Two-dimensional metal oxide single-layer nanosheet for water evaporation power generation

A technology of oxides and nanosheets, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, which can solve the problem of weak interaction force, low efficiency of water evaporation and electricity generation, affecting the voltage of water evaporation and electricity generation. performance and other issues, to achieve the effects of high surface potential, improved water evaporation power generation performance, and excellent open circuit voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

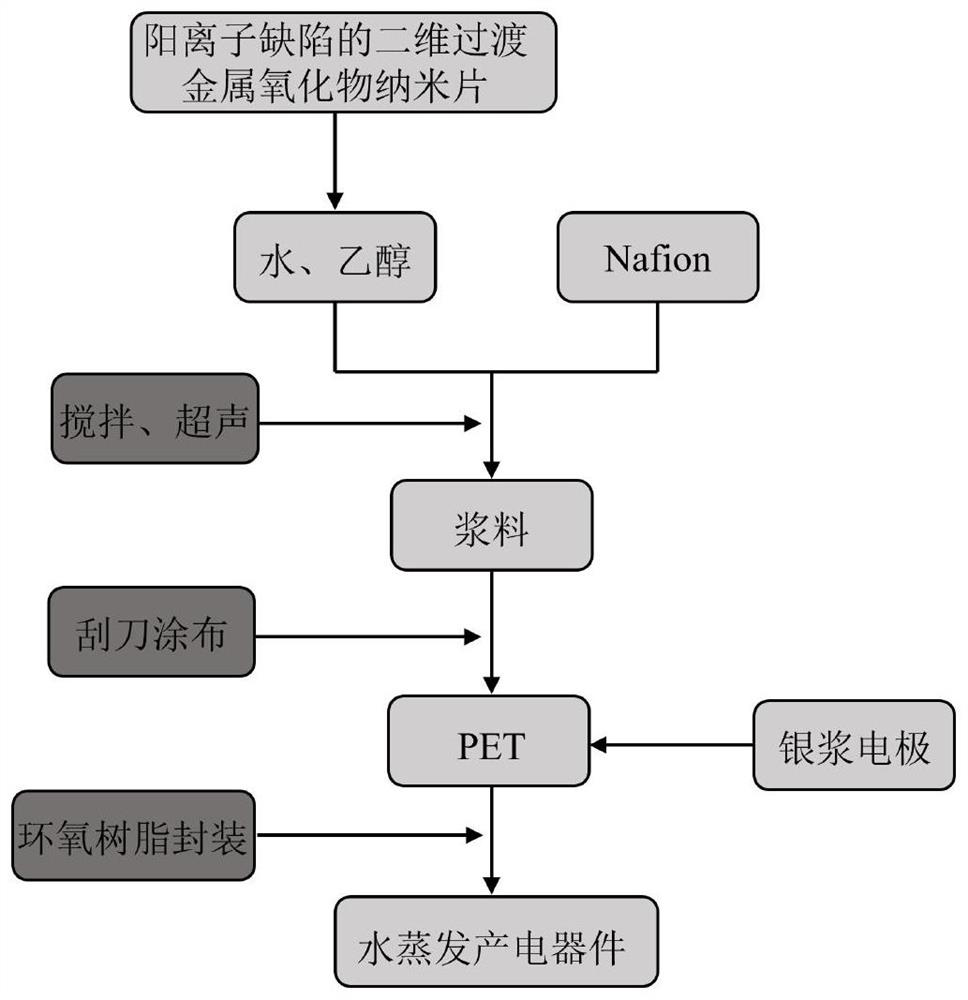

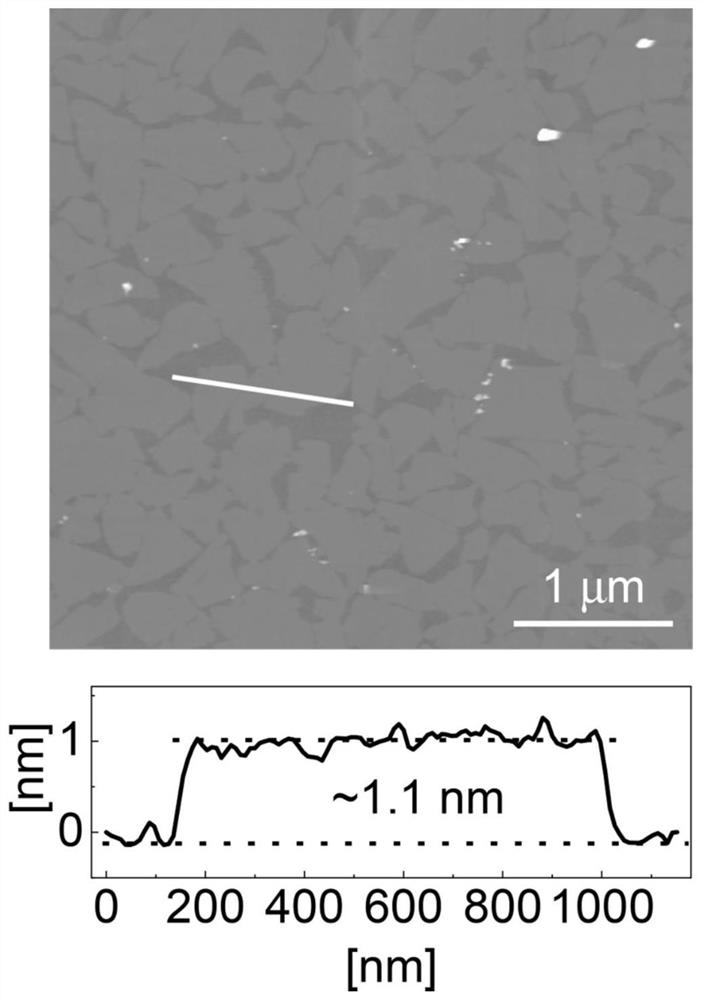

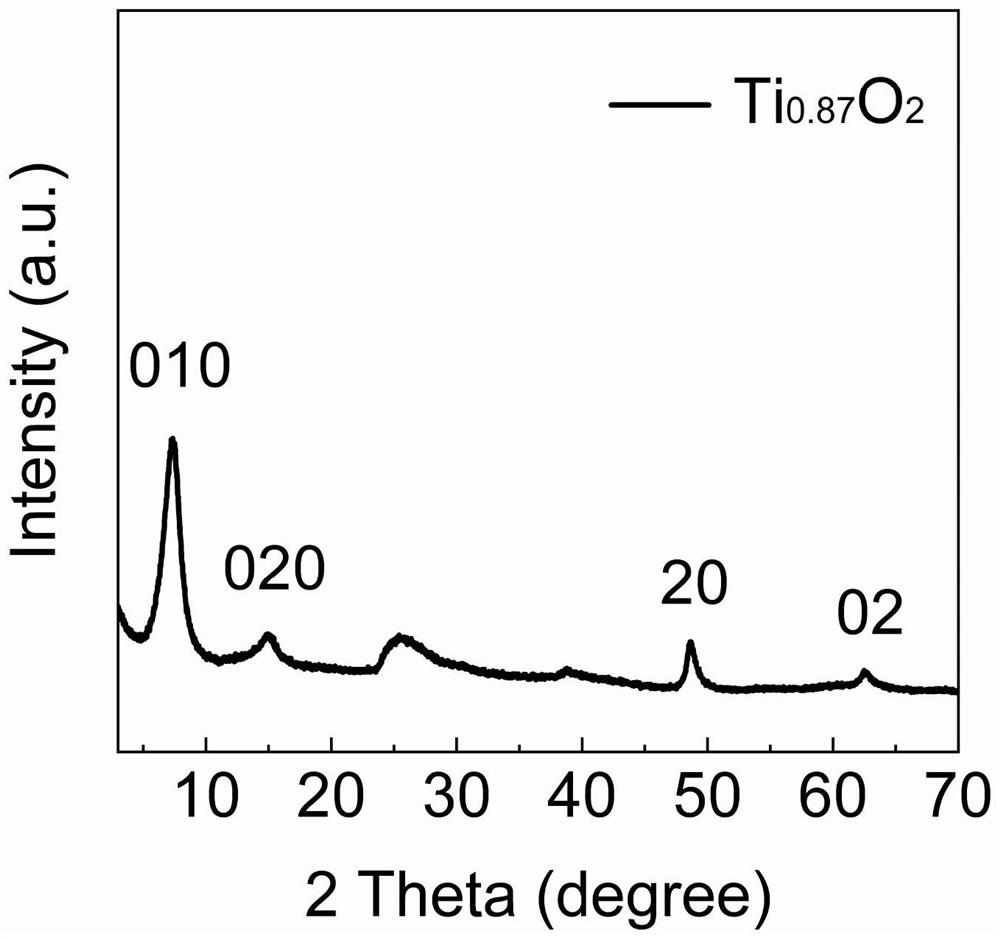

[0042] (1) Weigh 3.07 g K 2 CO 3 , 0.55 g LiCO 3 and 7.60 g Ti 2 O, mixed and ground for 30 min, calcined at 800 °C for 1 h, and the obtained solid was ground again for 30 min, and then calcined at 1000 °C for 20 h to obtain the product K 0.8 Ti 1.73 Li 0.27 o 4 . followed by 4 g K 0.8 Ti 1.73 Li 0.27 o 4 Stir in 500 mL of 1 mol / L HCl solution at room temperature for 3 days, and replace the HCl solution every day to obtain H 1.07 Ti 1.73 o 4 ·H 2 O. Wash the H several times with distilled water 1.07 Ti1.73 o 4 ·H 2 After O to neutrality, filter and dry at room temperature. 2 g H 1.07 Ti 1.73 o 4 ·H 2 After O was mixed with 500 mL TBAOH solution and shaken for 14 days, 1 mol / L HCl solution was added to flocculate, and washed repeatedly with deionized water until neutral, and freeze-dried to obtain Ti 0.87 o 2 .

