Anti-splashing laser tin soldering equipment and welding method

A laser welding and anti-splash technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of tin spatter, low gasification temperature, low melting point, etc., and achieve the effect of solving tin spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The above and other embodiments and advantages of the present invention are clearly and completely described below with reference to the accompanying drawings. Apparently, the described embodiments are only some, not all, embodiments of the present invention.

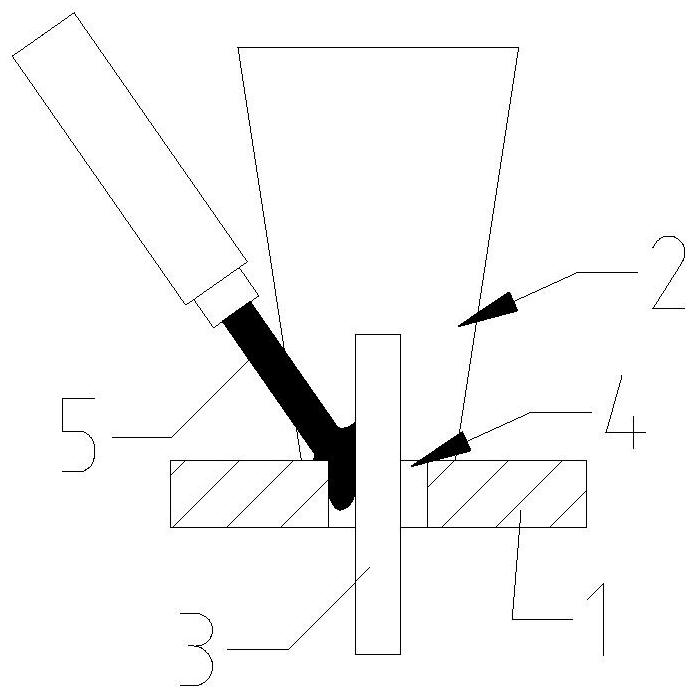

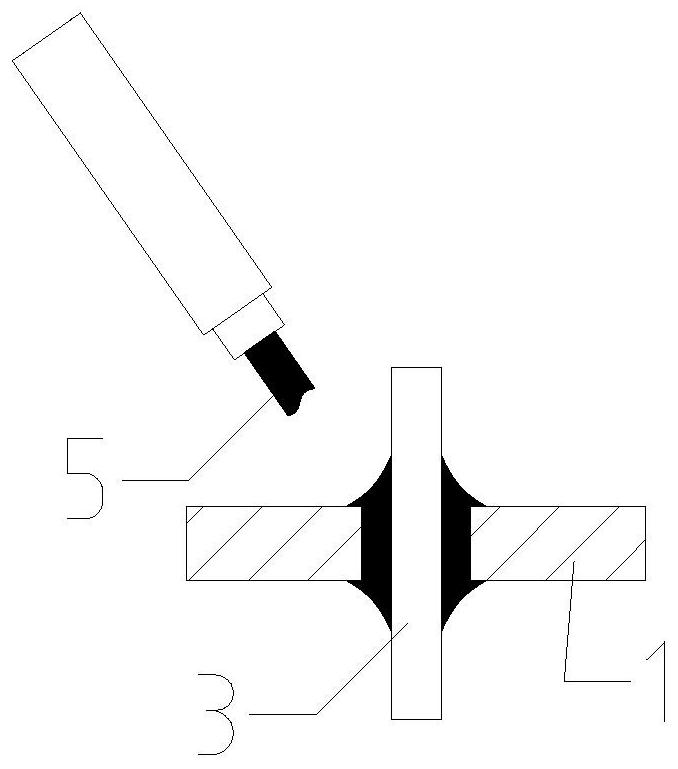

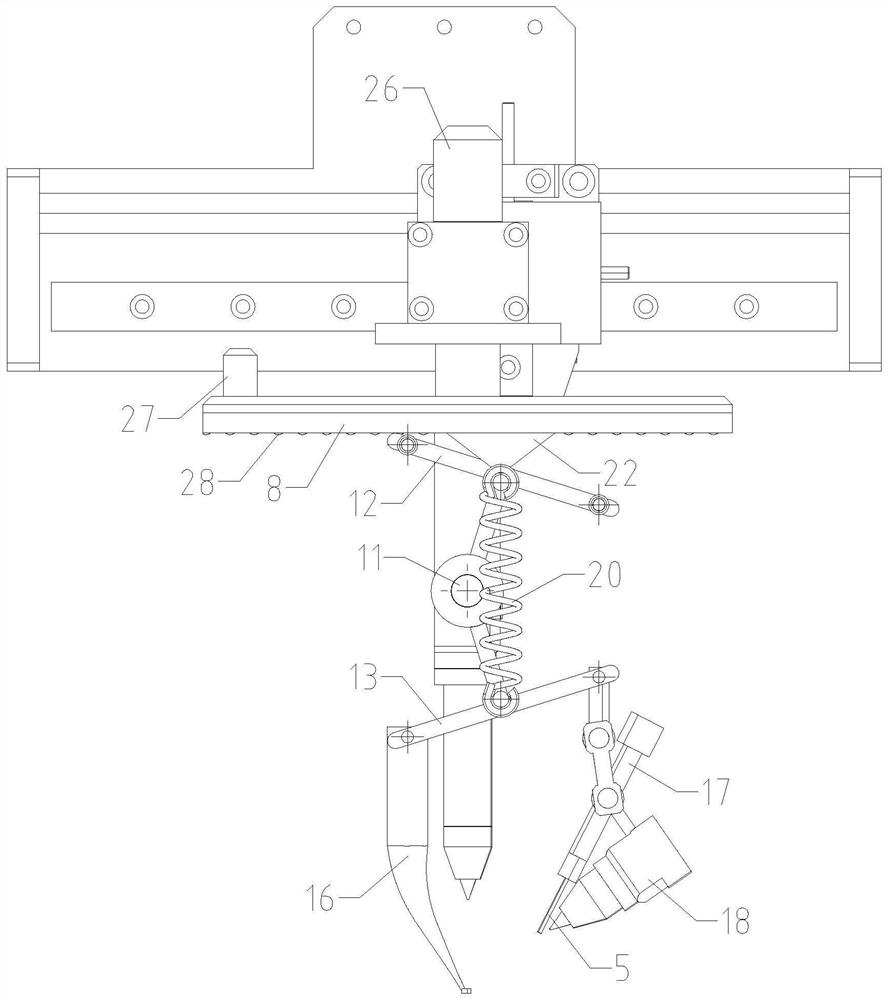

[0031] In one embodiment, as Figure 3-5 shown.

[0032] The spatter-proof laser soldering equipment provided in this embodiment includes a mobile module 6, on which a cantilever 7 protruding in the horizontal direction is provided, and a rotating plate 8 is provided below the cantilever 7, and the rotating plate 8 A vertical arm 9 and a first laser head 10 along its axis are arranged below, a suspension shaft 11 protruding out along the horizontal direction is provided on the suspension arm 9, and a T-shaped upper swing rod 12 and an inverted T-shaped upper swing rod 12 are sleeved on the suspension shaft 11. Shaped lower swing rod 13, the two ends of the upper swing rod 12 are provided with a contact shaft 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com