Single-coating PU (polyurethane) paint with high wear resistance and high hardness and preparation method thereof

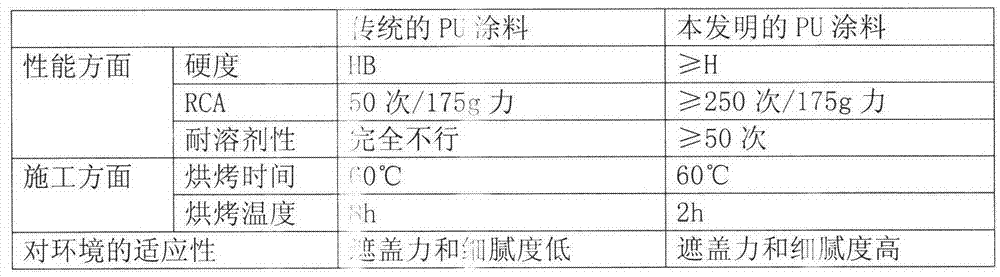

A single-coat, high-hardness technology, applied in the field of coatings, can solve the problems of high production cost, poor wear resistance, and low hardness, and achieve the effects of improving friction performance, avoiding easy cracking, and improving wear resistance and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A single-coat PU coating with high wear resistance and high hardness, the preparation method of which is as follows:

[0028] (1) Weigh 20 parts of Dongsheng AA-2450 and 50 parts of butyl acetate, and add 30 parts of 3M G-100 while stirring to fully stir, and then add the mixture to a sand mill for ultra-fine grinding until The scraper reaches a particle size of less than 10 μm and is made into a semi-finished product for later use;

[0029] (2) Put the semi-finished products obtained in step (1), 1.5 parts of ZF-241.5 parts of Gifu, Japan, 3.6 parts of CAB381-206, and 0.072 parts of BYK3060, into a container together, stir evenly and set aside;

[0030] (3) in the semi-finished product obtained in step (2), add aluminum silver paste, color paste soaked with butyl acetate, mechanically stir, and stirring speed is 500rmp, obtains single coating PU coating;

[0031] (4) Weigh 74 parts of curing agent mixed with BAYER's HDI curing agent and DIC's fluororesin K705 in a mas...

Embodiment 2

[0034] (1) Weigh 20 parts of Dongsheng AA-2450 and 50 parts of butyl acetate, and add 30 parts of 3M G-100 while stirring to fully stir, and then add the mixture to a sand mill for ultra-fine grinding until The scraper reaches a particle size of less than 10 μm and is made into a semi-finished product for later use;

[0035] (2) Put the semi-finished products obtained in step (1), 1.6 parts of ZF-241.6 parts of Gifu, Japan, 3.8 parts of CAB381-203.8 parts, and 0.11 parts of BYK3060 into a container together, stir evenly and set aside;

[0036] (3) in the semi-finished product obtained in step (2), add aluminum silver paste, color paste soaked with butyl acetate, mechanically stir, and stirring speed is 500rmp, obtains single coating PU coating;

[0037] (4) Weigh 74 parts of curing agent mixed with BAYER's HDI curing agent and DIC's fluororesin K705 in a mass ratio of 5:1 in a container, add 26 parts of butyl acetate solvent while stirring, and finish adding Then continue to ...

Embodiment 3

[0040] (1) Weigh 20 parts of Dongsheng AA-2450 and 50 parts of butyl acetate, and add 30 parts of 3M G-100 while stirring to fully stir, and then add the mixture to a sand mill for ultra-fine grinding until The scraper reaches a particle size of less than 10 μm and is made into a semi-finished product for later use;

[0041] (2) Put the semi-finished products obtained in step (1), 1.7 parts of ZF-241.7 parts of Gifu, Japan, 0.14 parts of CAB381-204 parts, and 0.14 parts of BYK306 into the container together, stir evenly and set aside;

[0042] (3) in the semi-finished product obtained in step (2), add aluminum silver paste, color paste soaked with butyl acetate, mechanically stir, and stirring speed is 500rmp, obtains single coating PU coating;

[0043] (4) Weigh 74 parts of curing agent mixed with BAYER's HDI curing agent and DIC's fluororesin K705 in a mass ratio of 5:1 in a container, add 26 parts of butyl acetate solvent while stirring, and finish adding Then continue to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com