Dry separation system suitable for separating slack coal

A sorting system and sorting technology, used in solid separation, chemical instruments and methods, grids, etc., can solve the problems of easy clogging of sieve holes, inconvenient cleaning of multi-layer bed surface sieve plates, affecting coal screening, etc. Vibration effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

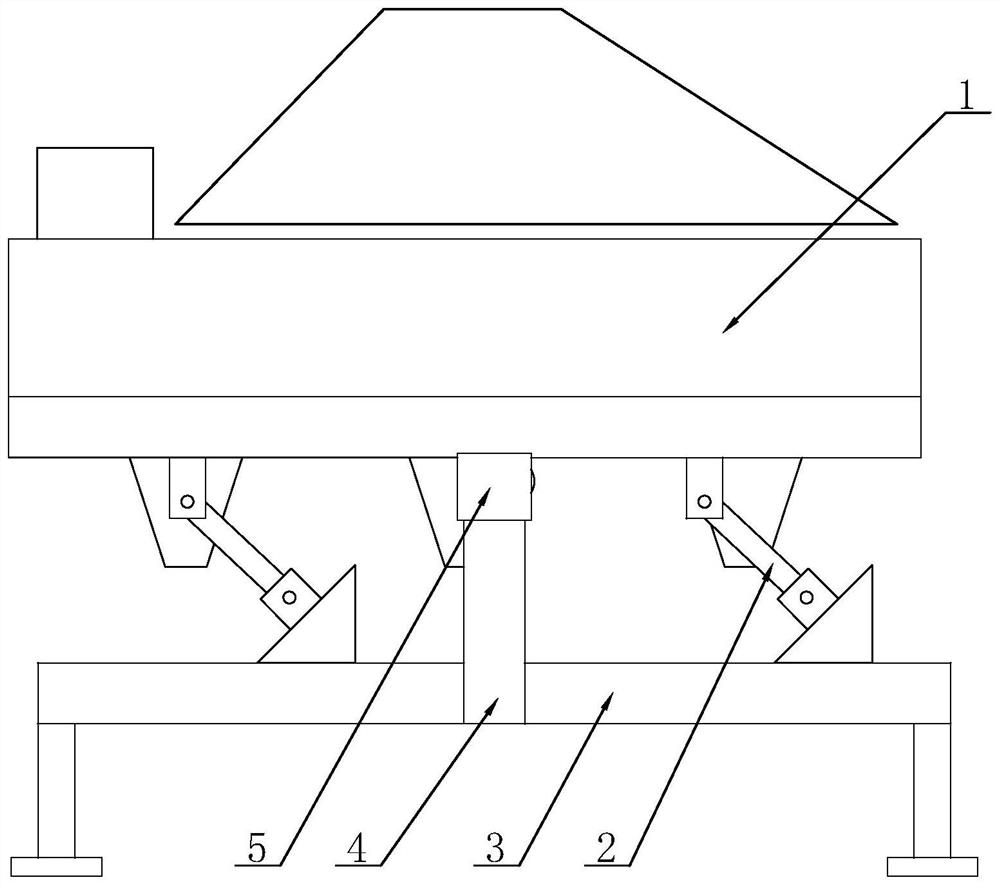

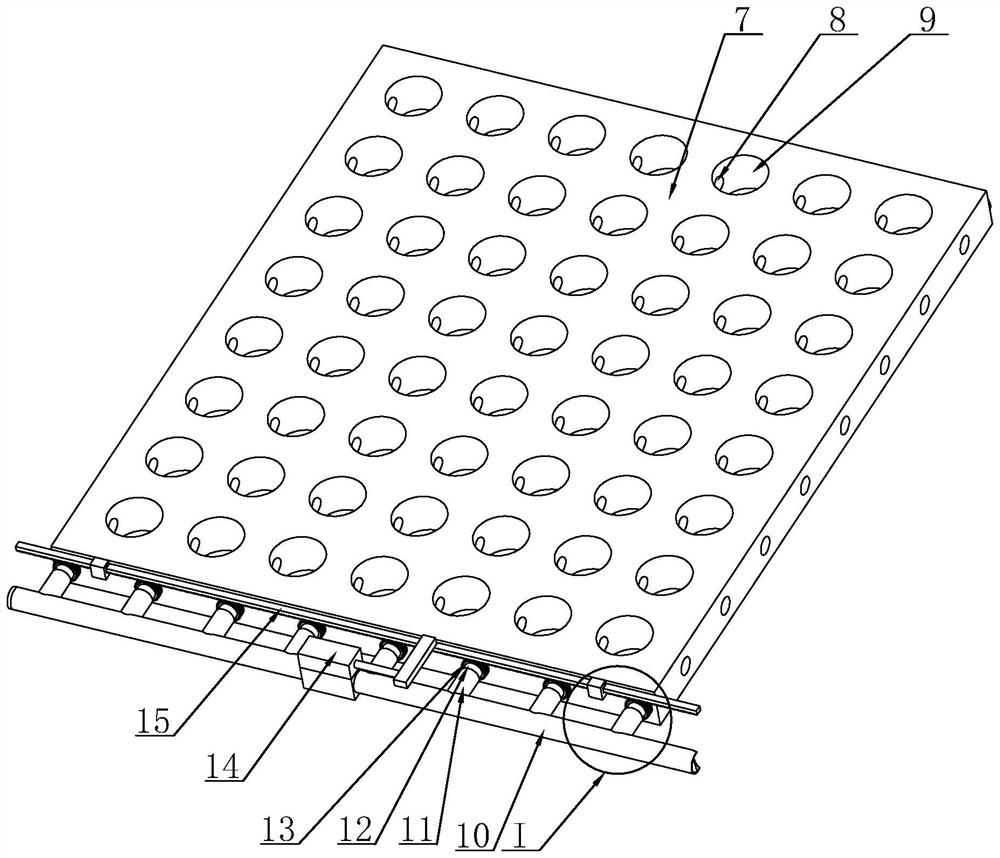

[0037] Such as Figure 1-Figure 8 As shown, a dry separation system suitable for separating fine coal includes a separation bed 1, a base 3 arranged below the separation bed 1, and a number of hinged rods 2 are hinged on the base 3. In this embodiment Among them, there are four hinged rods 2, and the four hinged rods 2 are respectively arranged at the four corners of the base 3. The end of the hinged rods 2 away from the base 3 is hinged to the sorting bed 1, and the base 3 is fixed with a support Seat 4, driving motor 5 is fixed on the supporting seat 4, driving cam 6 is fixed on the rotating shaft of driving motor 5, and driving cam 6 is arranged on the below of sorting bed body 1, and the outer wall of driving cam 6 is connected with the side of sorting bed body 1. The lower side abuts.

