Molten aluminum pouring quantitative control equipment

A technology of quantitative control and aluminum liquid, which is applied in the direction of casting equipment, metal processing equipment, manufacturing tools, etc., can solve problems affecting the quality of workpieces, and achieve the effect of improving comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached Figure 1-4 The application is described in further detail.

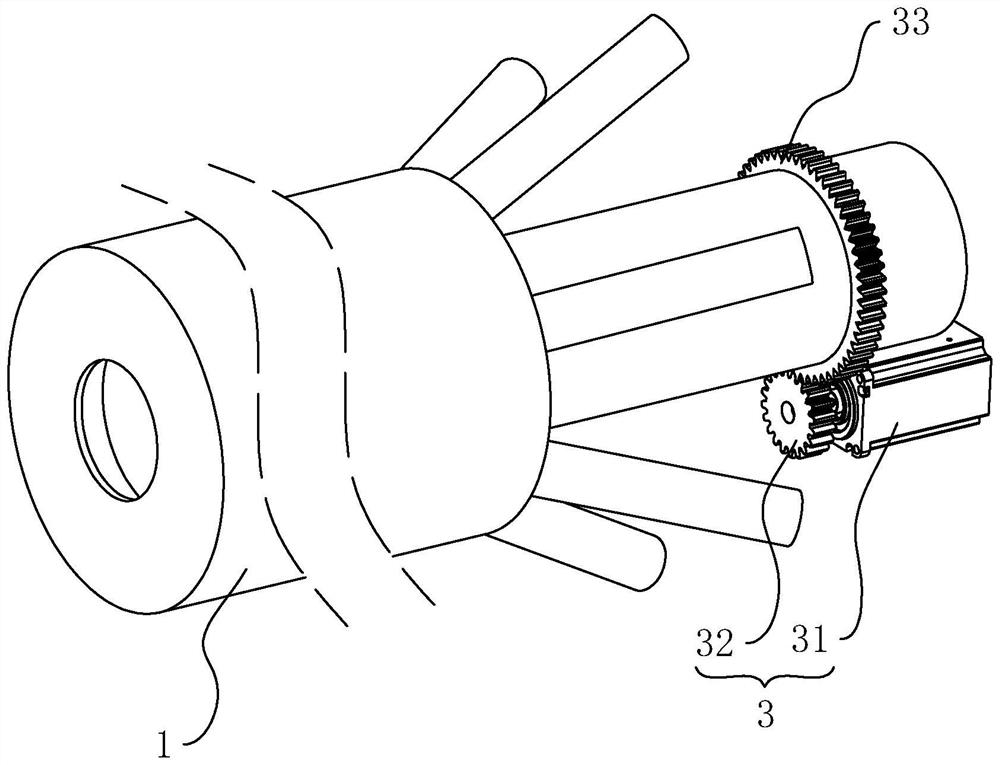

[0032] The embodiment of the present application discloses a dosing control device for molten aluminum pouring. refer to figure 1 The dosing control equipment for molten aluminum pouring includes a drum body 1 which is hollow inside, and a filter residue mechanism is arranged in the drum body 1, and the residue filter mechanism includes a slag removal part 2 for removing aluminum slag in the drum body 1 by rotation and a slag removal part for driving 2 Rotating drive part 3.

