Anti-swing whole-course speed planning control and positioning system and method for unmanned crown block

A technology of speed planning and speed control, which is applied in control/adjustment system, vehicle position/route/height control, two-dimensional position/course control, etc. The effect of high vehicle running stability, reducing frequent start and stop, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

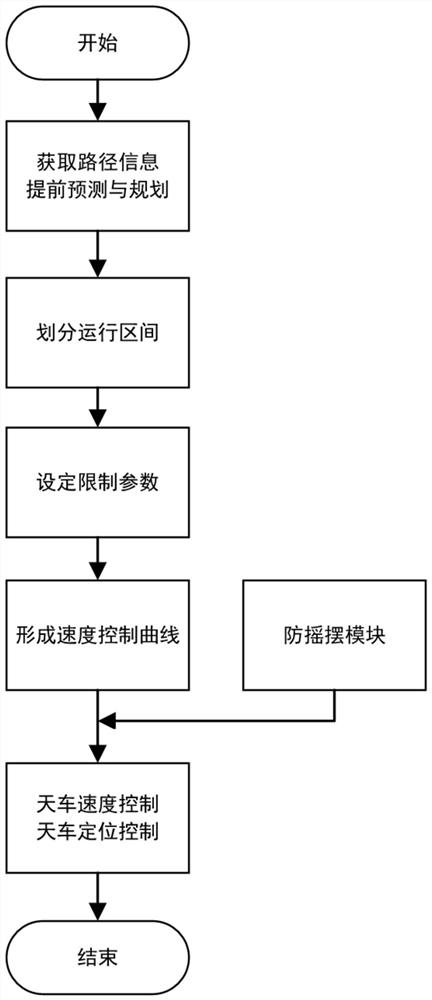

[0043] to combine figure 1 and figure 2 In this embodiment, in order to realize the full speed control and precise positioning of the unmanned crane, its control system mainly includes the crane operation information acquisition unit, the crane path prediction and planning unit, the crane operation interval setting unit, the speed control curve and the optimization unit, anti-sway control unit, crane running speed and positioning control unit.

[0044] When the warehouse management system issues a crane scheduling task, the crane operation information acquisition unit obtains the actual position of the crane and the corresponding avoidance point information. According to the actual position of the crane and the information of the corresponding avoidance point, the path prediction and planning unit of the crane will predict and plan the path in advance, and will issue an alarm for the avoidance point and the target point that are not within the allowed operating area during o...

Embodiment 2

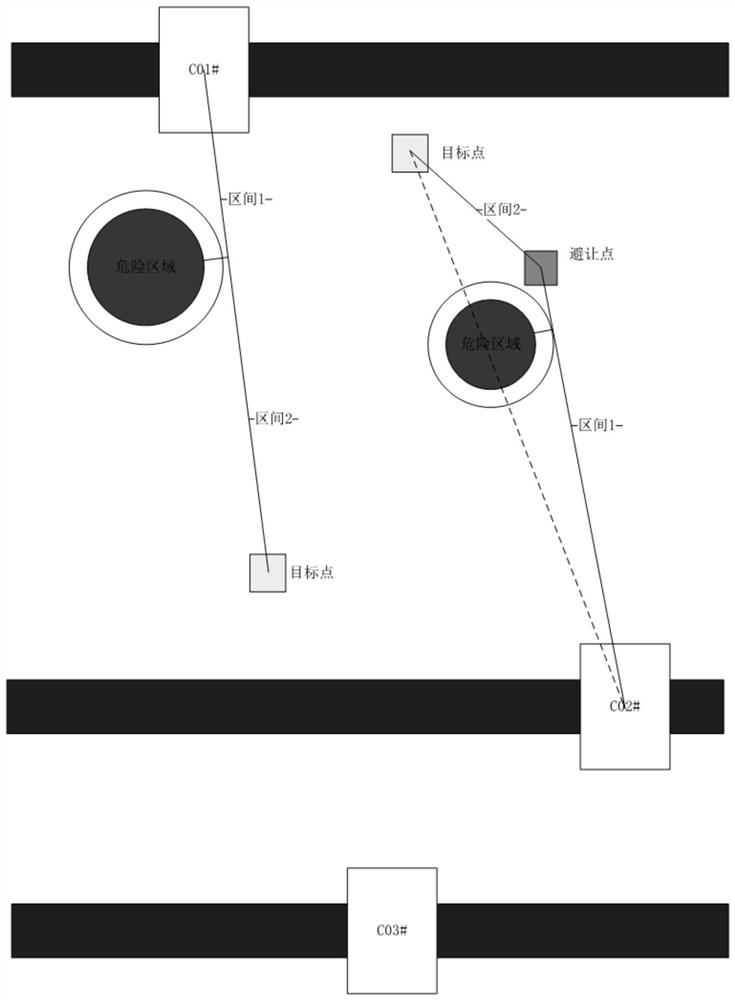

[0058] Before the warehouse area management system issues the crane scheduling task, the crane operation information acquisition unit will obtain the actual operating position information of all cranes in the warehouse area and the corresponding operating status of the cranes in advance, and combine these information with the cranes that are about to perform tasks For the target point to be run, the path and the corresponding avoidance point are generated in advance. The path is directional, and it will directly give an alarm to those who are not within the allowed operating area during the journey.

[0059] The crane operation information acquisition unit acquires the following information:

[0060] 0N# crane actual coordinate information C0N(Xn, Yn) in the storage area

[0061] Crane running status information (1 is running, 0 is stopped)

[0062] If it is in the running state, there is direction information (1 positive direction, 0 negative direction) and the final target ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com