Method for generating inspection task through automatic visual scanning and inspection robot

An inspection robot and inspection task technology, applied in neural learning methods, instruments, manipulators, etc., can solve the problem of high cost of human resources, time and resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

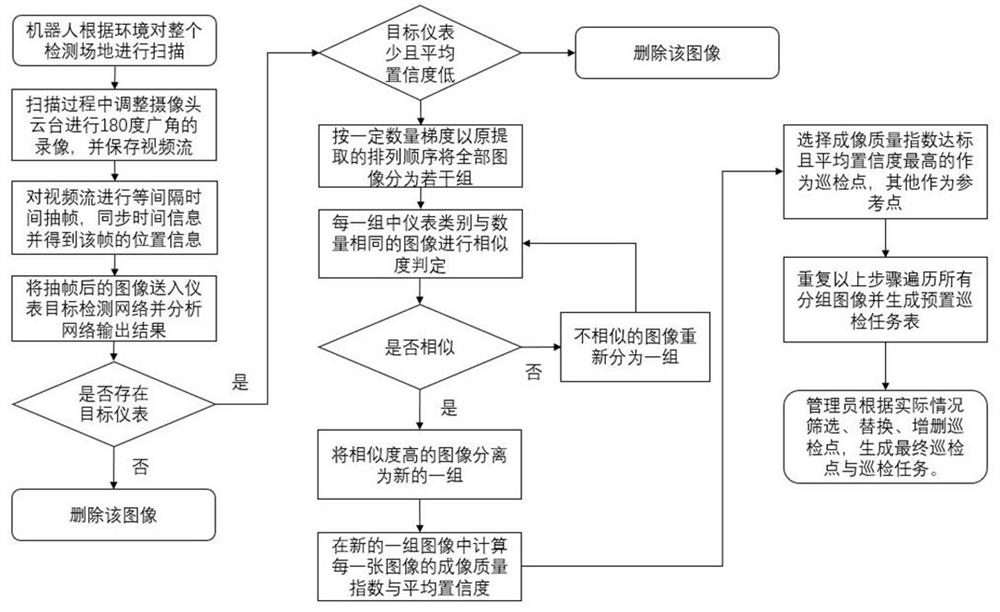

[0051] Start the inspection robot with the method of the present invention, and control the robot from the front end to enter the equipment inspection mode, remote control its initial position to the starting point of the scene, and plan a fixed route on the map page. The robot starts to travel along the planned route, and rotates the gimbal equipped with the visible light camera horizontally at a slow and uniform speed. The range of automatic rotation is [-90°, 90°] in the horizontal direction, that is, mainly on both sides, and [-45°, 45°] in the vertical direction. dropped device. At the same time, video recording is performed, and the position information of the robot and the gimbal is recorded every 0.5s when recording the video.

[0052] Depending on the number of instruments and the size of the site, the duration of the recorded video may be inconsistent. In this embodiment, the duration of the recording is 3 minutes. After the recording is completed, the recorded vide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com