Gate driving method, gate driving circuit and display

A gate drive circuit and gate drive technology, applied in the electronic field, can solve the problems of high cost, complex drive structure, and low resolution, and achieve the effects of small structure size, simplified gate drive structure, and low resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

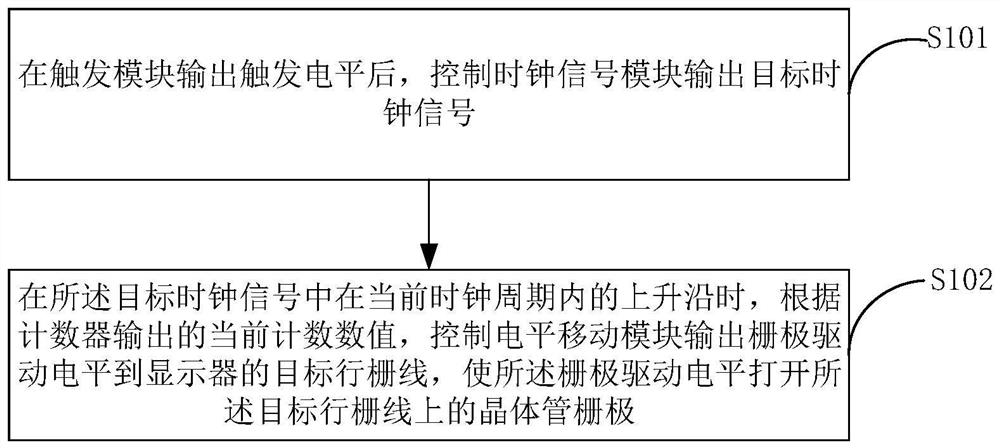

[0033] figure 1 Shown is a schematic flowchart of a gate driving method provided by an embodiment of the present invention, as shown in figure 1 As shown, the gate driving method specifically includes the following steps:

[0034] Step S101, after the trigger module outputs the trigger level, control the clock signal module to output the target clock signal.

[0035] In this embodiment, after the trigger module outputs the trigger level and before controlling the clock signal module to output the target clock signal, the driving method further includes: obtaining the total number of clock cycles in the clock signal according to the number of row gate lines of the display ; Obtain the clock cycle duty ratio according to the frame rate of the display; make the clock signal module generate the target clock signal according to the total number of clock cycles and the clock cycle duty ratio.

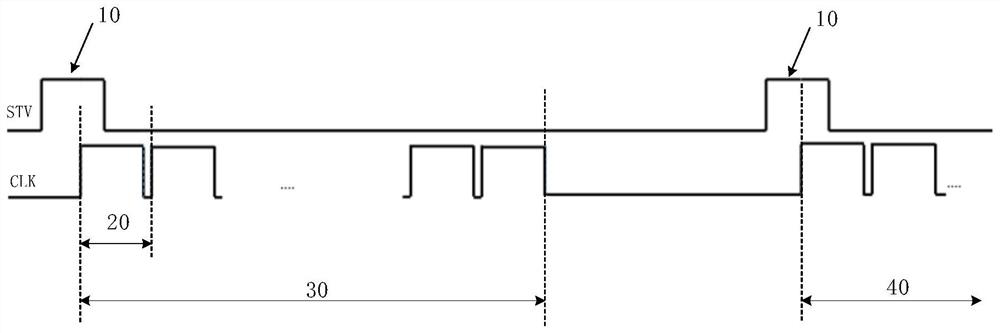

[0036] It should be noted that, if figure 2As shown, the output of the trigger module...

Embodiment 2

[0048] In this embodiment, when the gate drive circuit includes at least two level shifting modules, the drive method further includes:

[0049] On the falling edge of the last clock cycle of the first target clock signal, the clock signal module is controlled to output a second target clock signal, so that the target level shift module performs gate driving according to the second target clock signal; wherein, The first target clock signal is the target clock signal output by the clock signal module at the current clock signal port, and the second target clock signal is the target clock signal output by the next clock output port of the current clock output port, The target level shifting module is a level shifting module connected to the second target clock signal output port.

[0050] It should be noted that when the number of output terminals of the level shifting module is less than the number of row gate lines of the display, multiple level shifting modules are required ...

Embodiment 3

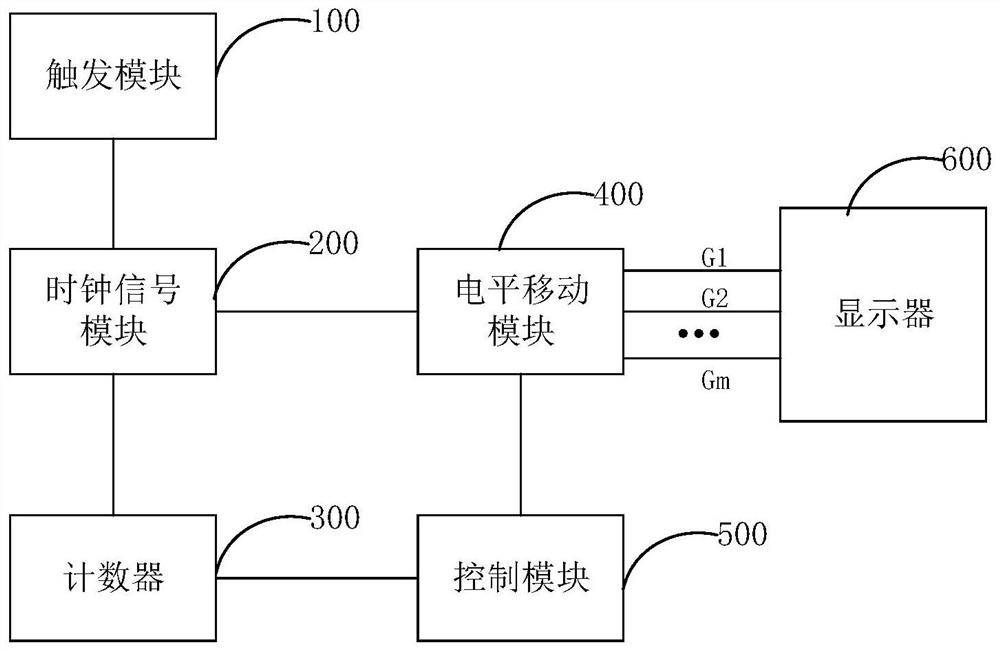

[0056] image 3 Shown is a schematic structural diagram of a gate drive circuit provided by an embodiment of the present invention; image 3 As shown, the gate drive circuit includes:

[0057] A trigger module 100, configured to output a trigger level;

[0058] A clock signal module 200, configured to output a target clock signal;

[0059] The counter 300 is configured to start counting on the rising edge of the first clock cycle in the target clock signal, and clear to zero on the falling edge of the last clock cycle in the target clock signal;

[0060] Level shifting module 400, the input end of level shifting module 400 is connected with described clock signal module 200, a plurality of output ends of described level shifting module 400 are respectively connected with a plurality of row gate lines of display 600 one by one, with To sequentially output the gate drive level to each row gate line of the display, so that the gate drive level sequentially turns on the transis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com