Preparation method of terrazzo-imitated ceramic plate with concave-convex texture and ceramic plate

A technology of terrazzo and ceramic plate, which is applied in the field of ceramic processing, can solve the problems of slow update speed, single three-dimensional texture, and insufficient antifouling performance, and achieve the effects of improving wear resistance hardness, improving antifouling ability, and overcoming insufficient protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A preparation method of a terrazzo-like ceramic plate with concave-convex texture, comprising the steps of:

[0047] (1) Body forming

[0048] Press the green body powder into a ceramic green body; transport the formed green body to a drying kiln for drying; after the green body passes through the drying kiln, directly spray digital surface glaze ink;

[0049] In this step, the base powder is a solid base or a speckled base. The design of the spotted blank can create a whole-body brick feeling between the blank and the glaze layer, so that the spotted texture of the natural stone can be seen from the side of the panel.

[0050] Among them, the pure color billet is prepared from the following components by weight: 16-18 parts of potash feldspar, 3-5 parts of potassium feldspar, 12-14 parts of super white stone particles, 1-3 parts of strong plastic sand, selected 20-24 parts of sand, 15-18 parts of kaolin, 2-4 parts of high aluminum powder, 3-5 parts of high clay, 6-8 ...

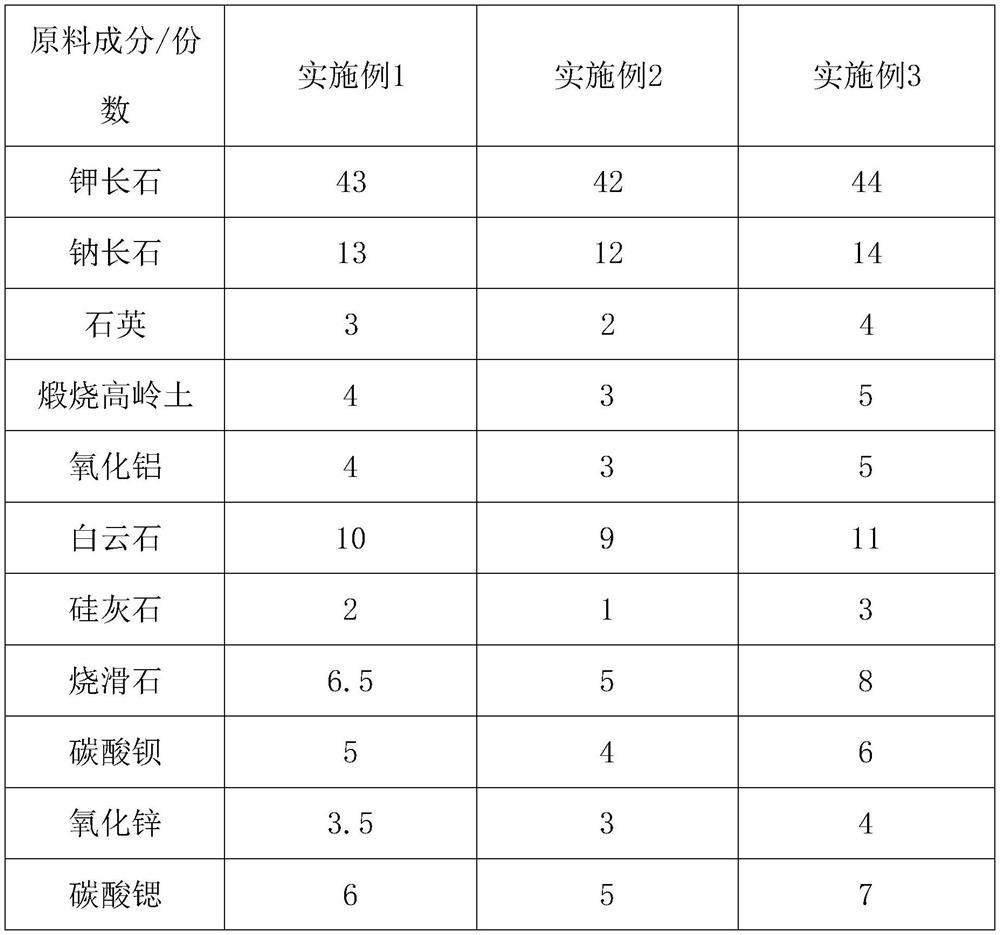

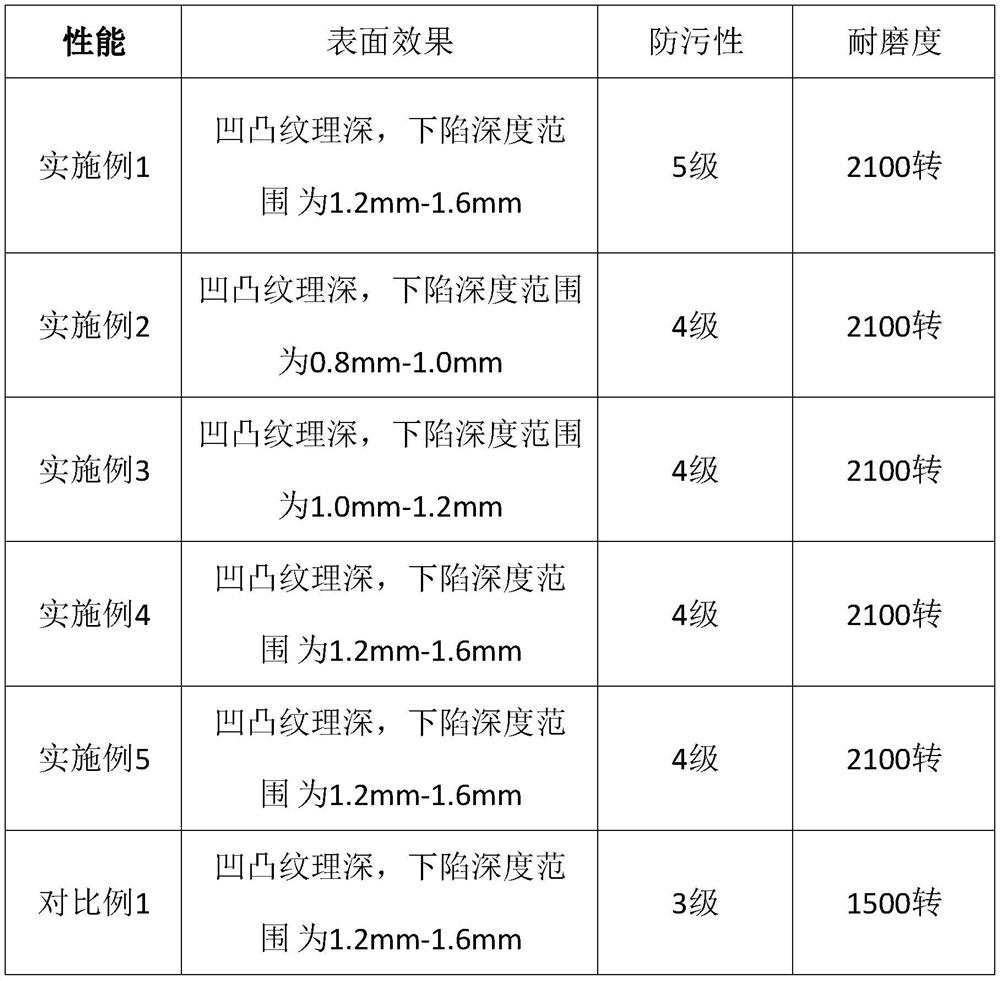

Embodiment 1-5

[0081] A preparation method of a terrazzo-like ceramic plate with concave-convex texture, comprising the steps of:

[0082] (1) Body forming

[0083] Press and form the green body powder into a ceramic green body; transport the formed green body to a drying kiln for drying; after the green body passes through the drying kiln, spray digital surface glaze ink directly; in this step, the green body powder It is a pure color blank. Among them, the pure color billet is prepared from the following components by weight: 17 parts of potassium sodium stone, 4 parts of potassium feldspar, 13 parts of super white stone, 2 parts of strong plastic sand, 23 parts of selected sand, 16 parts of kaolin, 3 parts of high alumina powder, 4 parts of high clay, 7 parts of Fubaisha, 12 parts of high white kaolin, 4.5 parts of billet black material, 0.6 parts of water glass, 0.2 parts of sodium tripolyphosphate, and 0.15 parts of debonding agent.

[0084] (2) spray digital surface glaze ink

[008...

Embodiment 2

[0105] Compared with Example 1, The difference of embodiment 2 is that the specific gravity of the digital surface glaze adopted in the step (3), the amount of glaze applied are different. Similarly, the specific gravity of the digital surface glaze is 1.45, the fineness of the digital surface glaze is nano-level, and the glaze amount is 610g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com