Preparation method of hydrophilic pigment

A hydrophilic and pigment technology, applied in the field of pigments, can solve the problems of easy agglomeration and fast sedimentation, and achieve the effect of improving dispersion stability, increasing potential, and solving poor dispersion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

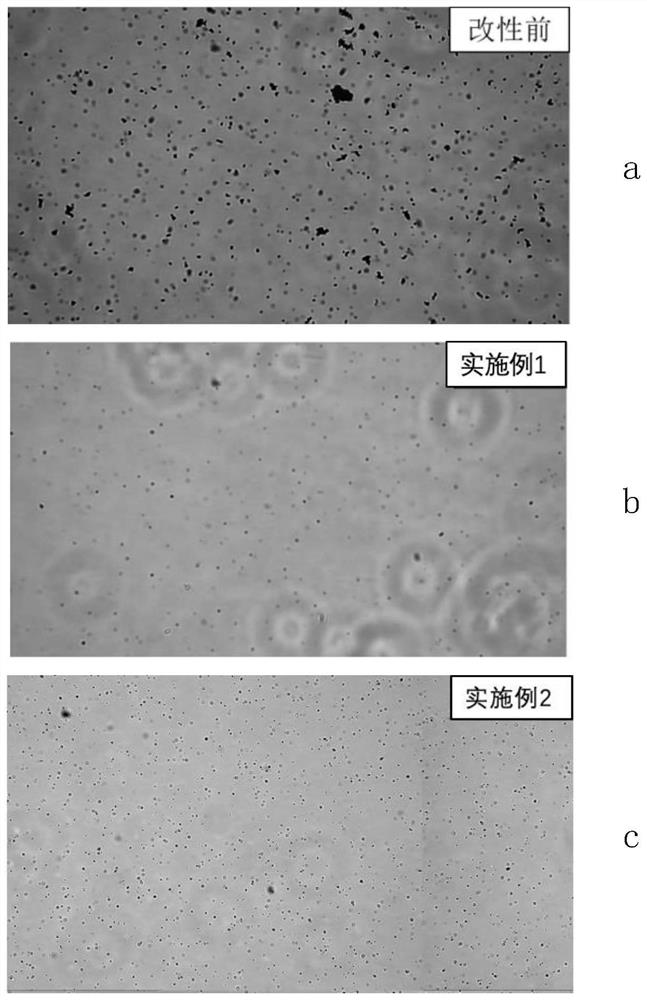

Embodiment 1

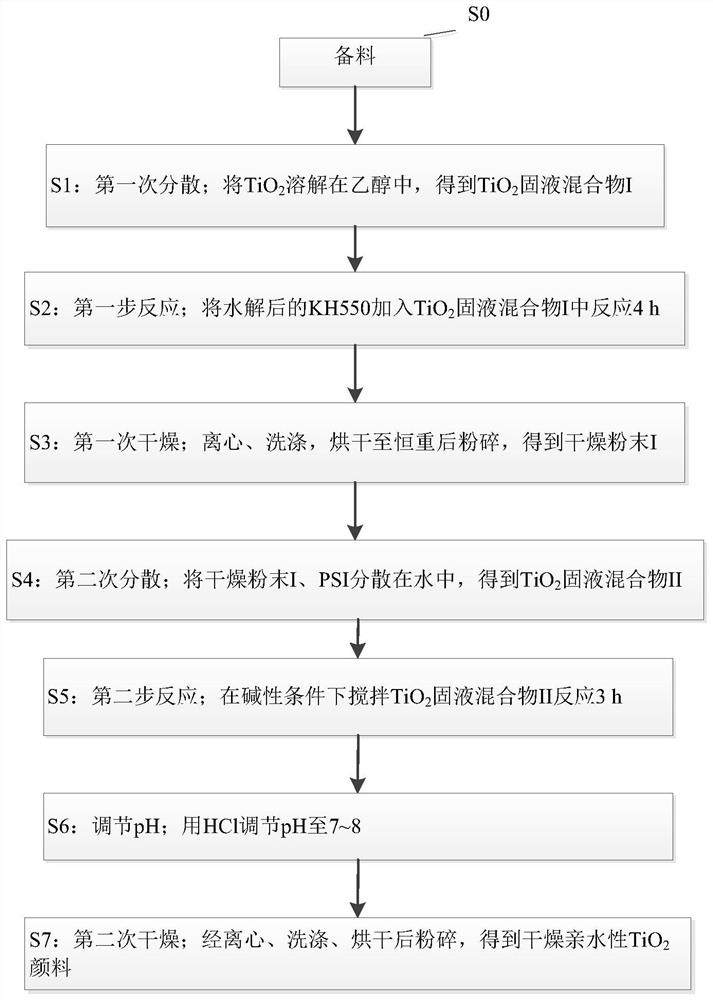

[0049] The present embodiment is to pigment TiO 2 Make modifications. as attached figure 1 Shown, is the hydrophilic pigment TiO 2 The preparation process flow chart specifically comprises the following steps:

[0050] S0: material preparation.

