Raw material crushing device for plywood processing

A technology for raw material pulverization and plywood, which is used in wood processing appliances, manufacturing tools, etc., can solve the problems of production and processing operations, poor pulverization effect, etc., and achieve the effect of good pulverization effect and sufficient and effective treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

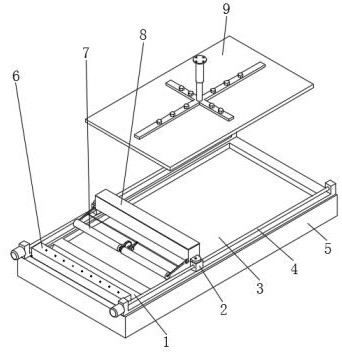

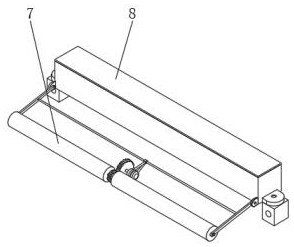

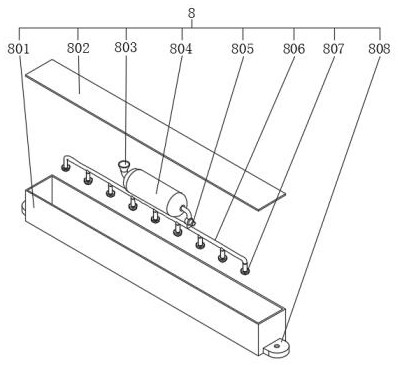

[0025] Such as Figure 3-Figure 4As shown, in this embodiment, in order to carry out the first crushing process to the plywood raw material, the crushing box 2 is fixedly connected to the top surface of the support frame 1, and the top surface of the crushing box 2 is provided with a feed port 7, and the crushing box 2 A group of symmetrical first rotating holes 8 are respectively opened on the walls of the front and rear ends of 2, and the first rotating rod 17 is fixedly installed on the front and rear ends of the first crushing roller 13 and the second crushing roller 14, and the first rotating rod 17 Interspersed and installed in the first rotating hole 8, the outer walls of the first crushing roller 13 and the second crushing roller 14 are fixedly equipped with several crushing knives 15, and staggered knife grooves 16 are formed between adjacent crushing knives 15. The crushing knife 15 on the crushing roller 13 is positioned in the staggered knife groove 16 formed on th...

Embodiment 2

[0027] Such as image 3 and Figure 5 As shown, in this embodiment, in order to carry out secondary processing to the plywood raw material pulverized by the first pulverizing mechanism 4, the pulverizing cylinder 3 is fixedly installed in the middle of the support frame 1 and is located below the pulverizing box 2, and the pulverizing cylinder 3 and The crushing boxes 2 are connected to each other, and the walls of the front and rear ends of the crushing cylinder 3 are respectively provided with second rotating holes 9, and the front and rear ends of the rotating rod 22 are respectively fixedly equipped with second rotating rods 24, and the second rotating rods 24 penetrate Installed in the second rotating hole 9, several crushing plates 23 are fixedly installed on the outer wall of the rotating roller 22, and the outer wall of the crushing plate 23 does not fit the inner wall of the crushing cylinder 3, and the second drive motor 21 is fixed and installed by bolts On the fro...

Embodiment 3

[0029] Such as image 3 and Figure 6 As shown, in this embodiment, in order to filter the plywood raw material after crushing, the filter cartridge 10 is fixedly installed on the bottom end of the crushing cartridge 3, and communicates with the crushing cartridge 3, and the bottom of the filter cartridge 10 A plurality of filter leak holes 11 are provided on the outer wall of the half part, and a connecting port 12 is also provided on the rear end wall of the filter cartridge 10. Fan 26 is fixedly installed on the surface, and the input end of fan 26 is fixedly installed with feed pipe 28, and the other end of feed pipe 28 is fixedly installed on the connection port 12, and the output end of fan 26 is fixedly installed with discharge pipe 27, and The discharge port of the discharge pipe 27 is located above the side of the crushing box 2. After the crushed plywood raw material falls into the filter cartridge 10 from the crushing cylinder 3, the reduced plywood raw material wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com