Polyurethane prepolymer, preparation method thereof and polyurethane product

A polyurethane prepolymer and diisocyanate technology, which is applied in the field of polymer material preparation, can solve the problem of high content of free diphenylmethane diisocyanate, and achieve the effects of excellent environmental protection performance, clear process, and prevention of cost increase and deterioration risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

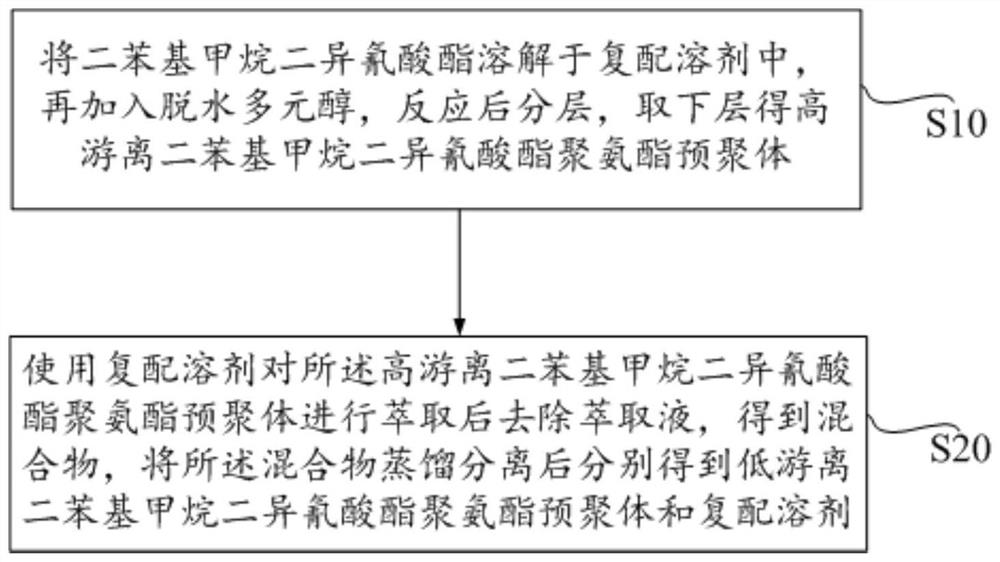

[0035] Please refer to figure 1 , the preparation method of low free diphenylmethane diisocyanate polyurethane prepolymer comprises the following steps:

[0036] Step S10, dissolving diphenylmethane diisocyanate in the compounding solvent, adding anhydrous polyol, layering after reaction, and removing the lower layer to obtain a high-free diphenylmethane diisocyanate polyurethane prepolymer.

[0037] It should be noted that diphenylmethane diisocyanate, the molecular formula is C 15 h 10 N 2 o 2 , molecular weight 250.25, including 4,4'-MDI, 2,4'-MDI and 2,2'-MDI three isomers, of which 4,4'-MDI has the most content.

[0038] The dehydrated polyols include long-chain polyester polyols or long-chain polyether polyols, long-chain polyester polyols include conventional polyester polyols, polycaprolactone polyols or polycarbonate diols, conventional polyester polyols Alcohols are mainly composed of polyhydric alcohols including ethylene glycol, diethylene glycol, 1,2-propylen...