[0038]The driving motor 5 drives the driving cam 6 to rotate. Since the driving cam 6 supports the sorting bed 1, the rotation of the driving cam 6 can drive the overall vibration of the ...

Embodiment 2

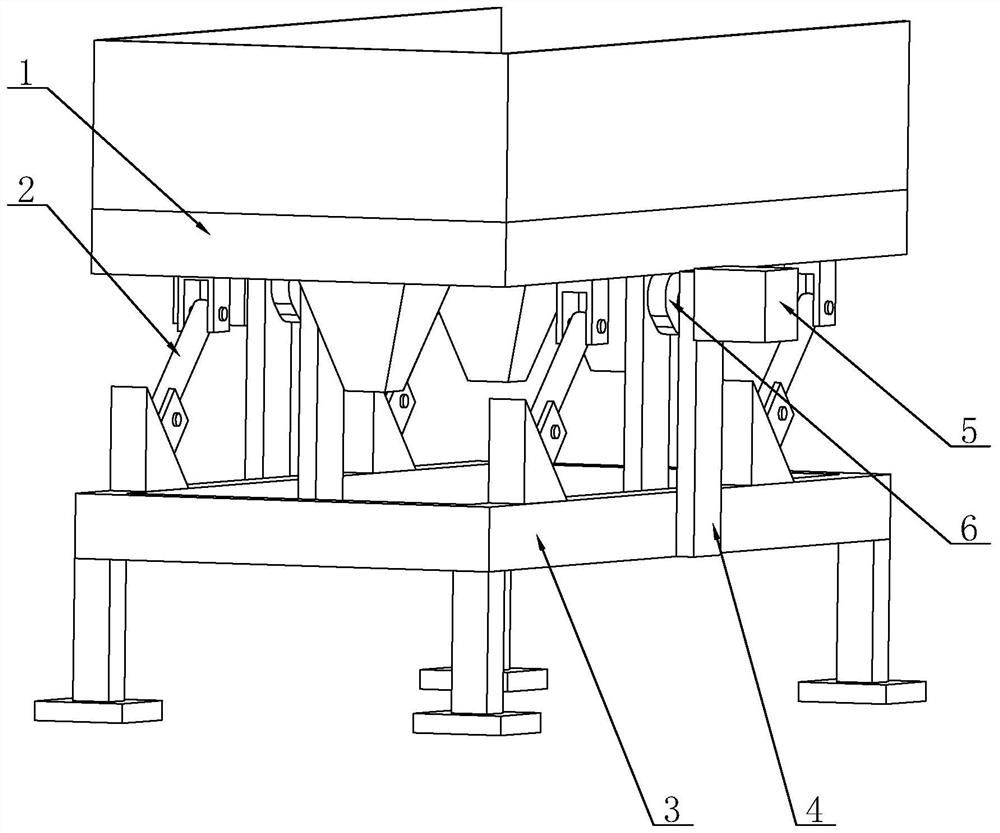

[0047] Such as Figure 9 As shown, the difference between the present embodiment and the first embodiment is that the setting method of the support base 4 is different. There are four support bases 4, and the four support bases 4 are respectively arranged at the four corners of the base 3. A first drive shaft 25 is rotatably connected between the two support bases 4, a second drive shaft 21 is rotatably connected between the two support bases 4 at the back, and two are fixed on the first drive shaft 25 and the second drive shaft 21. One driving cam 6, four driving cams 6 are at the four corners of the sorting bed body 1 respectively, the driving motor 5 drives the first driving shaft 25 to rotate, the driving sprocket 24 is fixed on the first driving shaft 25, the second A driven sprocket 22 is fixed on the driving shaft 21 , and a connecting chain 23 is connected between the driving sprocket 24 and the driven sprocket 22 .

[0048] The driving motor 5 drives the first drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com