[0051] S1: the first dispersion; 5g TiO 2 and 30mL of absolute ethanol were stirred evenly to obtain TiO 2 Solid-liquid mixture I.

[0052] S2: The first step reaction; hydrolyze 0.5g 3-aminopropyltriethoxysilane (KH550) in 5mL 80% ethanol solution for 5min, then add the above TiO 2 In the solid-liquid mixture I, stir, condense and reflux for 4h.

[0053] S3: drying for the first time; centrifugation, washing, drying to a constant weight, and pulverization to obtain dry powder I.

[0054] S4: Second dispersion; mix 1.5g PSI with the above dry powder I and add to 100mL water and stir evenly to obtain TiO 2 Solid-Liquid Mixture II.

[0055] S5: The second step reaction; add 1.5g NaOH to the above TiO 2 In the solid-liquid mixtu...

Embodiment 2

[0064] This embodiment continues to pigment TiO 2 Make modifications. Specifically, take 5g TiO 2 , and the TiO 2 and 3-aminopropyltriethoxysilane mass ratio adjusted to 1:0.02, TiO 2 The mass ratio to PSI is adjusted to 1:0.1, and the preparation process and other conditions are the same as in Example 1.

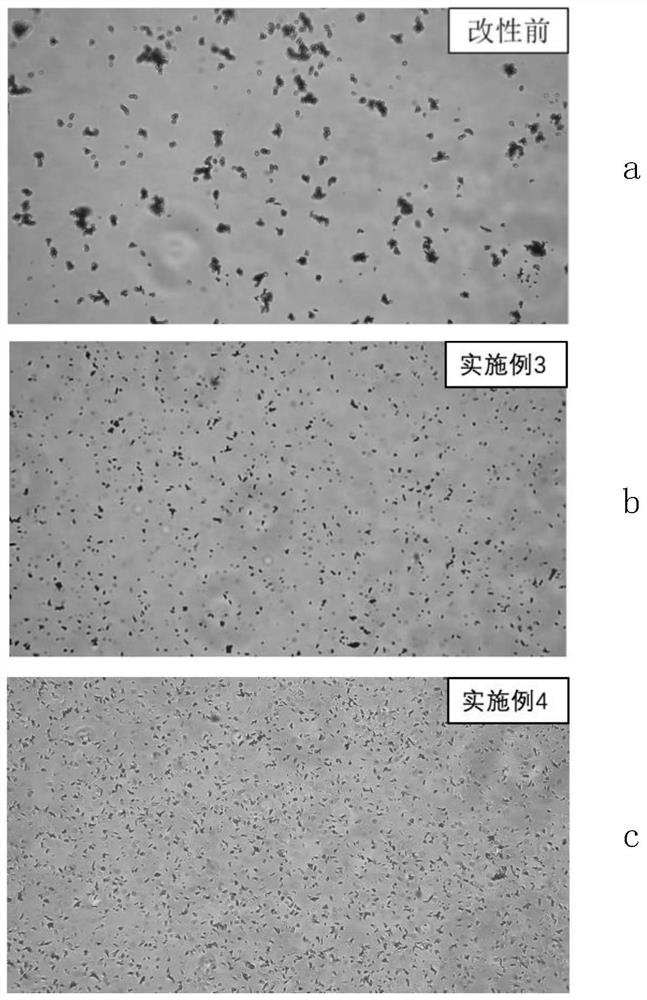

Embodiment 3

[0066] In this embodiment, iron oxide yellow is modified. Specifically include the following steps:

[0067] S0: material preparation.

[0068] S1: Disperse for the first time; stir 5 g of iron oxide yellow and 30 mL of absolute ethanol evenly to obtain iron oxide yellow solid-liquid mixture I.

[0069] S2: The first step reaction: hydrolyze 0.75g of 3-aminopropyltriethoxysilane in 5mL of 80% ethanol solution for 5min, then add it to the above iron oxide yellow solid-liquid mixture I, stir, condense and reflux for 4h.

[0070] S3: drying for the first time; centrifugation, washing, drying to a constant weight, and pulverization to obtain dry powder I.

[0071] S4: second dispersion; mix 2.0g of PSI with the above dry powder I, add to 100mL of water and stir evenly to obtain yellow iron oxide solid-liquid mixture II.

[0072] S5: The second step reaction; add 1.5g NaOH to the above iron oxide yellow solid-liquid mixture II, and stir for 3h.

[0073] S6: adjust the pH; adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com