Long-wave cured wood coating and preparation method thereof

A technology for wood coatings and mixtures, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as non-reaction curing, and achieve simple construction methods, long service life, and improved use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

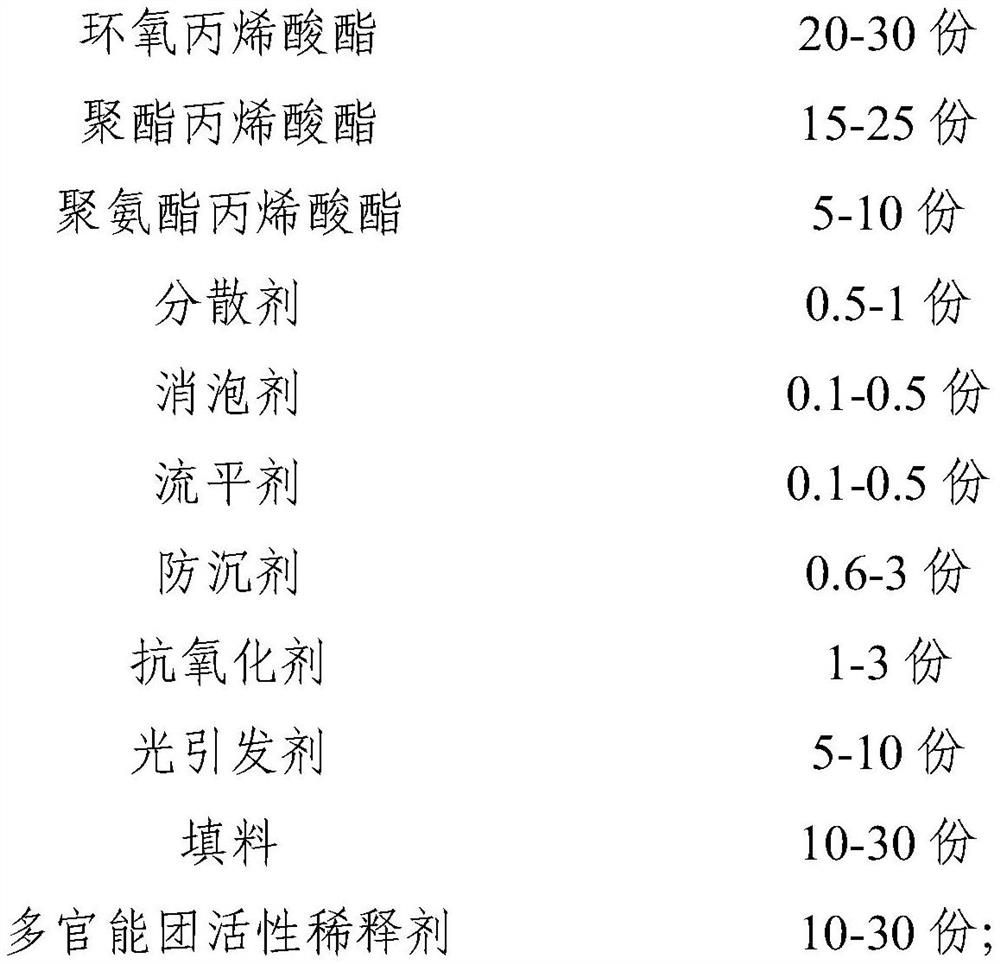

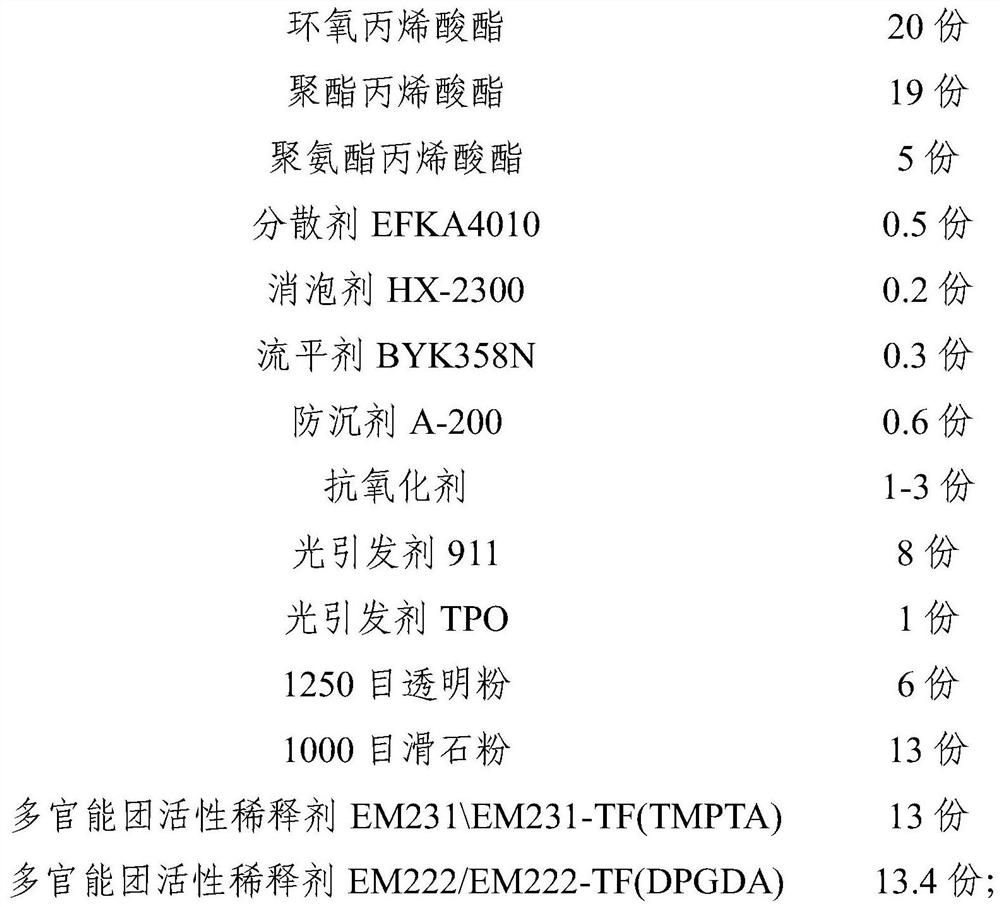

[0054] Present embodiment provides a kind of wood coating, by weight, its formula is as follows:

[0055]

[0056] Its preparation method comprises the following steps:

[0057] (1) Epoxy acrylate, polyester acrylate, polyurethane acrylate and multifunctional reactive diluent EM231\EM231-TF (TMPTA) are dropped into the reactor, stirred at 800r / min for 10min to obtain compound I;

[0058] (2) Stir the mixture I, dispersant, defoamer, leveling agent, antioxidant and photoinitiator at 800r / min for 10min to obtain mixture II;

[0059] (3) Stir the mixture II, 1250-mesh transparent powder, 1000-mesh talcum powder and anti-settling agent for 30 minutes at 1200 r / min to obtain a mixture III with a dispersion fineness of ≤50 μm;

[0060] (4) Stir the mixture III and 4.4 parts of multifunctional reactive diluent EM222 / EM222-TF (DPGDA) at 600r / min for 5min, then add 9 parts of multifunctional reactive diluent EM222 / EM222-TF (DPGDA) Stir at 600r / min for 10min, that is.

Embodiment 2

[0062] The present embodiment provides a wood coating, which comprises the following components in parts by weight:

[0063]

[0064] Its preparation method comprises the following steps:

[0065] (1) Epoxy acrylate, polyester acrylate, polyurethane acrylate and multifunctional reactive diluent EM231\EM231-TF (TMPTA) are dropped into the reactor, stirred at 800r / min for 10min to obtain compound I;

[0066] (2) Stir the mixture I, dispersant, defoamer, leveling agent, antioxidant and photoinitiator at 800r / min for 10min to obtain mixture II;

[0067] (3) Stir the mixture II, 1250-mesh transparent powder, 1000-mesh talcum powder and anti-settling agent for 30 minutes at 1200 r / min to obtain a mixture III with a dispersion fineness of ≤50 μm;

[0068] (4) Stir the mixture III and 1.4 parts of multifunctional reactive diluent EM222 / EM222-TF (DPGDA) at 600r / min for 5min, then add 2 parts of multifunctional reactive diluent EM222 / EM222-TF (DPGDA) Stir at 600r / min for 10min, tha...

Embodiment 3

[0070] The present embodiment provides a wood coating, which comprises the following components in parts by weight:

[0071]

[0072] Its preparation method comprises the following steps:

[0073] (1) Epoxy acrylate, polyester acrylate, polyurethane acrylate and multifunctional reactive diluent EM231\EM231-TF (TMPTA) are dropped into the reactor, stirred at 800r / min for 10min to obtain compound I;

[0074] (2) Stir the mixture I, dispersant, defoamer, leveling agent, antioxidant and photoinitiator at 800r / min for 10min to obtain mixture II;

[0075] (3) Stir the mixture II, 1250-mesh transparent powder, 1000-mesh talcum powder and anti-settling agent for 30 minutes at 1200 r / min to obtain a mixture III with a dispersion fineness of ≤50 μm;

[0076] (4) Stir the mixture III and 2.4 parts of multifunctional reactive diluent EM222 / EM222-TF (DPGDA) at 600r / min for 5min, then add 2 parts of multifunctional reactive diluent EM222 / EM222-TF (DPGDA) Stir at 600r / min for 10min, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com