Method and system for automatically controlling feeding

A technology of automatic control and control instructions, which is applied in neural learning methods, image data processing, biological neural network models, etc., can solve problems such as failure to meet industrial needs, damage to the surface of the target, and falling of the target, so as to improve operation Efficiency, implementation of updates, and reduction of operating process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

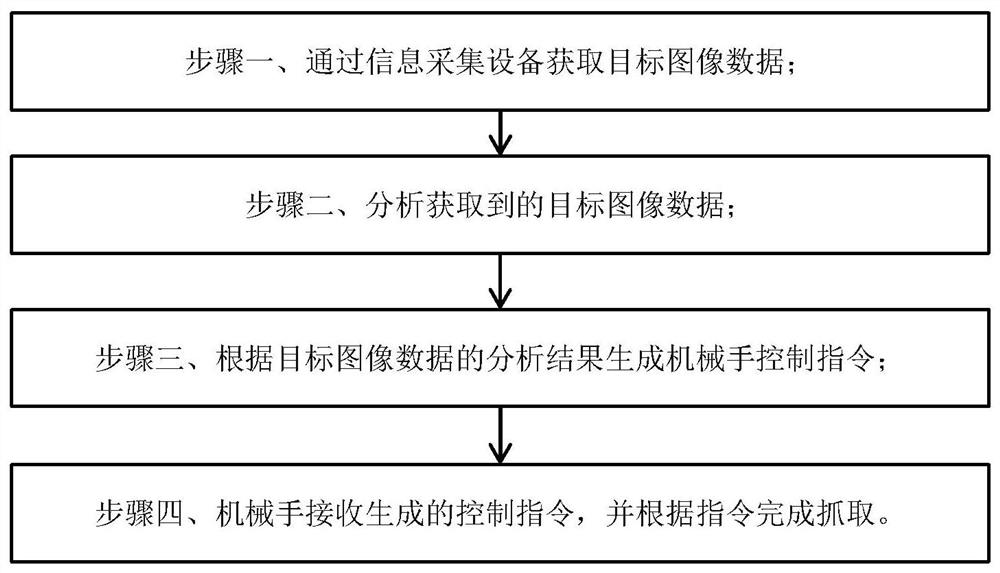

Embodiment 1

[0040] In the industrial operation environment, because the high-risk environment often increases the difficulty of the operation and even endangers the health of the public, therefore, the automatic mechanical gripper that completes the expected operation tasks through programming has emerged as the times require. By replacing manual operations, it not only reduces labor The cost is invested to ensure the safety of workers, and at the same time, the automated mechanical operation also greatly improves the operating efficiency, thereby improving economic benefits. However, by setting the operation method of fixing the grasping frequency, the grasping process of the mechanical grasping process is often inaccurate due to the deviation of the position of the target object, resulting in problems such as falling of the target object or damage to the surface of the target object. , which cannot meet the actual industrial demand. Therefore, this embodiment proposes a method for autom...

Embodiment 2

[0047] In a further embodiment based on the first embodiment, the existing technology often adopts the way of preset mechanical gripper movement path to grasp the target in the process of grasping, but with the position of the target on the conveyor belt Offset, and the placement state is different from the expected, which often leads to the inability of the mechanical gripper to accurately grasp the target, or the phenomenon of falling during the grasping and transportation process due to inaccurate grasping. Therefore, this embodiment adopts real-time analysis of the environmental data of the target object to obtain the actual position of the target object, and then adjusts the movement path of the gripper to increase the gripping accuracy and improve the working efficiency.

[0048] Specifically, since the position of the target on the conveyor belt is likely to be in the same state, in order to reduce a large number of repetitive and redundant analysis operations, the movem...

Embodiment 3

[0060] In a further embodiment based on the first embodiment, during the actual grabbing operation, because defective products or other non-target goods are often mixed in the transport target, in order to improve the operating efficiency of grabbing, this embodiment When performing image data analysis to obtain the actual position of the target, further identify and analyze the type of the target. When the detected item is not the expected target, the grabbing operation will not be performed, thereby improving the grabbing efficiency and reducing the quality of the later stage. check workload.

[0061] Specifically, a target recognition model is constructed to identify target types. In order to better improve the recognition efficiency of the model, after the construction is completed, it is trained by randomly constructing a data set. According to the output results and the verification set For error comparison, weight parameters are adjusted by means of backpropagation. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com