+/-800kV extra-high voltage direct current line live working squirrel-cage tubular bus wire lifting clamp

A technology of UHV DC and live work, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of unsafety, inconvenient operation and use, and achieve the effect of easy operation and construction, and avoid indentation and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

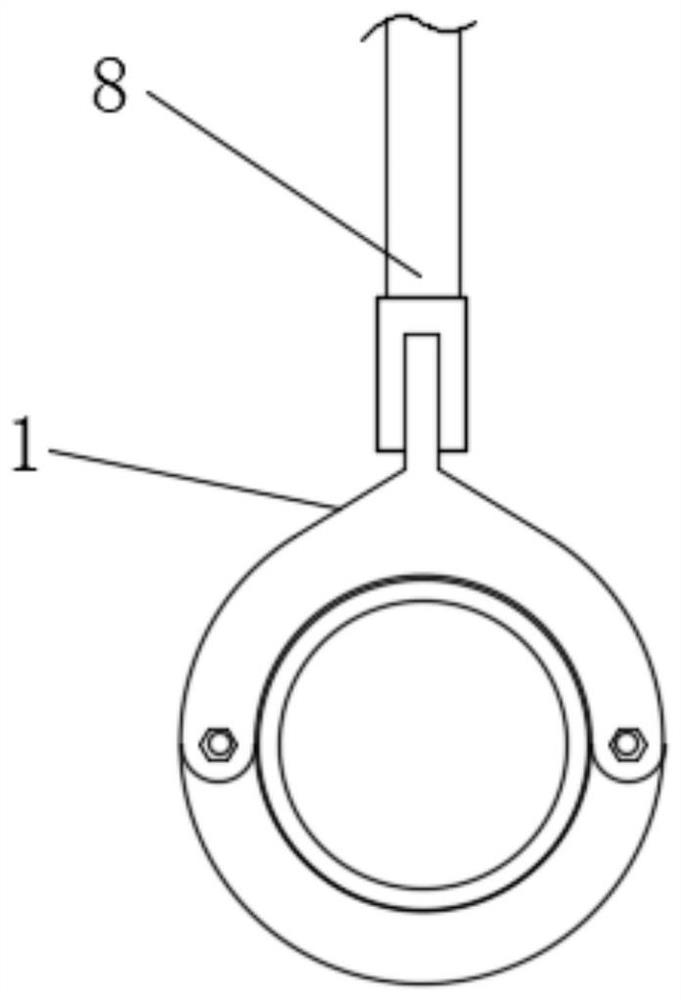

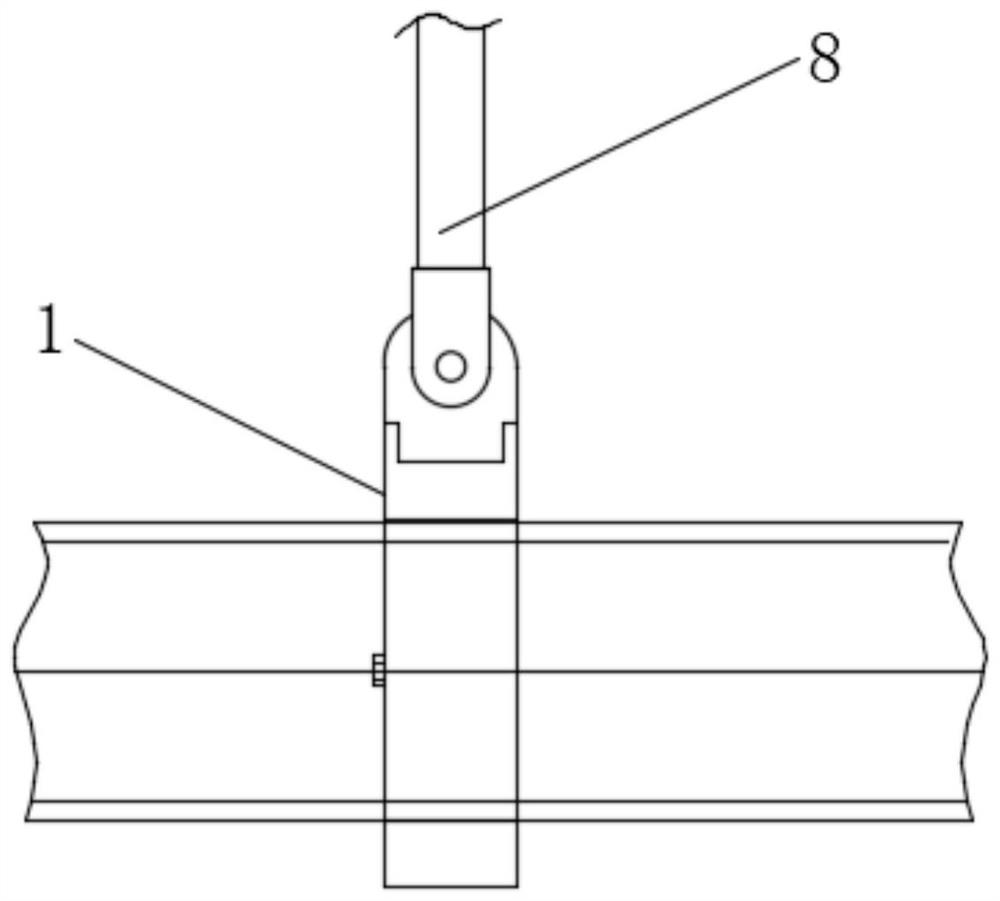

[0044] see Figure 1~5 , a ±800kV UHV DC line live working squirrel-cage tube-feeder clamp, including