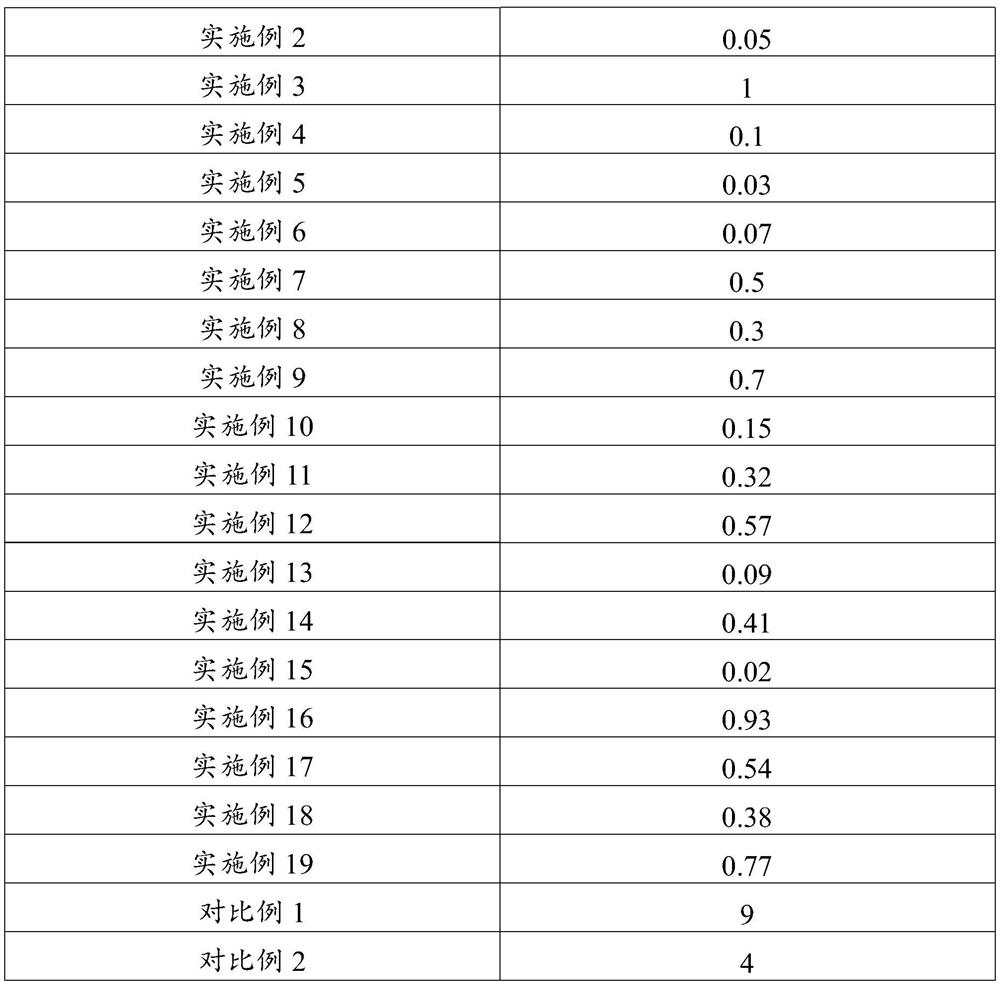

Embodiment 1

[0062] (1) Add dehydrated polyol dropwise to the compound solvent in which diphenylmethane diisocyanate is dissolved at 100°C under stirring condition for 2.5 hours, and continue stirring after dropping until no more deposits are added , Remove the layer to get high free diphenylmethane diisocyanate polyurethane prepolymer.

[0063] (2) Collect the upper layer solution in step (1), and distill and separate the upper layer solution to obtain the compound solvent and diphenylmethane diisocyanate, and the distillation temperature is 85°C.

[0064] (3) At 60°C, inject the high free diphenylmethane diisocyanate polyurethane prepolymer into the tower from the top of the extraction tower, inject the compound solvent into the tower from the bottom of the extraction tower, stir and mix, and remove the extracted liquid to obtain a mixture, and the mixture is distilled and separated to obtain a low-free diphenylmethane diisocyanate polyurethane prepolymer and a compound solvent respectiv...

Embodiment 2

[0068] (1) Add dehydrated polyol dropwise to the compound solvent in which diphenylmethane diisocyanate is dissolved at 60°C under stirring conditions for 3 hours, and continue stirring after dropping until no more deposits are added. Take off the layer to get high free diphenylmethane diisocyanate polyurethane prepolymer.

[0069] (2) Collect the upper layer solution in step (1), and distill and separate the upper layer solution to obtain the compound solvent and diphenylmethane diisocyanate, and the distillation temperature is 80°C.

[0070] (3) At 100°C, inject the high free diphenylmethane diisocyanate polyurethane prepolymer into the tower from the top of the extraction tower, inject the compound solvent into the tower from the bottom of the extraction tower, stir and mix, and remove the extracted liquid to obtain a mixture, and the mixture is distilled and separated to obtain a low-free diphenylmethane diisocyanate polyurethane prepolymer and a compound solvent respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com