Matching structure of brushless wiper motor end cover and reducer shell

A technology of motor end cover and matching structure, applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of hidden danger of motor water ingress, low production efficiency, poor sealing, etc., and achieve positioning accuracy Low requirements, improved waterproof performance, improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below by means of drawings and examples.

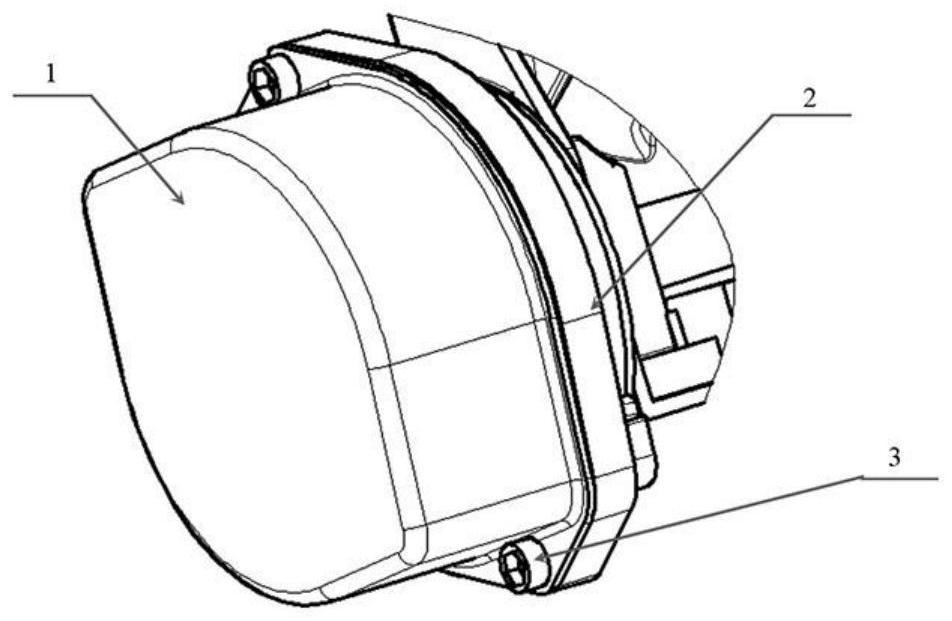

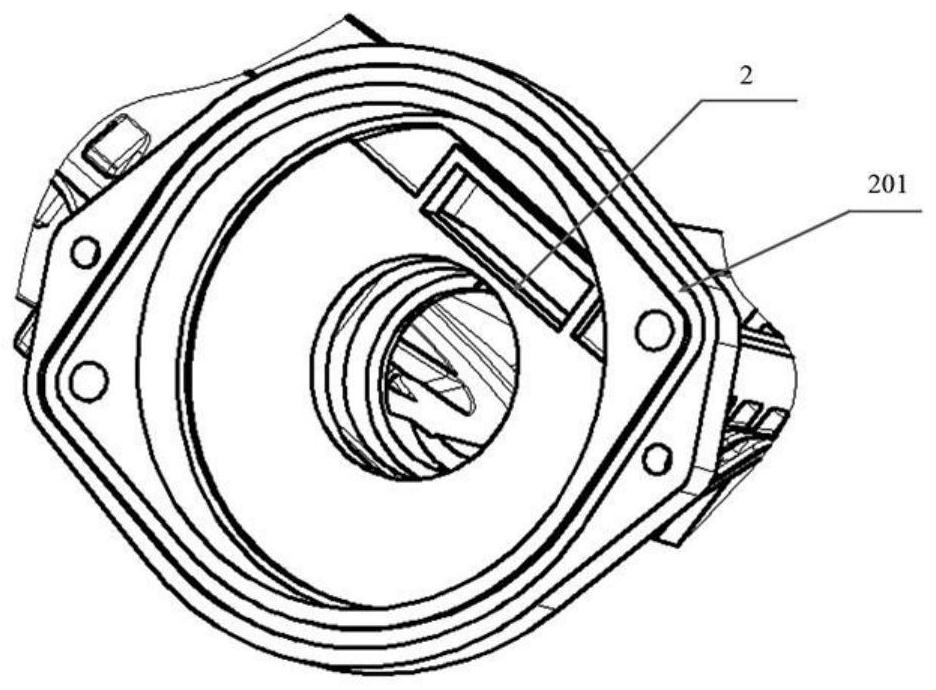

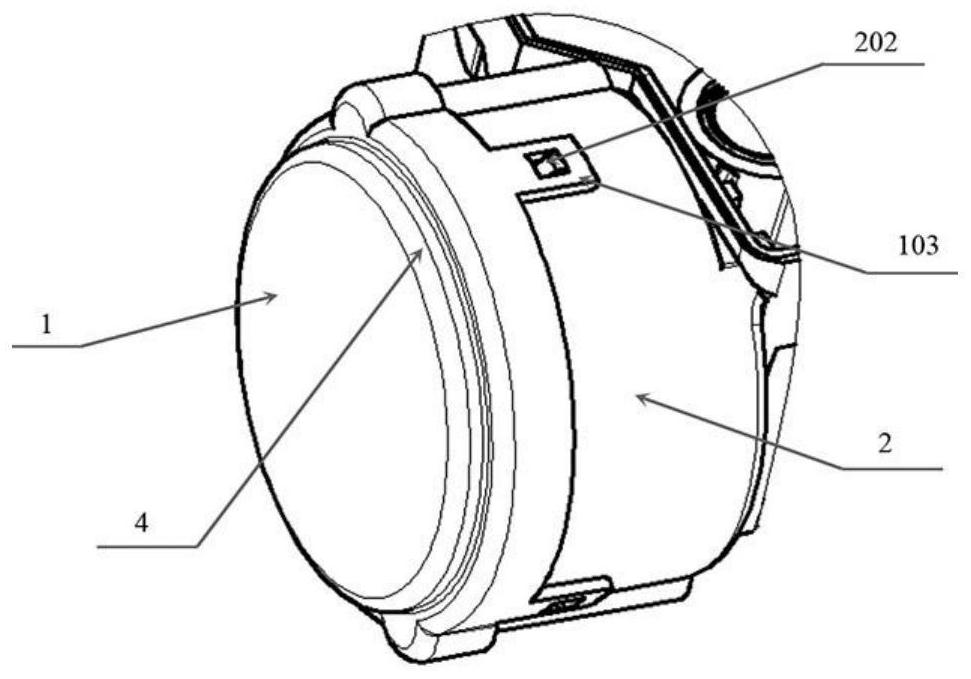

[0024] see Figure 3-5 , a matching structure of a brushless wiper motor end cover and a reduction housing, including an end cover 1 and a reduction housing 2, the end cover 1 is provided with an end cover glue groove 101 and a limiter 102, and at least three a buckle 103; the shell 2 is provided with a boss 202 corresponding to the buckle 103; the three buckles 103 are uniformly distributed around the structure; the end cover 1 is a plastic part, and laser marking is realized on the plane of the end cover mark.

[0025] When assembling, first apply the sealant in the glue coating groove 101 of the end cover, and directly buckle the end cover 1 into the reduction housing 2, and the limit platform 102 in the end cover 1 directly contacts with the surface of the reduction housing 2 for limiting position; in this process, the position of the reduction housing 2 will go deep into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com