Automatic cosmetic filling line

An automatic filling and cosmetics technology, which is applied to the safety device of the filling device, packaging, bottle filling, etc., can solve the problems of no positioning mechanism, large manual labor, waste of cosmetics, etc., and achieve reasonable structural design, simple operation, and solution The effect of staff shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

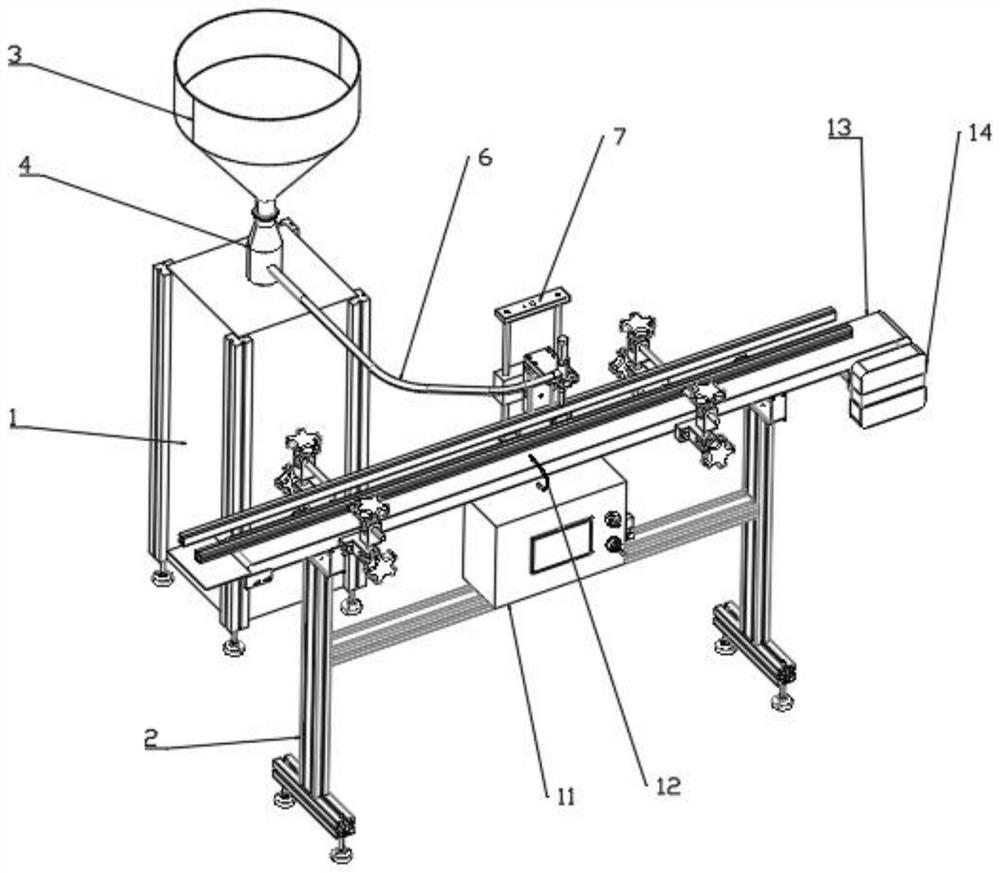

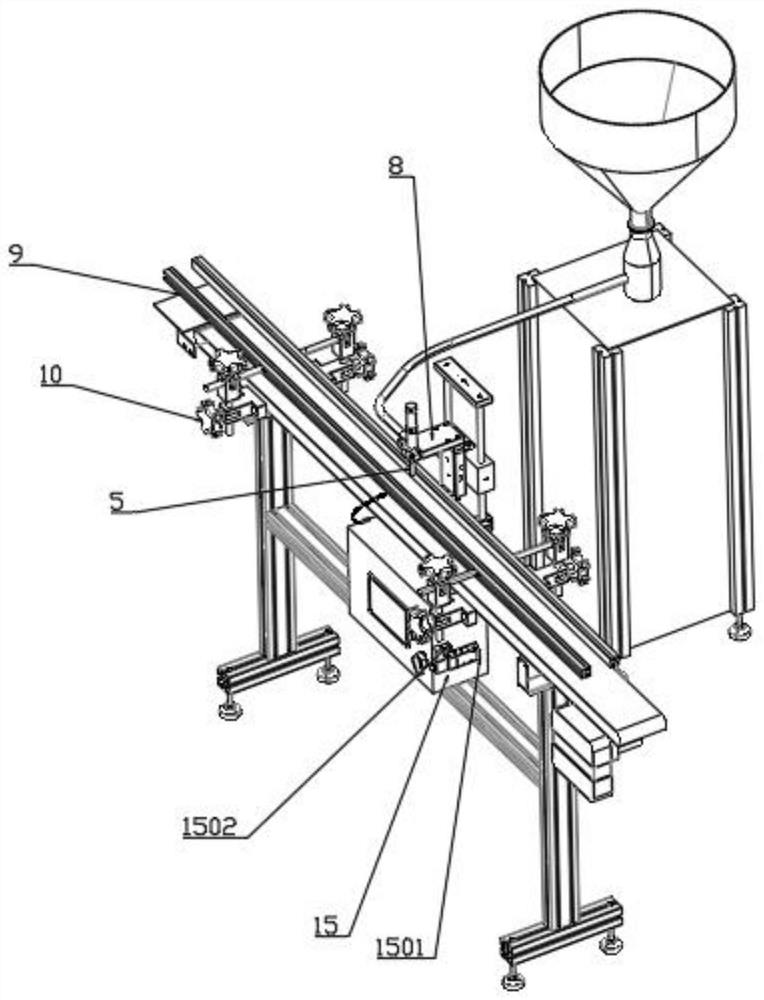

[0011] A cosmetic automatic filling line of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] combined with figure 1 - attached figure 2 , an automatic filling line for cosmetics, including a workbench 1, a work frame 2, a material tank 3, a magnetic pump 4, a filling head 5, a filling tube 6, a mounting frame 7, a sliding device 8, a stop rod 9, and an adjustment device 10. PLC controller 11, optical fiber sensor head 12, conveyor belt 13, transmission power device 14, solenoid valve 15, No. 1 interface 1501, and No. 2 interface 1502. The workbench 1 is provided with a fixedly connected magnetic pump 4, so The outlet of the material tank 3 is fixedly connected with the inlet of the magnetic pump 4, the outlet of the magnetic pump 4 is fixedly connected with the filling pipe 6, and the other end of the filling pipe 6 is provided with a fixedly connected filling head 5. The work frame 2 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com