Production equipment of reinforced and toughened composite pipe

A production equipment, strengthening and toughening technology, applied in the field of composite pipes, can solve the problems of weak bonding, limited improvement of the quality and strength of composite pipes, limited bonding force, etc., and achieve high production efficiency, high strength, and layout length. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is a specific embodiment of the present invention and in conjunction with the accompanying drawings, further describes the technical solution of the present invention, but the present invention is not limited to this embodiment.

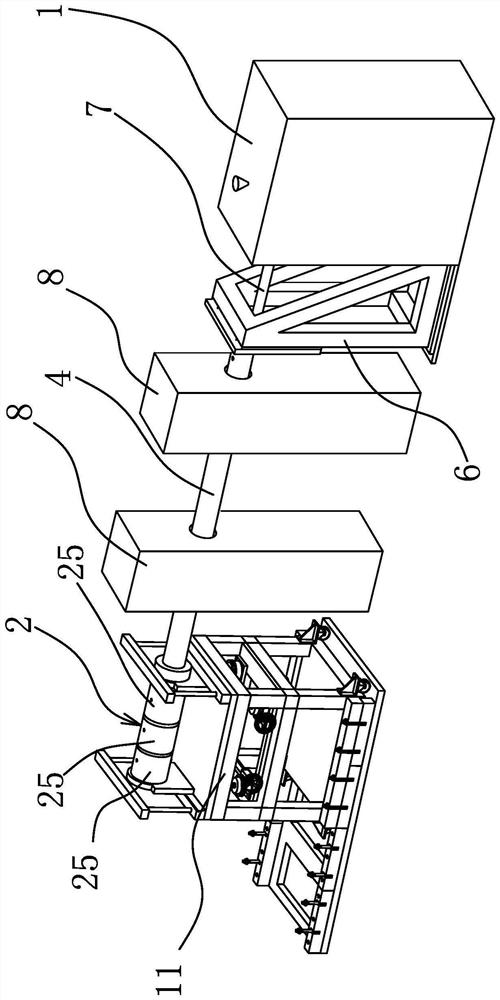

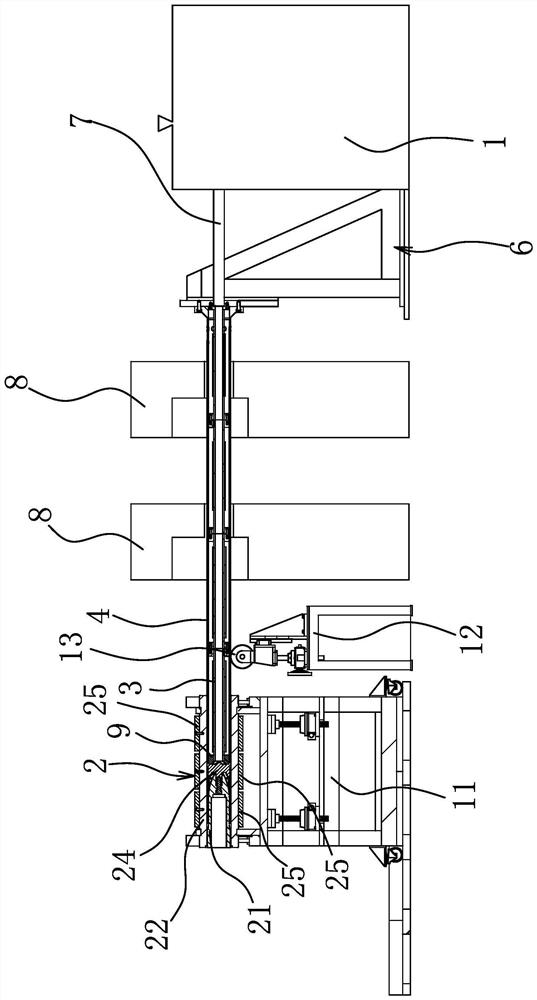

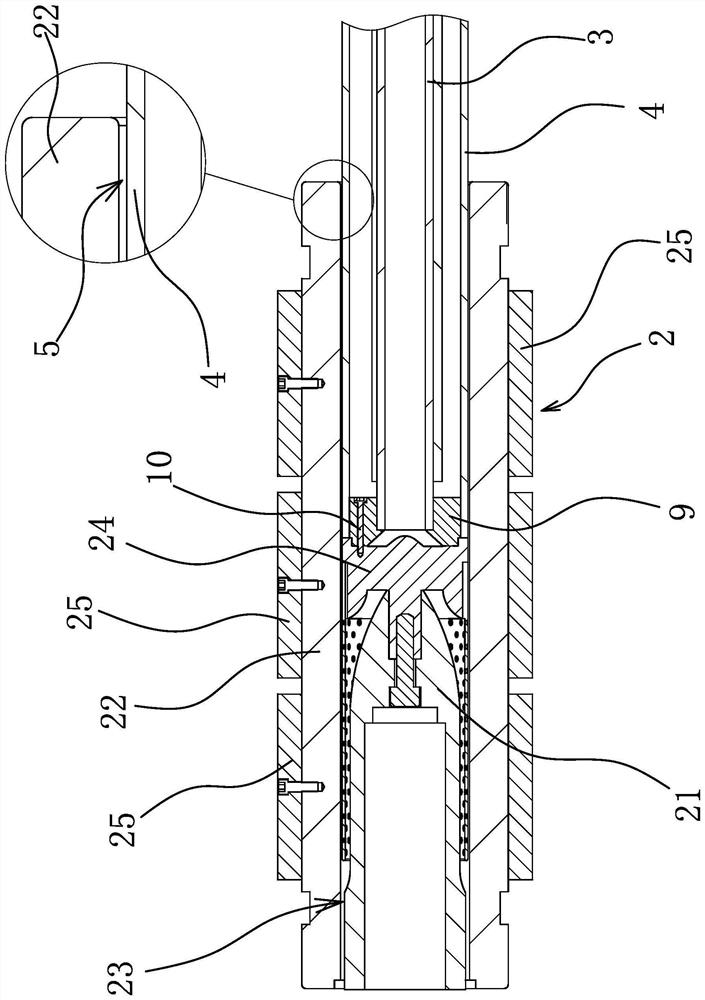

[0026] like figure 1 and figure 2As shown, the production equipment of the reinforced and toughened composite pipe includes an extruder 1, an outer pipe support frame 6, two winding machines 8, a molding die 2, a vacuum calibrating box 14, a tractor 15 and a pipe cutting machine arranged in sequence. machine16. An outer tube 4 is connected between the molding die 2 and the outer tube support frame 6 , and a core tube 3 is coaxially threaded inside the outer tube 4 . An end of the outer tube 4 away from the molding die 2 and an inlet end of the core tube 3 are connected to the outer tube support frame 6 . The extruder 1 is connected with the discharge pipe 7 that is communicated with its extrusion port, and the outlet end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com