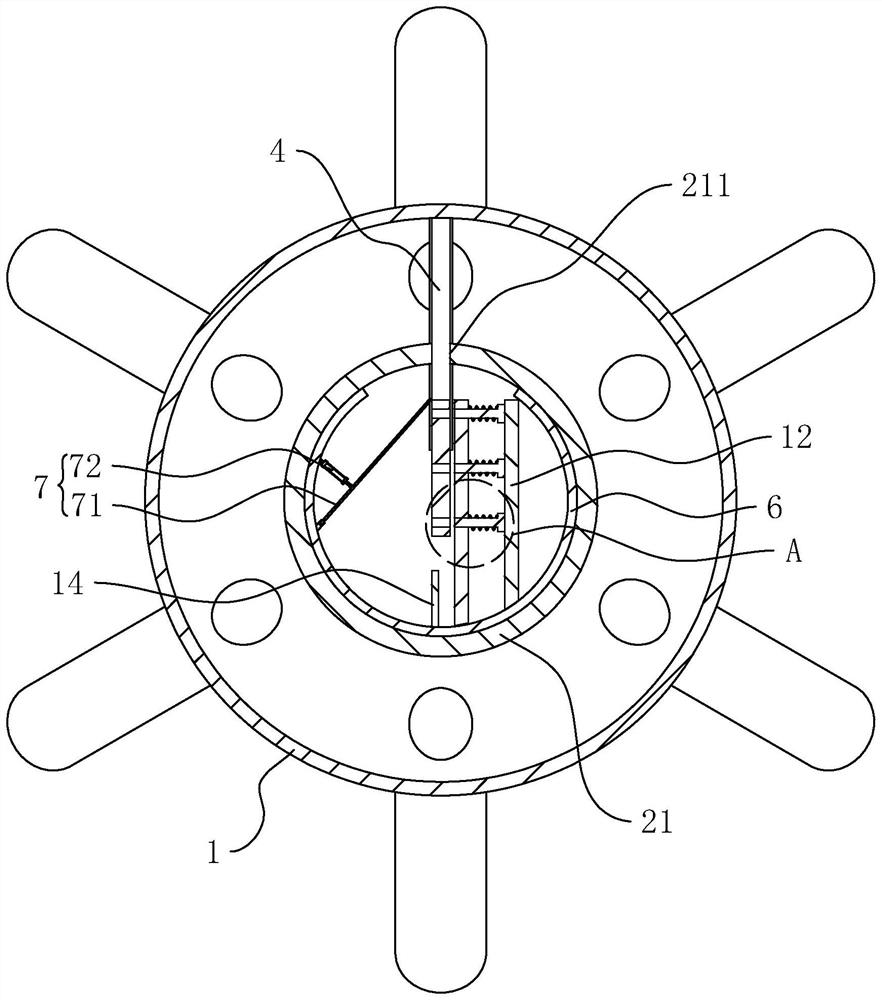

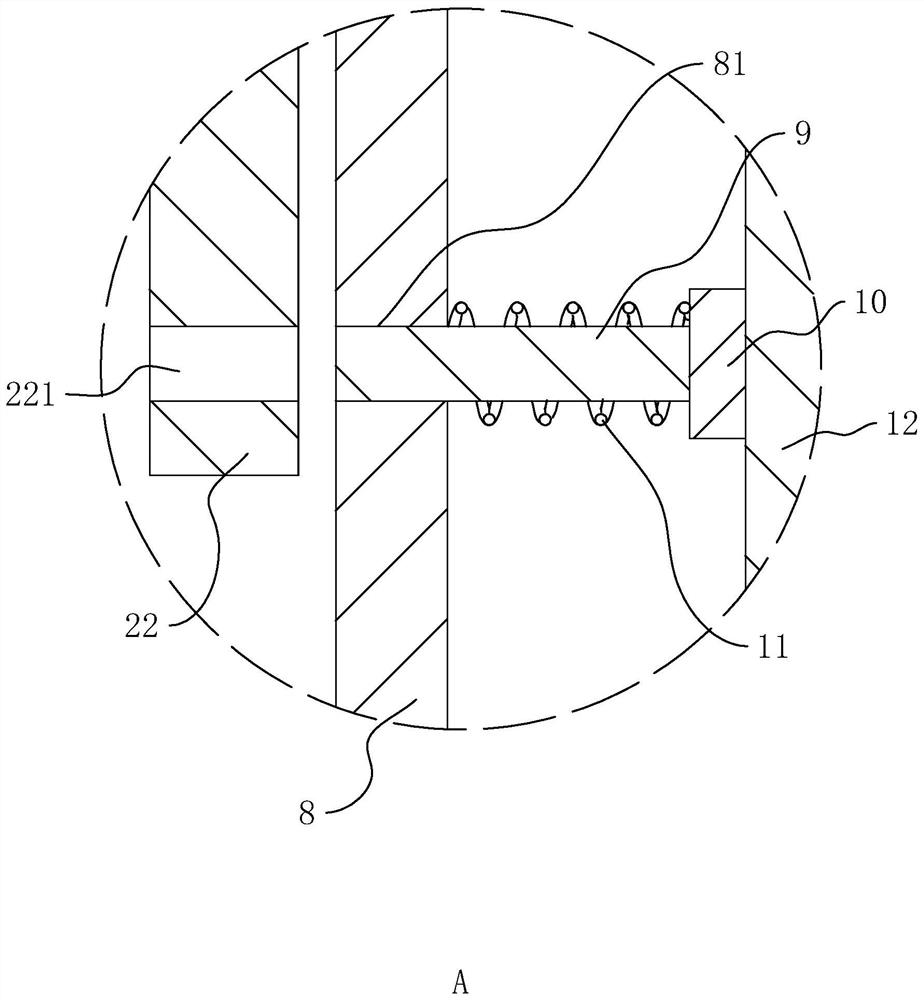

[0033] refer to figure 2 , image 3 and Figure 4 The slag removal part 2 includes a slag removal cylinder 21 located in the drum body 1 and coaxially arranged therewith. There is a distance between the slag removal cylinder 21 and the circumferential inner wall of the drum body 1. One end of the slag removal cylinder 21 is closed and the other end is open. And rotate and pass out the afterbody of drum b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com