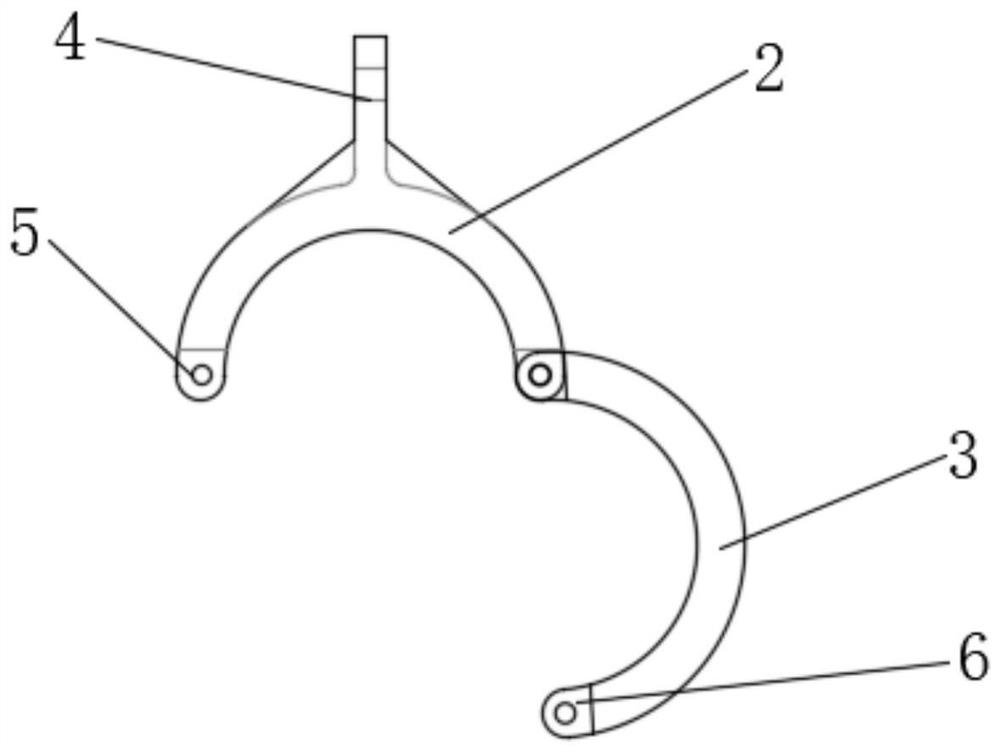

[0045] The wire lifting card body 1 is in the form of a ring-shaped squirrel cage, and it is composed of two symmetrically arranged clamp fixing covers 2 and clamp flip 3, and the clamp fixing cover 2 is located at the upper end of the clamp flip 3;

[0046] The docking assembly is arranged at the junction of the fixture fixing cover 2 and the fixture flip cover 3, and it is fixedly connected to the fixture by the docking grooves 5 respectively opened at both ends of the fixture fixing cover 2. The butt bumps 6 at both ends of the flip cover 3 are formed;

[0047] Lifting assembly, which is used to lift and lift the wire lifting card body 1, and is vertically connected to the connecting ear 4 by the connecting ear 4 fixedly welded on the middle part of the upper end of the clamp fixing cover 2 Insulation rod 8 on the composition.

[0048] In the embodiment of the present ...

Embodiment 2

[0053] A squirrel-cage type pipe-feeder lifting card for live working on a ±800kV UHV DC line, the design method of which includes the following steps:

[0054] Step 1. Material selection. According to the 50KN work load to be borne, choose to use titanium alloy material, and the design parameter is σ s =824Mpa, σ b =902MPa, fixture center distance 212mm;

[0055] Step 2. Calculation of the strength at the cross-section, intercepting a cross-section with a length of 60 mm and a width of 30 mm;

[0056] The section moment of inertia is: I Y =ab 3 / 12=135000mm 4

[0057] The flexural section modulus of this section is W=ab 2 / 6=9000mm 3

[0058] Step 3. The bending moment applied to the section is:

[0059] M=(P / 2)×96=(50000 / 2)×96×2.5=6000000N.mm

[0060] Then the bending stress on the section is:

[0061] σ=M / W

[0062] σ=667Mpas =824Mpa

[0063] Step 4. Calculate the cross-section of the lug at the top of the fixture, and intercept the hole with an inner diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear force | aaaaa | aaaaa |

| Shear force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com