Construction technology of inclined supporting piles for soft soil base enclosure

A technology of oblique support and construction technology, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of high cost of foundation pit support technology and inconvenient construction, and achieve barrier-free excavation and structural construction, Save the construction period and reduce the effect of supporting foundation pit excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The contents of the present invention will be further described below with reference to the accompanying drawings and examples:

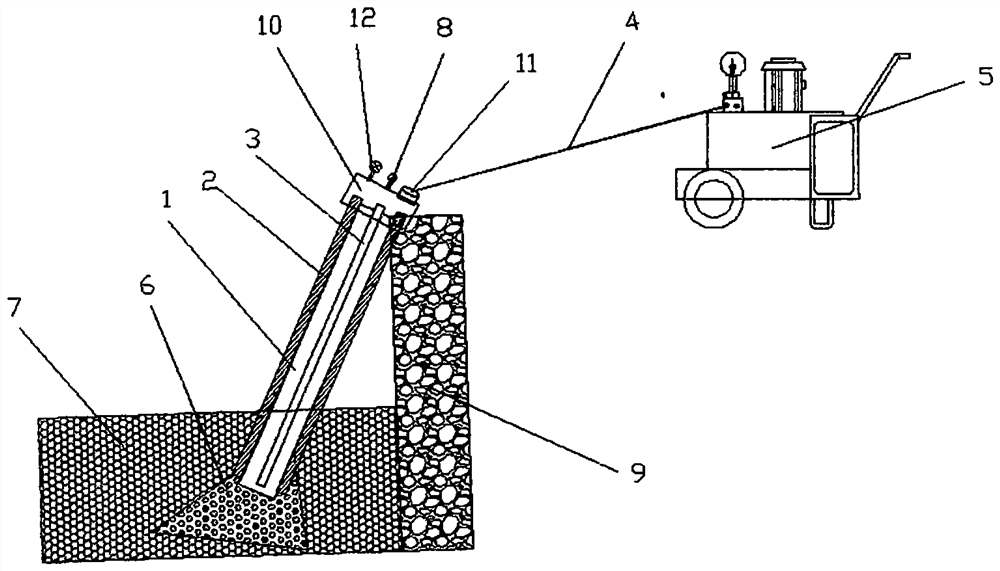

[0028] As shown in the figure, it is shown as a schematic schematic of the construction principle of oblique support, including supporting steel tube 1, grouting tube 2, exhaust pipe 3, high pressure grouting tube 4, grouting machine 5, hard solid structure 6, ground soil layer 7 , Pressure table 8, enclosure 9, pile cap 10, grouting hole 11 and exhaust valve 12.

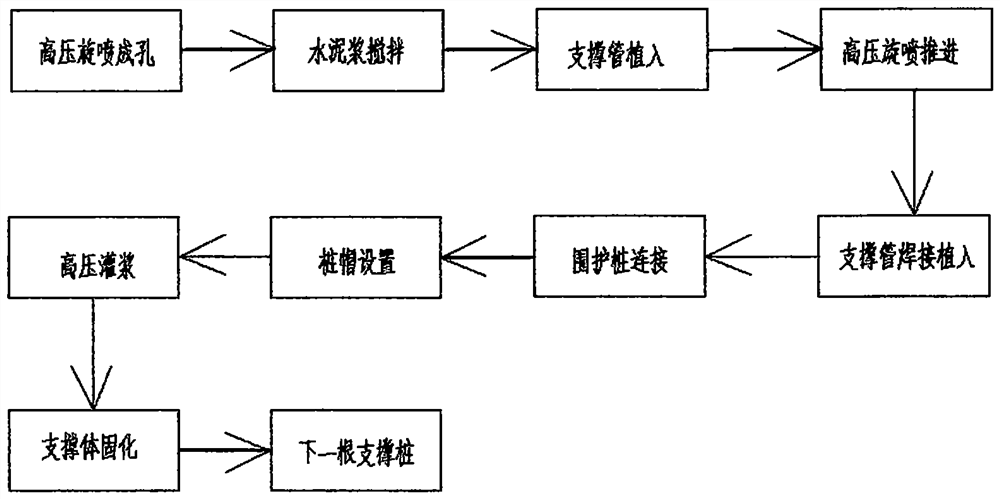

[0029] A construction method for the construction process for the construction process for the oblique support pile of soft soil base enclosure:

[0030] The high-pressure jet tube of the high-pressure spuner pile machine is obliquely obliquely inserted into the cement slurry in a certain angle, so that the oblique support is smoothly implanted, and the support steel tube is obliquely implanted into a hole in a hole in a certain angle. The support steel pipe is segmented, each of which...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap