Flue gas purification equipment for regenerative chamber of high-temperature rotary kiln

A flue gas purification and rotary kiln technology, applied in lighting and heating equipment, waste heat treatment, gas treatment, etc., can solve the problems of poor purification efficiency and achieve good purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

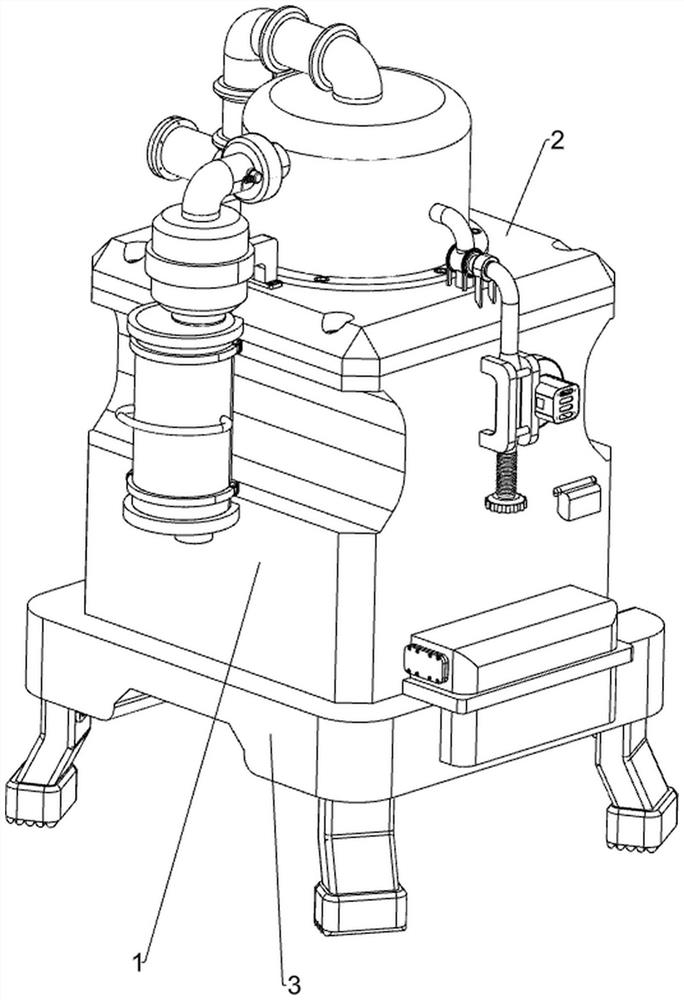

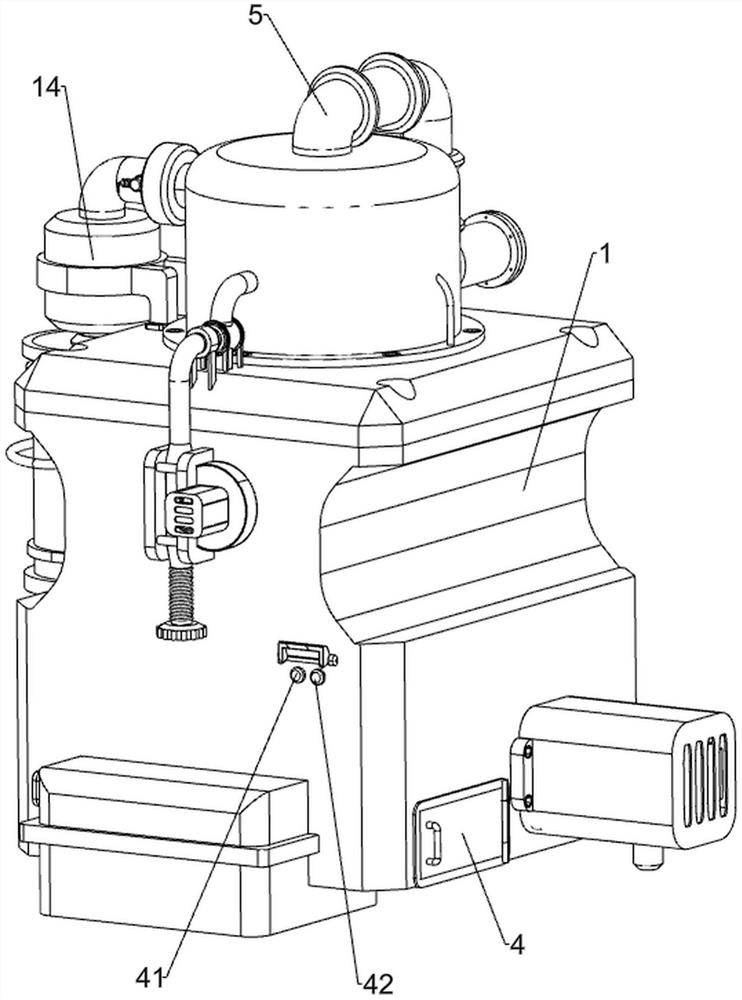

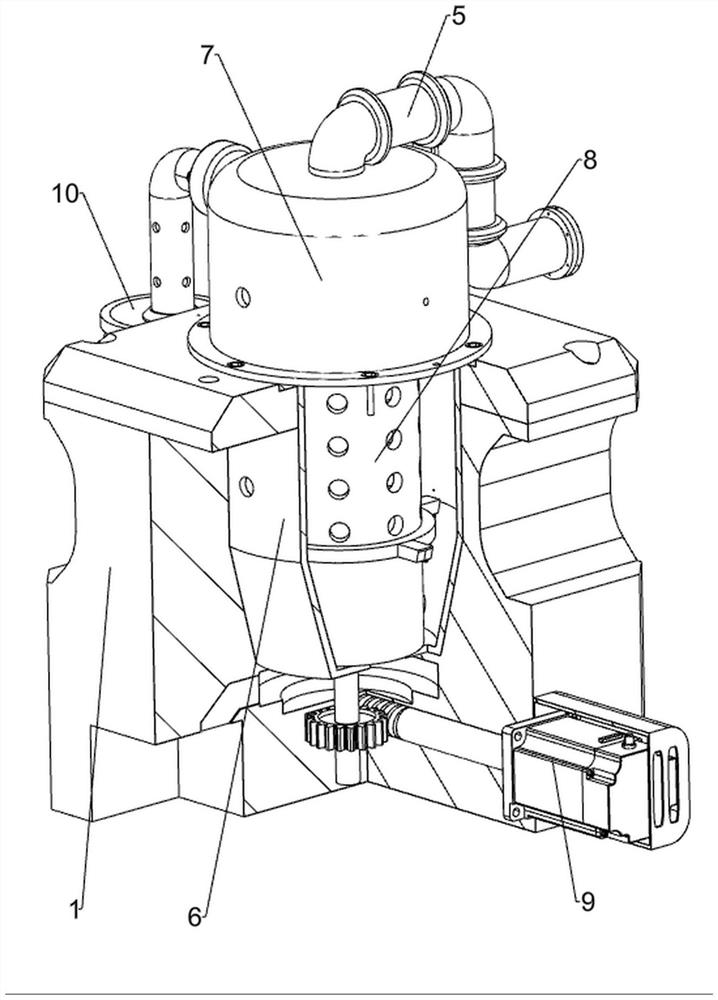

[0039] A high-temperature rotary kiln regenerator flue gas purification equipment, such as Figure 1-Figure 5 As shown, it includes installation base 1, sealing top plate 2, support bottom plate 3, start button 41, stop button 42, air intake pipe 5, sealing bottom cylinder 6, installation top cylinder 7, purification vertical cylinder 8, drive mechanism 9 and filter mechanism 10. The top of the installation base 1 is connected with the sealing top plate 2 by means of bolts, the bottom of the installation base 1 is fixedly connected with the support base plate 3, and the lower right part of the front side of the installation base 1 is fixed with the start button 41 and the stop button 42, the stop button 42 is located at the start On the right side of the button 41, the inner middle part of the installation base 1 is fixedly connected with the sealing bottom cylinder 6, and the upper part of the sealing bottom cylinder 6 is connected with the installation top cylinder 7 by means...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 6-Figure 9 As shown, a scraper mechanism 11 is also included, and the scraper mechanism 11 includes a charging box 111, a discharge square tube 112, a perforated drum 113, a material removal stand 114, a limit wave plate 115, and a scraper brush plate 116, limit post 117, return guide rod 118 and return spring 119, the lower side of the front part of the installation base 1 is embedded with a charging box 111, the middle of the rear part of the charging box 111 is connected with a discharge square tube 112, and the vertical shaft 93 is fixed The upper part is fixed with a perforated drum 113, the discharge square tube 112 is set on the perforated drum 113, the discharge square tube 112 is connected with the perforated drum 113 in rotation, and the middle of the front side of the top of the perforated drum 113 passes through the bolt. The material removal stand 114 is connected in the same way, and the inner top wall of the puri...

Embodiment 3

[0049] On the basis of embodiment 1 and embodiment 2, such as Figure 6 , Figure 12 and Figure 13 As shown, a desulfurization mechanism 13 is also included, and the desulfurization mechanism 13 includes a water pump 131, a water flow sensor 132, a shunt pipe 133, a liquid storage tank 134, a spherical solenoid valve 135, a liquid level sensor 136, an atomizing nozzle 137 and The absorption sieve plate 138, the water pump 131 is fixedly connected to the upper middle part of the front side of the installation base 1, the diversion pipe 133 is connected to the middle part of the purification vertical cylinder 8, and the diversion pipe 133 is connected with the water pump 131, and the water flow is fixed in the middle of the top front side of the sealing top plate 2 The sensor 132 and the water flow sensor 132 can detect the water flow in the shunt pipe 133. A liquid storage barrel 134 is fixedly connected in the middle of the lower side of the rear part of the installation bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com