A welding process for h-shaped steel

A welding process, H-beam technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of high labor intensity, low production efficiency, increased safety hazards, etc., to improve reset efficiency, compact structure, improve process safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0040] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0041] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

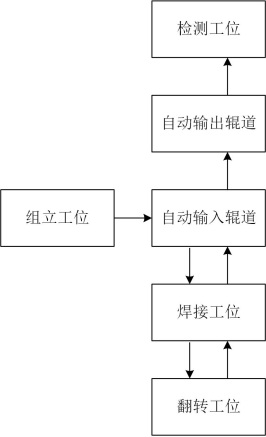

[0043] combined with figure 1 , present embodiment provides a kind of H-beam welding process, comprises the following steps:

[0044] Step S1, assembling: send one web and two wing plates to the assembling station, and perform automatic positioning, clamping, and spot welding through the automatic assembling equipment to complete the assembling of the H-beam;

[0045] Step S2, single-sided welding: put the assembled H-shaped steel horizontally into the automatic input roller table, enter the welding station through the automatic transmission roller table, and perform single-sided welding on the web and wing plates through automatic welding equipment;

[0046] Step S3, double-sided welding: the H-shaped steel welded on one side enters the turning station, and when all the H-shaped steel welded on one side enters the turning station, the turning equipment on the turning station lifts the H-shaped steel and turns it over 180° After that, it is re-sent to the welding station, and...

Embodiment 2

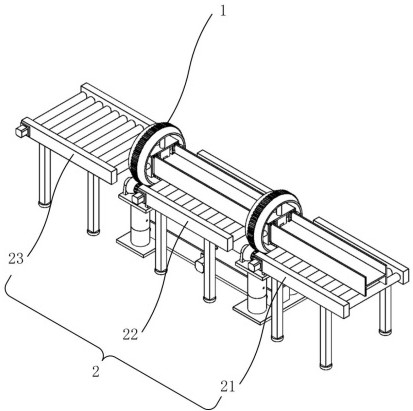

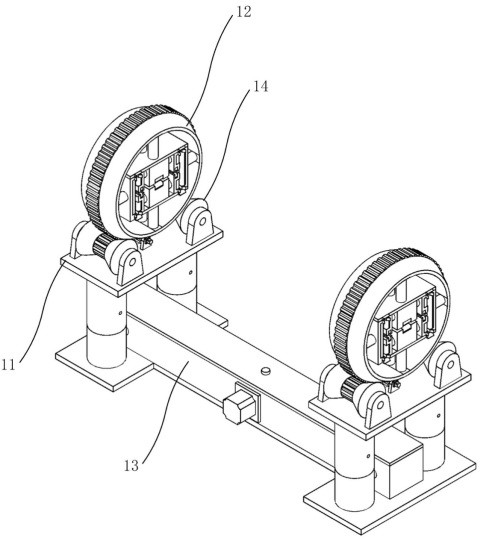

[0050] combined with figure 2 And attached image 3 , the present embodiment provides a turning device applicable to embodiment 1, the specific technical solution is as follows, the turning device includes a turning mechanism 1 and an automatic conveying roller set 2, and the turning mechanism 1 includes a set of rollers arranged at intervals along the conveying direction Two lifting platforms 11, the two lifting platforms 11 are respectively provided with clamping and rotating mechanisms 12, and the automatic conveying roller table set 2 includes a first roller table 21, a second roller table 22 and a third roller table 23, The first roller table 21 is arranged at one end of the turning mechanism 1 and docked with the automatic welding equipment. An infrared sensor (not shown in the figure) is arranged at the docking point, and the third roller table 23 is arranged at the turning point. At the other end of the mechanism 1 , the second roller table 22 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com