[0043] (2) Weigh 150 mg Ti 0.87 o 2 and 20 μL Nafion were dissolved in a mixed solution of 1.0 mL deionized water and 33.32 μL ethanol, stir...

Embodiment 2

[0055] (1) Weigh 4.6 g Cs 2 CO 3 and 5.98 g Ti 2 O, mixed and ground for 30 min, calcined at 800 °C for 20 h, and the obtained solid was ground again for 30 min, and then calcined at 800 °C for 20 h to obtain the product Cs 0.7 Ti 1.825 o 4 . 5 gCs 0.7 Ti 1.825 o 4 Stir in 200 mL of 1 mol / L HCl solution at room temperature for 3 days, and replace the HCl solution every day to obtain H 0.7 Ti 1.825 o 4 ·H 2 O. Wash the H several times with distilled water 0.7 Ti 1.825 o 4 ·H 2 After O to neutrality, filter and dry at room temperature. 2 gH 0.7 Ti 1.825 o 4 ·H 2 O was mixed and shaken with 500 mL TBAOH solution for 14 days, then 1 mol / L HCl solution was added to flocculate, and washed repeatedly with deionized water until neutral, and freeze-dried to obtain Ti 0.91 o 2 .

[0056] Other steps are with embodiment 1, with Ti 0.91 o 2 The samples were used for water evaporation to generate electricity.

[0057] Figure 8 For adopting the Ti that embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com