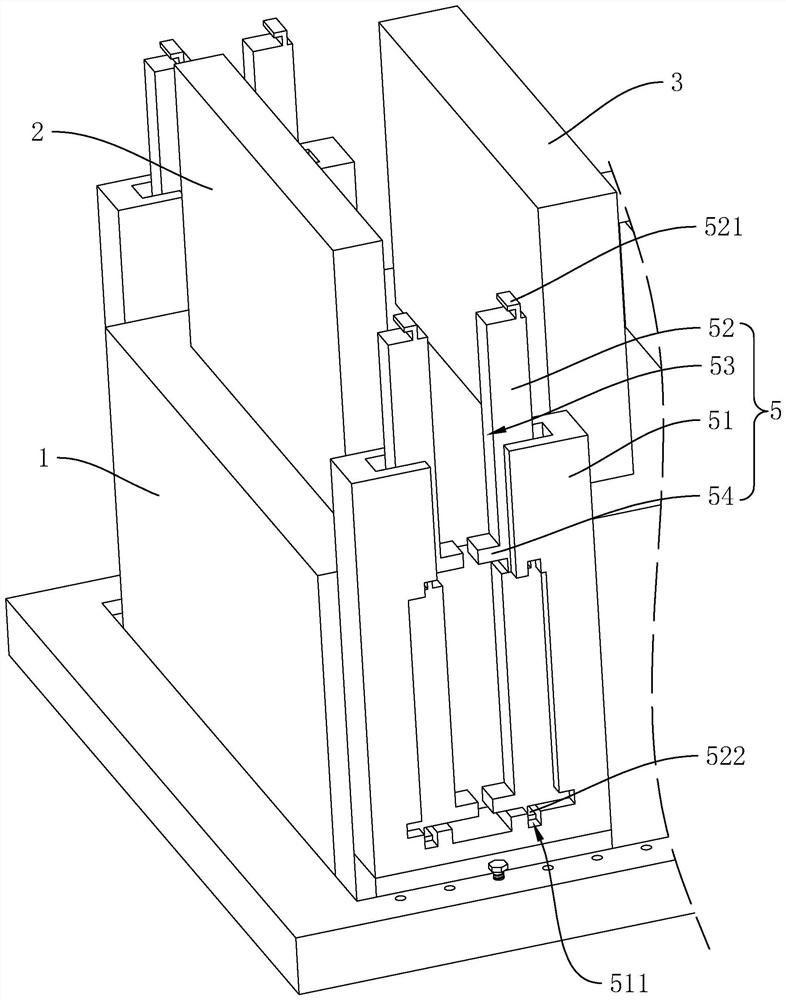

[0047] refer to figure 1 and figure 2 , The device for quickly testing the thermal conductivity of the vacuum insulation panel further includes a positioning mechanism 5 for positioning the vacuum insulation panel 10 . There are two posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com